Insights

LAMÁQUINA’s 3D printed ceramic tiles complete Sagrada Família’s tallest tower Construction 3D Printing

On February 20, 2026, the final arm of the cross was lifted onto the Tower of Jesus Christ at the Sagrada Família in Barcelona, marking the completion of the cathedral’s exterior and the culmination of 144 years of construction. The cross now crowns the structure at 172.5 meters, making it the world’s tallest church. The robotic 3D printed ceramic tiles that form the tower’s white glazed ceramic skin were developed by LAMÁQUINA in collaboration with Ceramica Cumella.

News

Follow us on Social Media

Popular Posts

Category

We realize your creation

FacFox provides one-stop solution with comprehensive on-demand manufacturing capabilities and data-driven analysing technologies, see our available service, feel free to reach us to realize your creation!

3D Printing

Plastic 3D Printing is one of the fastest and most cost-efficient methods for iterative design, prototyping, and customizable products.

CNC Machining

Accurate CNC milling and turning processes with low-cost and fast turnaround time to deliver high quality, on-demand parts.

Injection Molding

Produces end products in various quantity(500 to 100,000+) and low unit cost with Plastic Injection and Metal Injection

Urethane Casting

Produces end-use, rigid or flexible plastic parts with high durability, fast lead times, and production-level quality.

Metal 3D Printing

Ideal for metal parts with very complex geometries or customizable features. Industrial grade printers and multi-functional materials.

Sheet Fabrication

Metal bending, punching, laser cutting, stamping and plastic thermal forming, ranging from prototyping to mass production.

Metal Casting

Produce small batched parts with investment casting and mass production with die casting or forging.

3D Scanning

We provide a variety of 3D laser scanning solutions to suit virtually any type of object from tiny to large.

Most Viewed

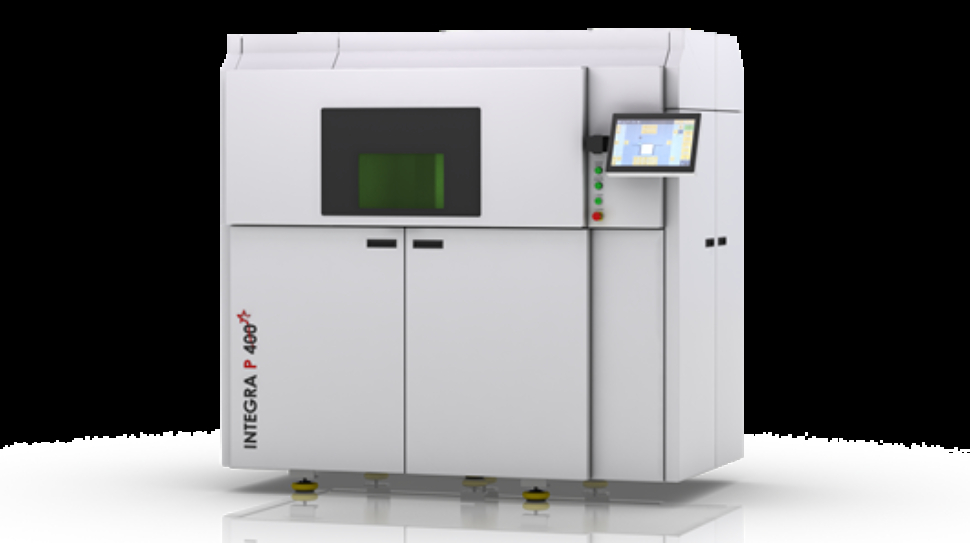

Here is EOS’s new Integra P 400, a North American-exclusive production system 3D Printer Hardware

EOS North America is introducing the Integra P 400 polymer Additive Manufacturing (AM) platform developed to meet customer demands specifically for the North American market. The fast, flexible powder bed AM platform gives organizations the ability to process applications using a wide range of materials that offer characteristics such as high abrasion or chemical resistance, low-temperature performance, high elasticity, and transparency.

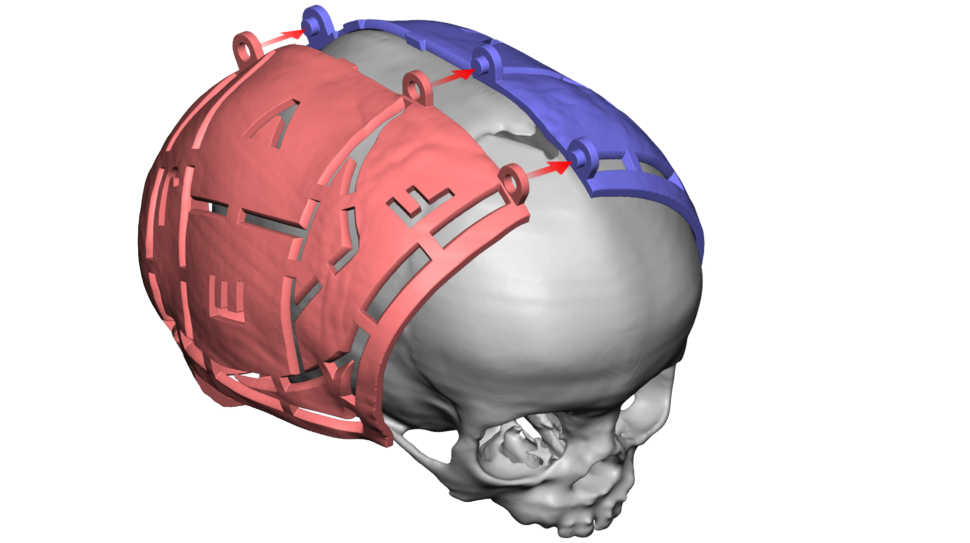

3D Systems Expands Virtual Surgical Planning (VSP) Service to Include Cranial Applications AM Software

Leading 3D printer manufacturer 3D Systems has expanded its Virtual Surgical Planning (VSP®) service to include VSP Cranial for cranial and craniofacial procedures. VSP Cranial is 510(k) cleared for use in the operating room and enables surgeons to create a virtual pre-surgical plan that can be instrumented with sterilizable, patient-specific 3D printed anatomical models, guides and templates. The use of VSP Cranial on these complex and sensitive procedures enables doctors to plan around and become familiar with a patient’s specific anatomy, and is intended to facilitate the pre-surgical planning process as well as the transfer of that plan to the operating room. By supplying surgeons with informative digital tools and accurate 3D printed surgical guides, VSP Cranial is designed to help doctors deliver improved surgical outcomes.

The Małopolska’s Virtual Museum Shares 2,000+ Free 3D Models of Cultural Heritage

Wirtualne Muzea Małopolski (The Małopolska’s Virtual Museums) is a long-run innovative project aiming to digitalize the finest and most valuable items of cultural heritage from museums in the Małopols ...

Zenith Tecnica and Air New Zealand to 3D print titanium aircraft components Aerospace

New Zealand-based titanium additive manufacturing company Zenith Tecnica has partnered with Air New Zealand to investigate the use of electron beam melting (EBM) for manufacturing aircraft parts and tools.

Amazing (Not 3D Printed) Morpheus Hotel Serves as Base for 3D Structures of Tomorrow 3D Printing Processes

It’s clearly not 3D printed in any way – although it is very likely that Zaha Hadid architects used 3D printing for many parts of the building’s physical modeling and prototyping – but the Morpheus Hotel and Tower in Macau is probably one of the clearest example of what can be achieved with the […]

Rugged 3D Company Relocates to Youngstown Business Incubator

Collin Boring, the founder and CTO of YOUNGSTOWN-3D printing company Rugged 3D, was looking for a suitable location to relocate his company from San Francisco to other places-and found that Youngstown ...

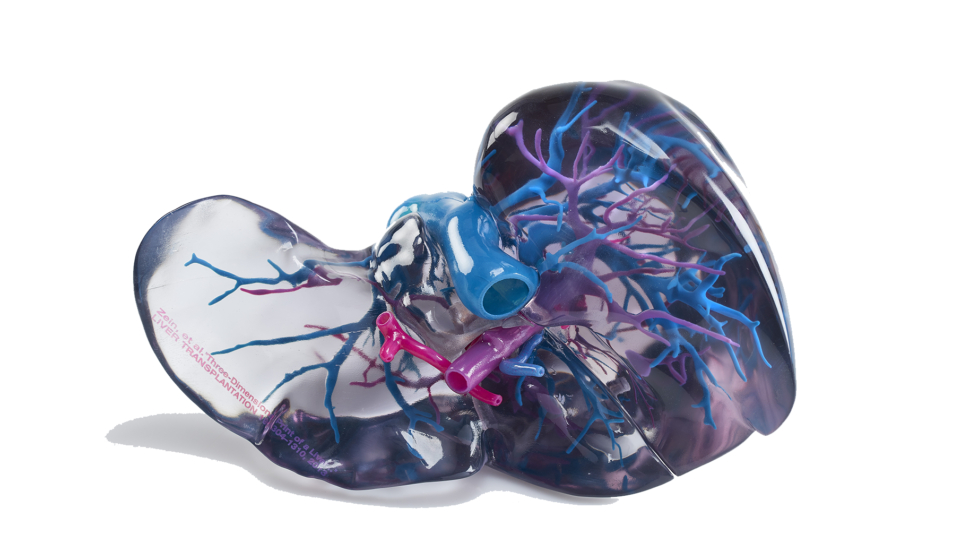

Stratasys Releases White Paper on Benefits of Surgical 3D Printed Models AM Software

The use of surgical 3D printed models for anatomical planning has a history going back more than two decades, but it has primarily been pursued by a narrow set of research hospitals. Recently, int ...

RIZE Inc. unveils full-colour XRIZE industrial 3D printer, new materials and more 3D Printing Events

Boston-based 3D printing company RIZE Inc. today announces a slew of new products, including the brand new XRIZE industrial desktop 3D printer with full-colour capabilities. In addition to the 3D printer launch, the company has also introduced a range of new materials, including RIZIUM CARBON and RIZIUM ENDURA, as well as the RIZE CONNECT cloud platform.