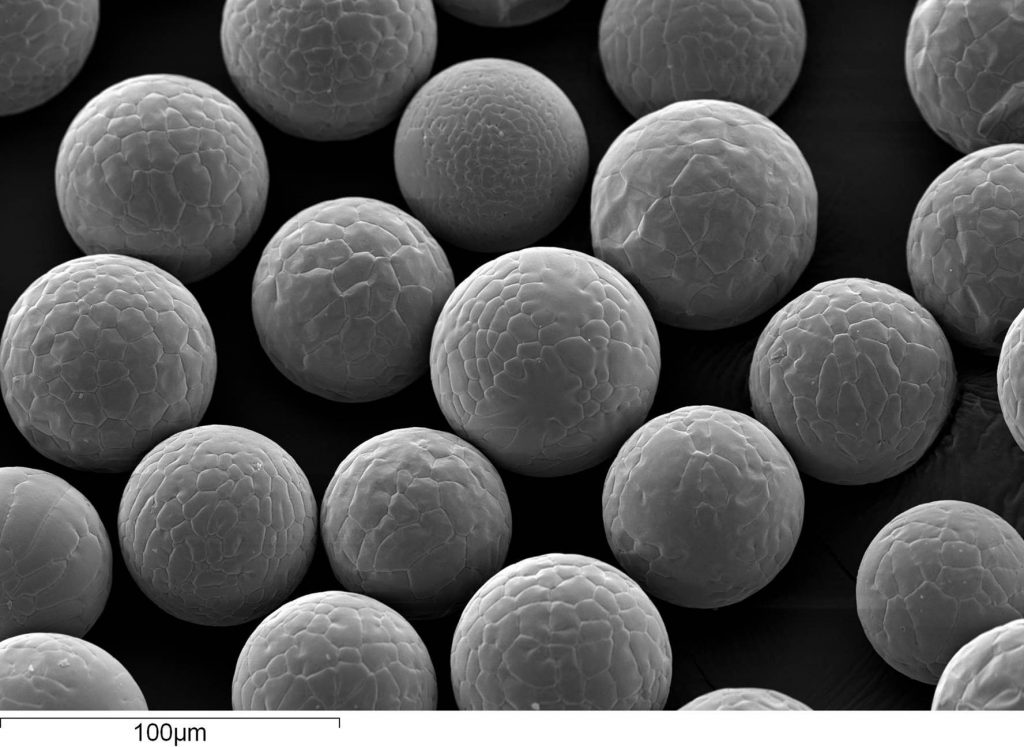

Equispheres, one of the metal AM materials companies that our sister company, 3dpbm Research, has been closely following for some time, just inked two important deals to advance the adoption and distribution of its innovative aluminum AM powders with Taiyo Nippon Sanso and Aconity. Regular readers will remember that we were the first media to offer a deep dive into Equispheres aluminum AM powders in our AM Focus 2020 eBook on Metal AM (article on page 43), as these materials first entered the market. Since then, Equisheres has been steadily growing, by offering specialized powder with unique attributes for additive manufacturing that can achieve 3x faster build rates than legacy aluminum powders.

Now the Canadian company formed a partnership with Taiyo Nippon Sanso Corporation (TNSC). The two organizations will work together to improve the economics and quality of additively manufactured parts in the Japanese market. Kevin Nicholds, CEO of Equispheres, said the Canadian company is excited to be working with TNSC. “Their expertise in metal additive manufacturing, company resources and deep connections to the Japanese market will accelerate the adoption of our material in the marketplace, with an emphasis on the automotive industry.”

TNSC is a Japanese-based, global provider of gases and related welding solutions at its AM Innovation Center. The company has developed a deep level of expertise in the technology and focuses on developing total solutions to improve reliability and reduce the cost of AM part production. TNSC has a partner network of metal AM industry leaders which will now include Equispheres.

Tadaharu Watanabe, Senior General Manager of Innovation Business Division (TNSC) stated, “We are very impressed with the quality of the Equispheres aluminum AM powder and view it as best-in-class for its ability to print high quality parts at a reduced cost. TNSC plans to offer the aluminum AM powder and our deep knowledge of its application along with our other integrated additive manufacturing services to better serve the AM industry in Japan.”

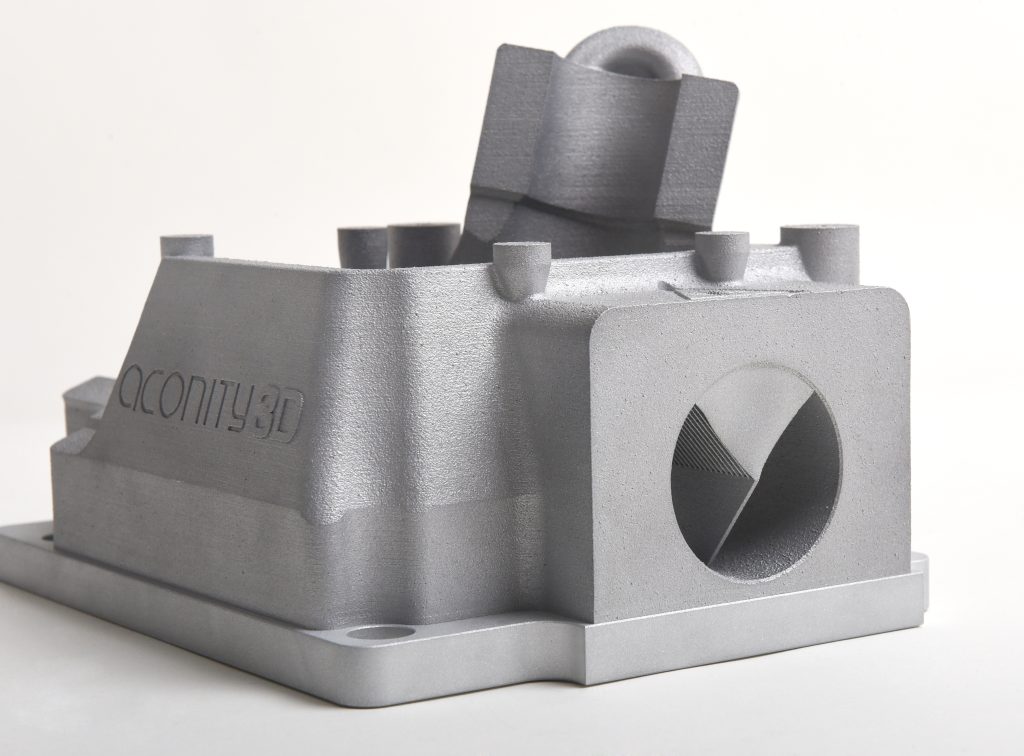

The second deal concerned Aconity, an innovative “modular” metal AM system manufacturer (featuring both powder bed and powder fed technologies), that will now distribute Equispheres feedstocks to its customers. The two companies had already partnered on R&D a few months ago.

Manufacturing on Demand

“Our material has proven to work well with Aconity3D equipment,” said Evan Butler-Jones, Vice-President – Product & Strategy at Equispheres.. “This non-exclusive agreement allows Aconity3D to provide its customers with a powder qualified on Aconity3D printing equipment, that has been shown to achieve higher build rates than traditional aluminum powders when combined with the precision and power of Aconity3D’s equipment.”

Aconity3D and Equispheres have achieved remarkable production speeds for 3D printing using the AconityTWO system and Equispheres’ specialized aluminum powders, which have unique attributes designed explicitly for AM. Equispheres aluminum AM powder is used to print the AconitySCAN, a key component of the Aconity3D line of printers. “We want our customers to have the best production experience when they utilize our specialized printer equipment. The best way to showcase our devices is to equip them with the best powder,” added Yves Hagedorn, Managing Director of Aconity3D.

“We are thrilled to build our partner network with a company of Aconity3D’s calibre,” Butler-Jones concurred. “They have a deep understanding of additive manufacturing and the skills, knowledge and equipment to push the boundaries of 3D printing of metal parts.”

According to the companies, the AconitySCAN can be printed 3x faster using Equispheres’ powder (i.e., 53 hours reduced to 17.5 hours) with no impact on mechanical properties. This dramatic reduction in production time reduces the cost to produce the part by greater than 50%. Such a notable productivity improvement will help advance metal additive manufacturing in cost-sensitive industries like automotive.

“This is a good example of how a high-precision printer and a high-performance powder can elevate additive manufacturing beyond conventional performance. Aconity3D has achieved fantastic results using our Performance line of powders, and now that same manufacturing advantage is available to any company embracing metal 3D printing.”

Butler-Jones explained that the spherical and uniform Equispheres aluminum AM powder can take advantage of both the precision and configurability of modern 3D printers. “Equispheres’ powder can absorb the energy from a powerful one-kilowatt laser without disturbing the stability of the melt pool. This is not attainable with standard aluminum powders, and it becomes more important as the industry embraces newer higher-tech printing equipment.”

Equispheres sells its powder directly in North America and Europe, backed by a strong Applications Engineering team. To serve the Japanese market, the company will leverage the distribution agreement with Taiyo Nippon Sanso Corporation (TNSC) mentioned above. The relationship between TNSC and Equispheres was established after a year-long analysis of Equispheres powder by TNSC. Both Equispheres and TNSC plan to collaborate on R&D projects to develop enhanced applications for the powder and provide further value to the industry.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment