The Army provides a new type of polymer filament for commonly used desktop 3D printers. This advancement can save money and help quickly print critical parts when needed.

This research is also the cover story of the April edition of “Advanced Engineering Materials”, a monthly scientific journal that is peer-reviewed.

Historically, the strength and toughness of parts produced using these printers have been poor, which has not prevented people from using affordable printers to re-supply military parts on-demand, especially at deployment sites. The Army ’s new materials overcome these deficiencies, potentially allowing soldiers to use low-cost printers to manufacture parts that, once heated for hours, can obtain mechanical properties that are strong enough to withstand the harsh test of field operations.

Dr. Eric D. Wetzel said that this breakthrough was an important step for the Army’s expeditionary manufacturing industry. He led the emerging composite materials team and was responsible for the field of soldier materials research in the Army Research Laboratory of the US Army Combat Capability Development Command people.

Wetzel’s research covers a wide range of technical solutions that can enhance soldiers’ lethality by enhancing the way soldiers shoot, move, communicate, protect, and maintain themselves.

“The Army would like to be able to print parts in the field to simplify logistics by carrying digital part files instead of physical parts, but to date, the technologies for producing high-strength parts have not been practical in an expeditionary setting. These printers are too large, energy-hungry, delicate or messy for starters, and their feedstocks can require specialized storage requirements.”

This technology allows the Army to use affordable, simple printers to produce high-quality parts.

According to the paper, molten filament manufacturing or FFF is the most common additive manufacturing technique, but parts made using FFF lack sufficient mechanical integrity in most engineering applications.

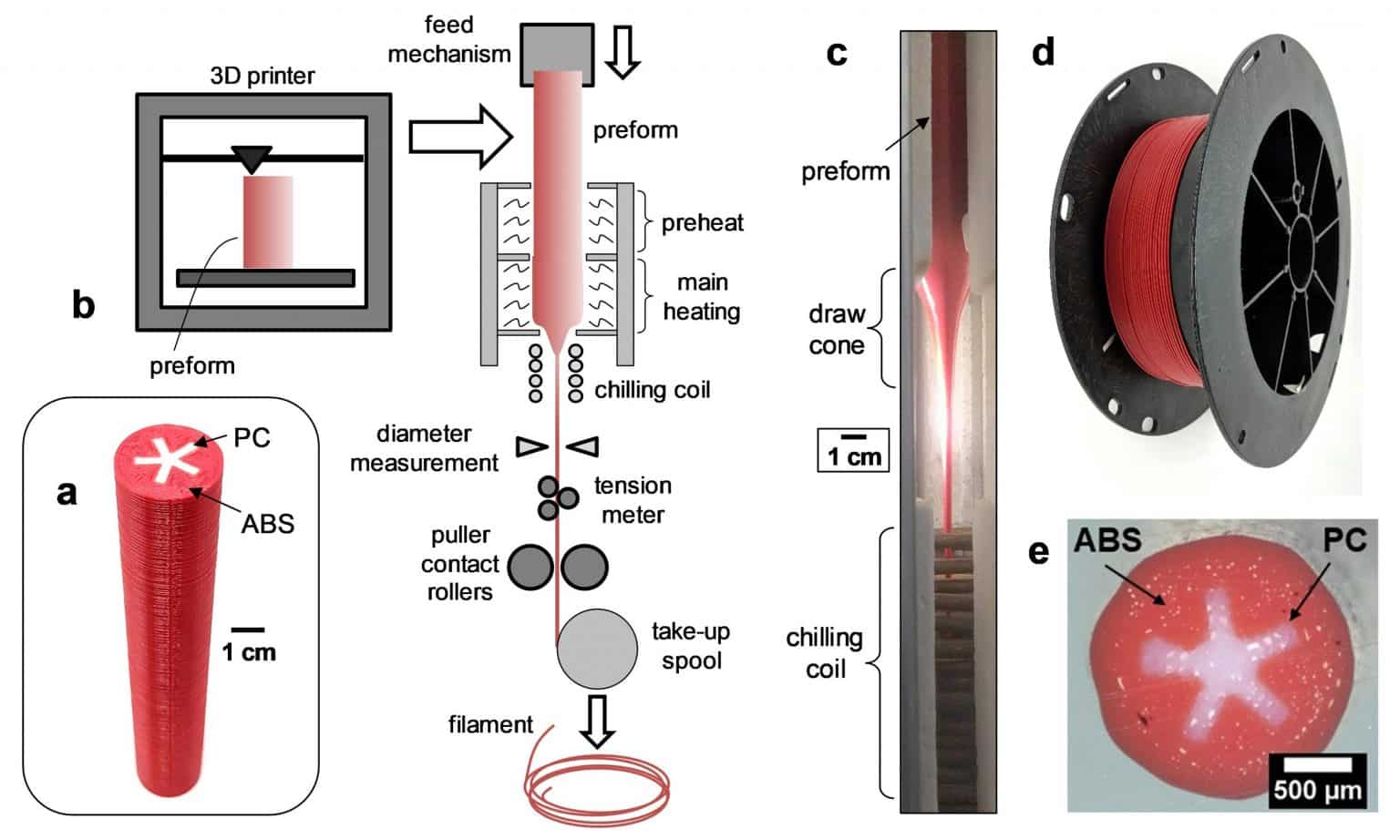

The research team used a novel hot drawing process to fabricate dual-material filament that contains a star-shaped polycarbonate core made of acrylonitrile butadiene styrene, called ABS.

This bi-material filament was then used as a raw material in a conventional FFF printer to create a 3-D solid with a mesoscopic structure of composite ABS/polycarbonate core.

This new type of DM filament can revolutionize additive manufacturing technology, allowing low-cost printers to produce parts with mechanical properties that compete with injection-molded plastics, as described in this article.

In the ongoing experiment, the Army ’s research team is experimenting with new material pairings, printing conditions, and annealing schemes to further improve mechanical properties and reduce processing time. Their goal is to reduce the current 24-48 hour annealing time to 4 hours or less.

Researchers are using pilot production lines to produce more filaments in the next few months to provide material samples to various Army transition partners.

“Having the option to additively manufacture parts from a high strength polymer via the FFF process, at the field, division, and/or depot-level will certainly provide warfighters with the ability to produce better temporary parts much quicker – hours versus days or weeks – and at significantly lower costs – often pennies compared to tens of dollars, said Jeff Wallace, a mechanical engineer with the Army’s C5ISR Center at APG. “Additionally, Soldiers tend to improvise as needed, often finding their own design solutions to the issues they face. As such, offering them a higher strength polymer material that can be used in the desktop printers they have access to, affords them the opportunity to innovate on-the-fly, as necessary to temporarily solve greater numbers of supply and design challenges. Their designs would then be sent to the proper Engineering Support Activity for evaluation.”

The laboratory has filed multiple patent applications for the technology, and one aspect of the technology has been licensed: the use of specialty polymer hot-drawn filaments for additive manufacturing. The Army is looking for other commercial partners to accelerate the development and application of this technology, which may have broad applicability to a wide range of additively manufactured thermoplastic parts.