One of the most exciting aspects of the technological world is how innovation can stack up with each other. Starting from basic computers, we gradually transitioned to more complex operating systems and touch screen technology, and as mobile phones gradually evolved into smartphones, we also turned to mobile phones. Since the first basic SLA 3D printer proposed by Chuck Hull in the 1980s, we have developed a wide variety of hardware, software, and materials that can be used by users worldwide.

Now that these technologies are brought together, the research team at the University of Bristol provides a new way to advance modern touch screens through 3D printing. Although many of us may have become accustomed to dealing with the same old style of interactive computer monitors due to stiff daily exercise (don’t forget how exciting this progress was when it was first launched!), the researchers from Bristol decided to push the limits of mediocrity with 3D touchscreens.

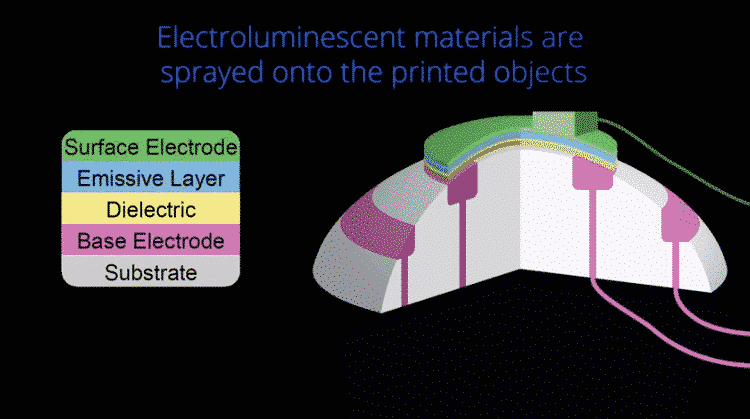

In collaboration with the MIT Media Lab, the team used a novel interactive display that was actually painted on the 3D printed parts (think of how graffiti artists work), and launched ProtoSpray. Dr. Anne Roudaut, associate professor of human-computer interaction at the University of Bristol, who is in charge of research, expects that they will continue this project by designing a machine that provides all-in-one production technology for 3D printing and painting.

“We have liberated displays from their 2D rectangular casings by developing a process so people can build interactive objects of any shape. The process is very accessible: it allows end-users to create objects with conductive plastic and electroluminescent paint even if they don’t have expertise in these materials,” said Ollie Hanton, PhD student and lead author of the research, recently presented at the ACM Conference on Human Factors in Computing Systems (CHI).

To encourage users to expand their horizons using digital technology, Hanton and his team hope that ProtoSpray will attract other manufacturers, hobbyists, and researchers who interact with shapes more dynamically, regardless of whether the shape is flat, curved, angular, or more complex Geometric shapes.

“3D printers have enabled personal fabrication of objects but our work takes this even further to where we print not only plastic but also other materials that are essential for creating displays. Using 3D printing of plastics and spraying of materials that light up when electricity is applied, we can support makers to produce objects of all shapes that can display information and detect touch,” said Hanton. “Our vision is to make screen/display a fundamental expressive medium in the same way people currently use ink, paint, or clay.”