ETH Zurich-Led Study Produces Functional 3D Printed Ear Cartilage, Paving Way for Clinical Reconstruction

Researchers from ETH Zurich, the Friedrich Miescher Institute, and the Cantonal Hospital of Lucerne have leveraged 3D printing to engineer elastic ear cartilage with mechanical properties closely matching natural tissue. Using human ear cartilage cells, the team produced constructs that retained shape and flexibility in animal models for six weeks, marking a significant step toward patient-specific, lab-grown ear replacements.

CollPlant targets formulation bottleneck with new DLP bioprinting kit

Regenerative medicine specialist CollPlant has launched BioFlex, a ready-to-print bioprinting kit built on rh-collagen, aimed at researchers working on tissue engineering and regenerative medicine.

LAMÁQUINA’s 3D printed ceramic tiles complete Sagrada Família’s tallest tower Construction 3D Printing

On February 20, 2026, the final arm of the cross was lifted onto the Tower of Jesus Christ at the Sagrada Família in Barcelona, marking the completion of the cathedral’s exterior and the culmination of 144 years of construction. The cross now crowns the structure at 172.5 meters, making it the world’s tallest church. The robotic 3D printed ceramic tiles that form the tower’s white glazed ceramic skin were developed by LAMÁQUINA in collaboration with Ceramica Cumella.

Croom Medical breaks ground on ACOT orthopaedic manufacturing and R&D facility in Limerick

Croom Medical, an Ireland-based contract manufacturer of orthopaedic implants, has broken ground on a 38,000-square-foot expansion at its manufacturing campus in Croom, County Limerick. Called the Advanced Centre of Orthopaedic Technologies (ACOT), the project marks the largest single investment in the company’s 42-year history. Construction is now underway, with completion expected by the end of 2026.

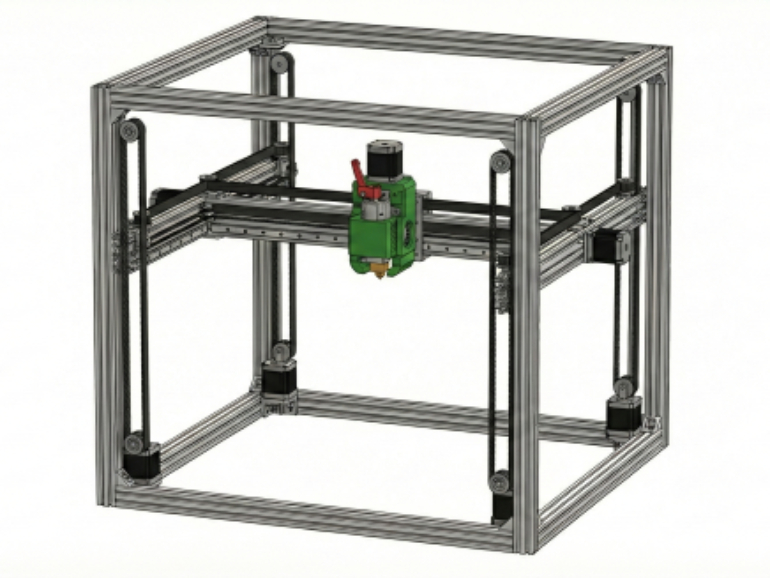

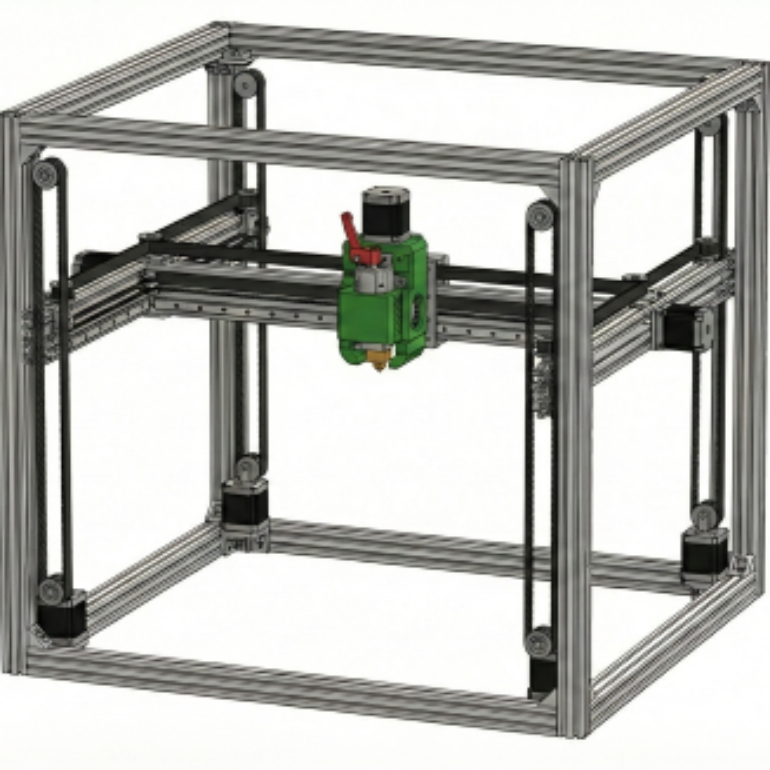

Sunnyday Technologies releases M3-CRETE open-source 3D concrete printer 3D Printer Hardware

Sunnyday Technologies is releasing M3-CRETE, a fully open-source concrete 3D printer built for field deployment and research validation. The project sits alongside CEMFORGE, Sunnyday Technologies’ AI-driven concrete formulation platform, which the firm positions as a mix-design engine for additive construction. Sunnyday Technologies publishes documentation, CAD files, and a draft bill of materials (BOM) to a public GitHub repository for customization and comment.

Stratasys Introduces Dental Anatomical Model Preset for Education and Clinical Training

3D printer OEM Stratasys has introduced a dental anatomical model preset designed for simulation-based education and clinical training. The multi-material 3D printed solution offers a synthetic alternative to cadavers, animal specimens, and stone models, addressing cost, variability, and ethical concerns that continue to affect traditional training environments.

3D printed pool makes a big splash in Australia Construction 3D Printing

While an outdoor swim might seem like a far-off dream to those of us trying to warm up in the Northern Hemisphere, it’s an essential cool-down tactic for Aussies at this time of year, with summertime temperatures in Western Australia soaring above 30°C. Most in the region will be doing their laps in standard in-ground pools, but soon a small number of locals will be able to say they’re swimming in the country’s first 3D printed pool.

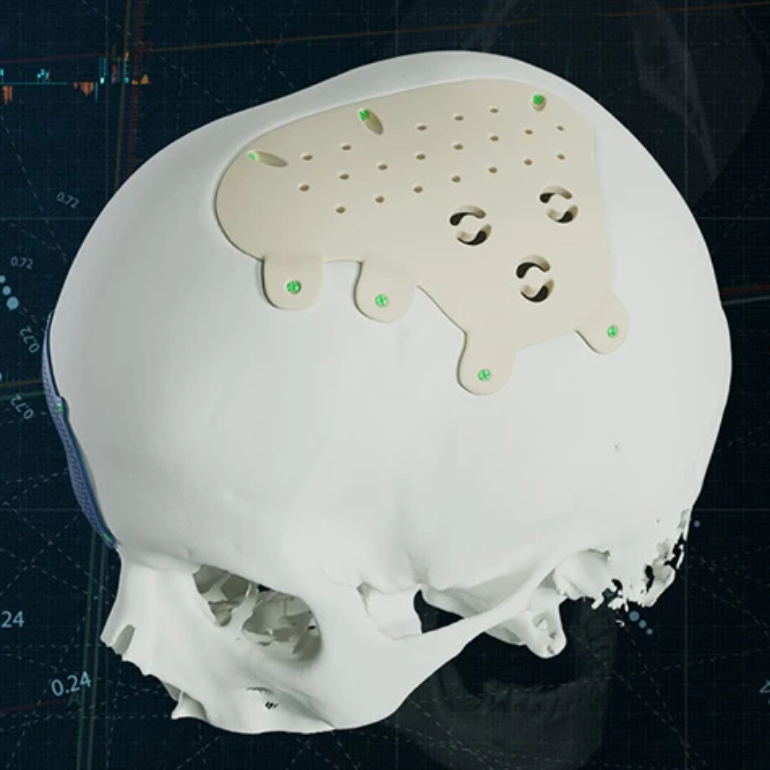

Materialise adds custom-made PEEK implants to cranio-maxillofacial portfolio

Materialise NV, a Belgium-based 3D printing software and medical device company, has introduced custom-made implants made from polyetheretherketone (PEEK) to its cranio-maxillofacial (CMF) portfolio. Surgeons can now select either titanium or the high-performance polymer for patient-specific reconstructions while using the same digital planning and case management system. Availability covers Europe, excluding Switzerland.