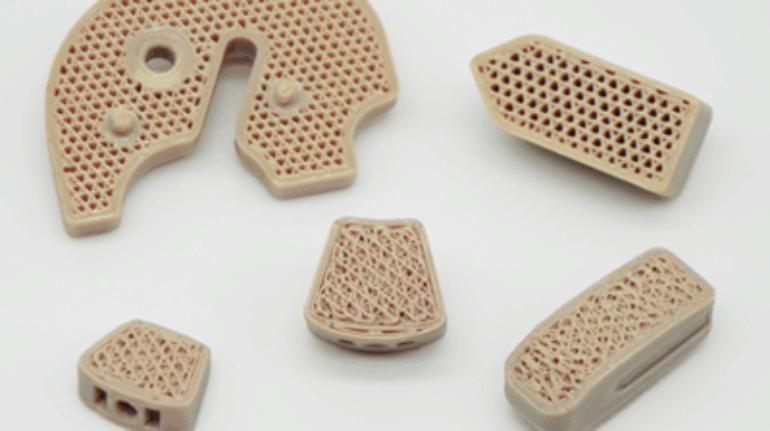

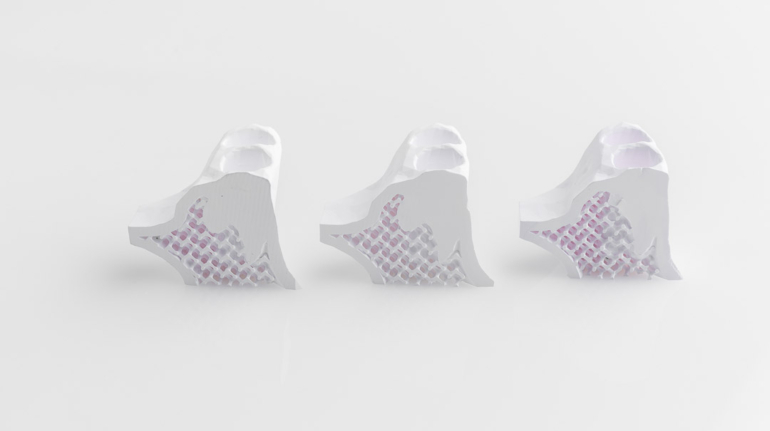

SprintRay Crown by BEGO – a Ceramic-filled Hybrid Material for Dentistry

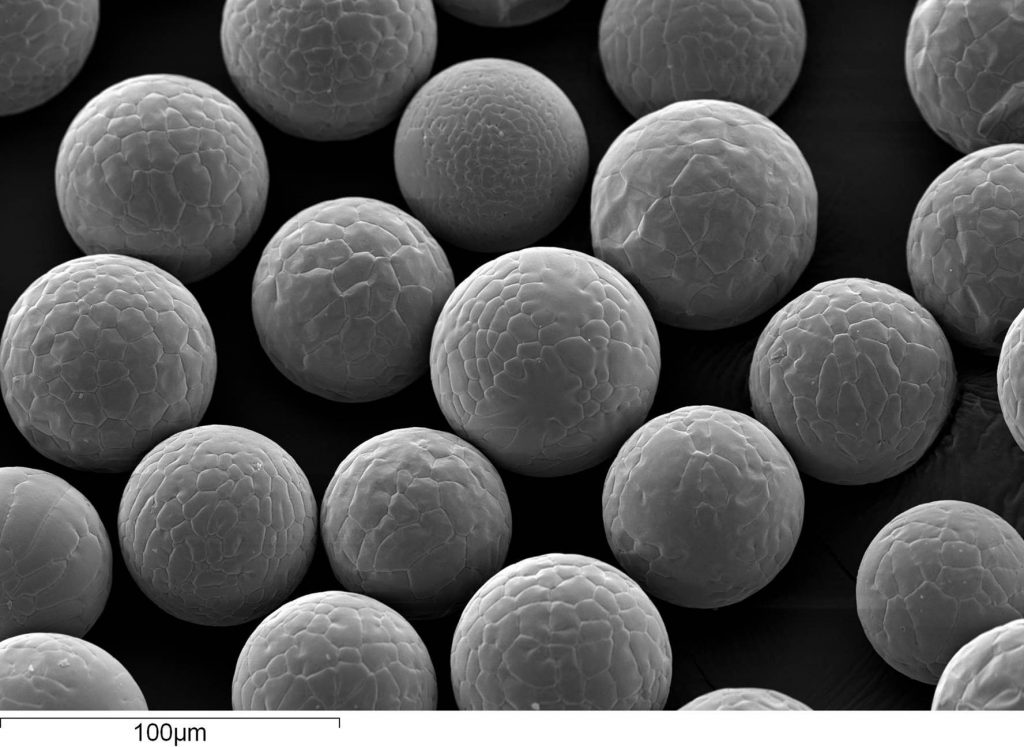

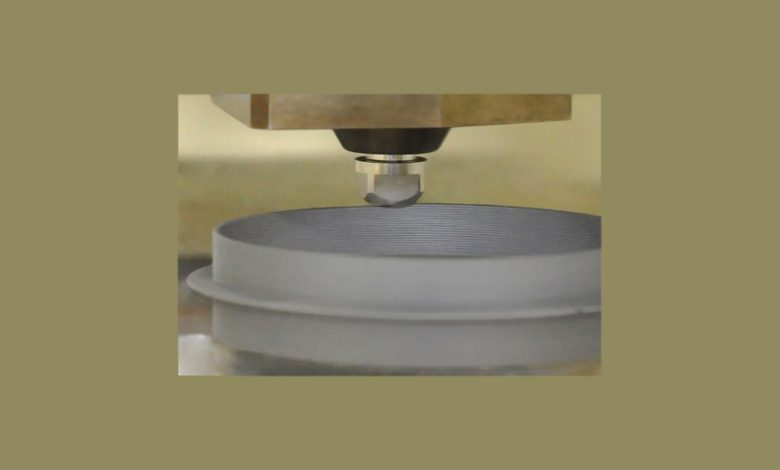

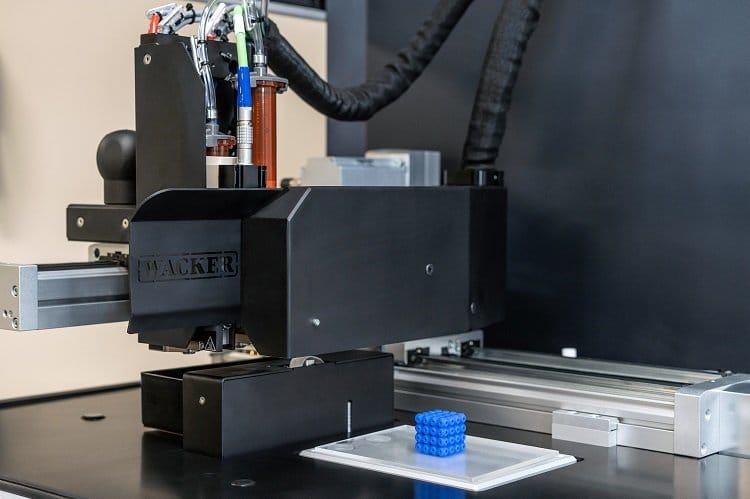

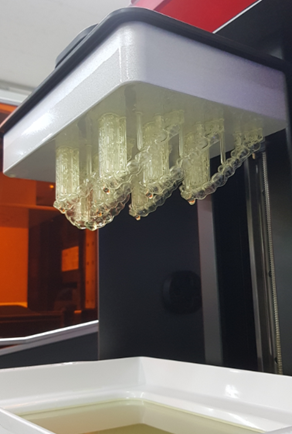

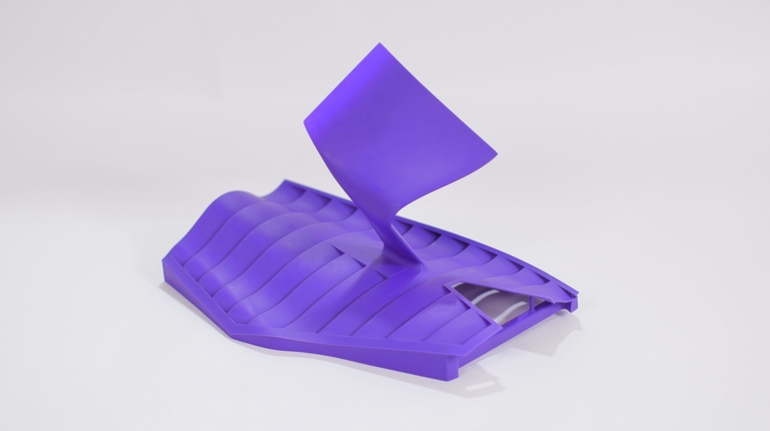

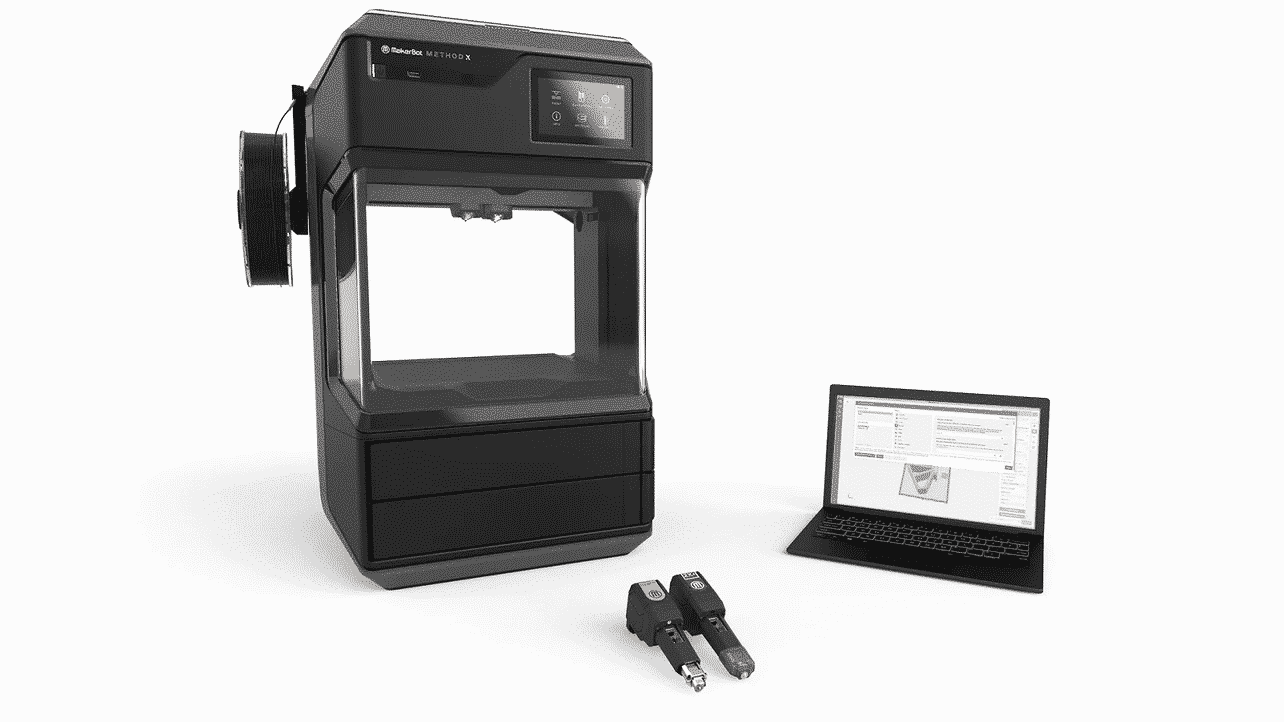

SprintRay has released SprintRay Crown by BEGO – a 3D printing resin developed to help improve the quality, and accessibility, of customized restorative care in digital dentistry. The SprintRay Crown by BEGO hybrid material was developed through the collaboration of the two companies – SprintRay, a dental technology company building end-to-end 3D printing ecosystems, offering manufacturing solutions such as dental 3D printers, 3D printing software, curing technology, washing systems, and materials, and BEGO, a leading specialist in the field of prosthodontics and implant dentistry.