I was playing a game of Trivial Pursuit with my parents recently, and then there was a question, I was sure my husband would know the answer. So, who wants to be a millionaire style? For the show, I called my friend. He correctly answered the question of astronaut Edward Higgins White II, “Who said on the Gemini 4 Mission: ‘I don’t want to come back in’?” I knew he would do it right because he had already seen it. Many documentary series, titled When We Left Earth: The NASA Missions. This made me think about what kind of future space documentaries will explore. I hope that the answer will be a lot of 3D printing.

Additive manufacturing has changed the way we make engines and parts for rockets, the way we live on Mars or the moon a day, and new ways for astronauts to accept research and build necessary tools. KULR Technology Group Inc. announced this week that it has won a contract from NASA’s Marshall space flight. Things like optical components and cartilage have been printed or planned to be printed in outer space. Now we can add batteries to it. Central (MSFC) builds 3D printed battery systems for robotics and manned spaceflight applications.

The company is headquartered in San Diego, California, and creates, manufactures, and licenses next-generation carbon fiber thermal management technology for batteries and electronic systems. In fact, KULR recently announced that its flexible, compressible, high-performance, thermally conductive fiber optic thermal interface (FTI) carbon fiber material has received a US patent.

Dr. Timothy Knowles, co-founder and CTO of KULR, said: “The issuance of this patent continues to promote the development of our product research and development, thereby helping the battery pack to operate more efficiently.”

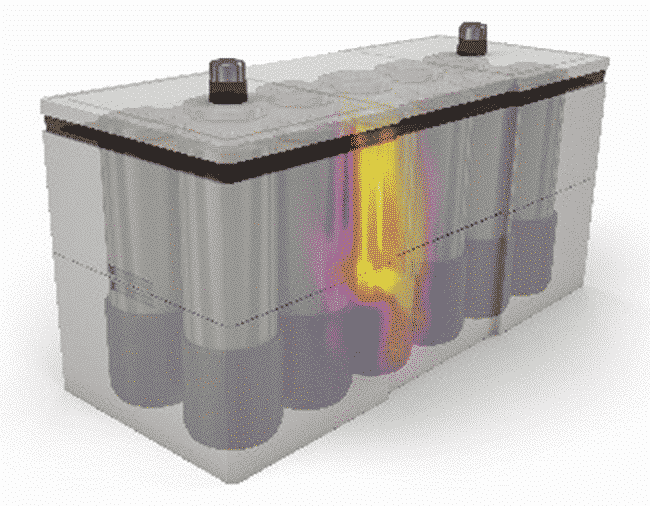

However, as part of the new dual-use technology development agreement, in order to develop a battery system that meets NASA JSC 20793 revision D safety standards for manned space missions, KULR will switch to its passive propagation immunity (PPR) and internal short circuit (ISC) Technology, the latter is exclusively licensed to KULR by NREL.

Matt Keyser, the manager of the vehicle electrification team responsible for the development of the battery ISC device, said: “With the battery ISC device, for the first time, we can trigger a battery failure at a known location and time.” “This vital research will now be in place. KULR continues to work to help battery manufacturers design new safety measures for battery systems.”

The patented, award-winning battery ISC device developed by NREL and NASA has completely changed the way we evaluate lithium-ion (Li-ion) batteries. Now, researchers can reliably simulate ISC and cause predictable lithium-ion battery cell failure, which can then be analyzed so that battery designers can learn how to adopt safety measures.

“Through our partnership with KULR, we will now have the incredible ability to build space-optimized battery pack systems in-orbit. We take the safety of our astronauts very seriously. KULR’s technologies will enable us to build safer battery packs that prevent dangerous thermal runaway propagation and protect our most valuable assets,” stated Human Landing System Cross Program Analysis Coordinator Brandon Lewis.

Last year, Fortune 500 companies Leidos and KULR joined hands with NASA to use PPR technology to efficiently transport and store batteries on the International Space Station (ISS).

“KULR’s thermal management technology should have applicability beyond this one implementation, both on the ISS and future destinations. Thermal management solutions are crucial to the safety and security of all missions, and we are pleased to see another effective use of KULR’s technology,” said Daniel Barineau, Senior Project Manager for Leidos.

Above, you can see what happens when a lithium-ion battery explodes in one of the company’s safety bags (spoiler alert: nothing, this is fine). Now, by combining MSFC’s 3D printing expertise with KURL’s proven PPR battery pack and ISC technology, astronauts should be able to easily know that the battery power system they print in space is safe.

“NASA employs highly rigorous assurance and safety standards, especially for our man-rated technologies. KULR’s PPR design solution for future manned and unmanned space missions is an ideal fit for mass design, flexibility, and cost, all the while maintaining this safety rigor through battery risks such as thermal runaway,” stated NASA MSFC Deputy Chief Technologist John Carr.

KULR says that 3D printing in space reduces the cost of human space exploration, leading to longer missions. In addition, the technology can also reduce the number of goods reserved for valuables and equipment-if it can be 3D printed in space, there is no need to transport goods from the earth.

“The optionality to repair and replace battery packs in space with parts 3D printed in space is a complete game changer. 3D printing of KULR’s PPR battery design will help lower the costs associated with battery pack transportation for the upcoming Artemis missions, where NASA will build sustainable elements on and around the moon in preparation for an eventual human mission to Mars,” Dr. Knowles said.