The findings, published by a University College London (UCL)-led research team, improve the prospects of how 3D printers could be integrated into rapid-paced clinical settings for the on-demand production of personalized medicines. For the current study, the researchers loaded printlets (printed tablets) with paracetamol – one of many medicines that can be produced using 3D printing.

One of the leading techniques for 3D printing is vat photopolymerization, which affords the highest resolution for complexity at microscales, and also suits many medications as it does not require high heat. For printing medicines, the technique uses a resin formulation, constituting the required drug dissolved in a solution of a photoreactive chemical, activated by light to solidify the resin into a printed tablet.

But vat polymerization has been hampered by slow printing speeds, due to its layer-by-layer approach.

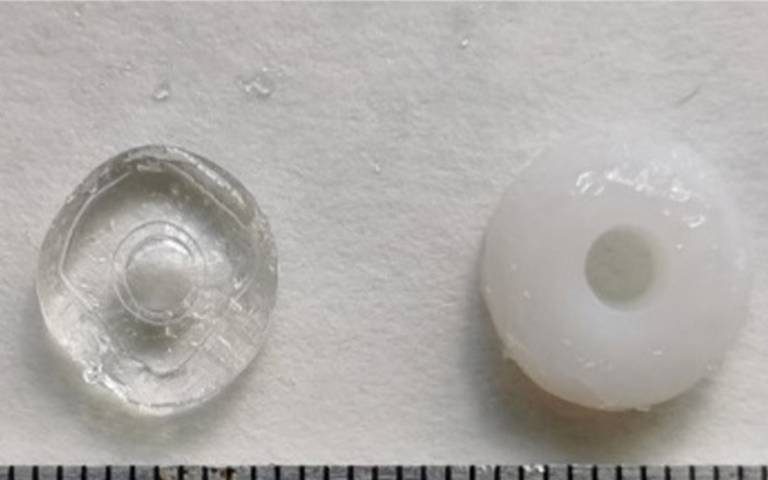

This 3D printed, personalized medicine was enabled by the development of a volumetric 3D printing approach, a new vat polymerization technique that prints the entire object all at once – reducing the printing speed from multiple minutes to between seven and 17 seconds (depending on the resin composition selected).

Manufacturing on Demand

This works by shining multiple images of the object viewed at different angles, onto the resin. The amount of light shone gradually accumulates until it reaches a point at which polymerization occurs. By adjusting the intensity of light at different angles and overlaps, all points of the 3D object in the resin can reach this threshold at the same time, causing the entire 3D object to solidify simultaneously.

The study is currently led by Professor Abdul Basit (UCL School of Pharmacy), and also involves researchers at Universidade de Santiago de Compostela as well as FabRx, a UCL spin-out co-founded by three members of the UCL research team.

The Basit lab has previously 3D printed medicines such as polypills to help people who need to take multiple medications each day, and pills with braille patterns to help the visually impaired.

Co-lead author Dr. Alvaro Goyanes (UCL School of Pharmacy, FabRx, and Universidade de Santiago de Compostela) said: “Personalized 3D printed medicines are evolving at a rapid pace and reaching the clinic. To match the fast-paced clinical environment, we have developed a 3D printer that produces tablets within seconds. This technology could be a game-changer for the pharmaceutical industry.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment