Cat Keycaps Made with DMLS Titanium 3D Printing, Brass Casting and Silver Electroplating

- SLA 3D Printed Transparent Jar Prototype with Clear Resin

- SLA 3D Printed Giant Monogram Basketball Model for a Co-Branding Campaign

Posted on 2021-06-09 in Consumer ┬Ę µČłĶ┤╣Õōü

Process 3D Print, Support Removal, Post Curing, Polish, Electroplate

Material Resin, Metal

Quantity 3 pcs

Price Range $100-1,000

Lead Time 9 workdays

Material Resin, Metal

Quantity 3 pcs

Price Range $100-1,000

Lead Time 9 workdays

Gallery

About Project

We have cooperated with some design studios and 3D-printed keycaps and keycap prototypes for them. Most of the keycaps are made with resin, which are lightweight, cheap, but not durable. Only some high-end custom keycaps would involve using metal materials.

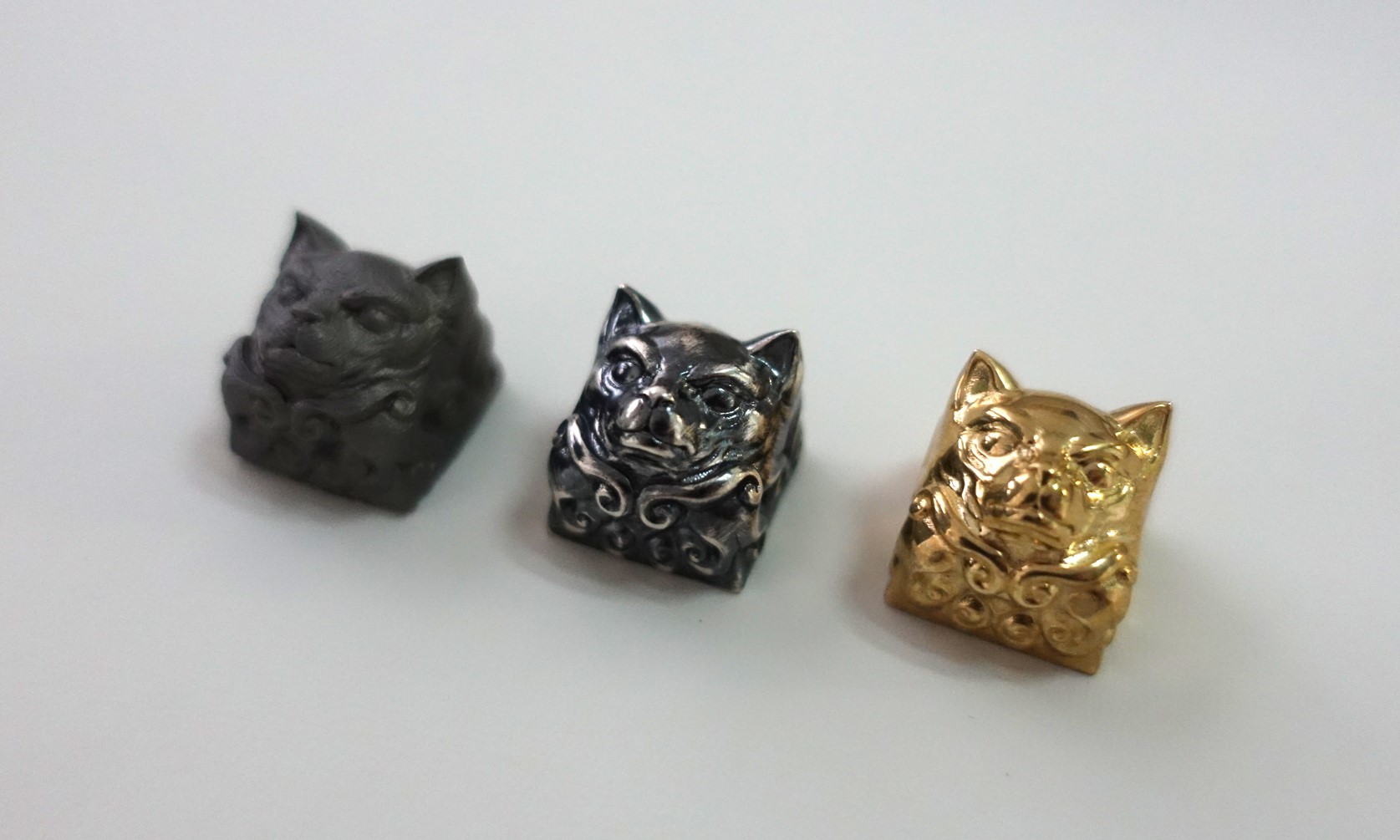

This time we 3D printed the cat head keycap with Titanium as a prototype. Then we 3D print the wax master pattern and cast two keycaps with brass, the finish of one is aged silver, and the other one is polished brass.

Solution

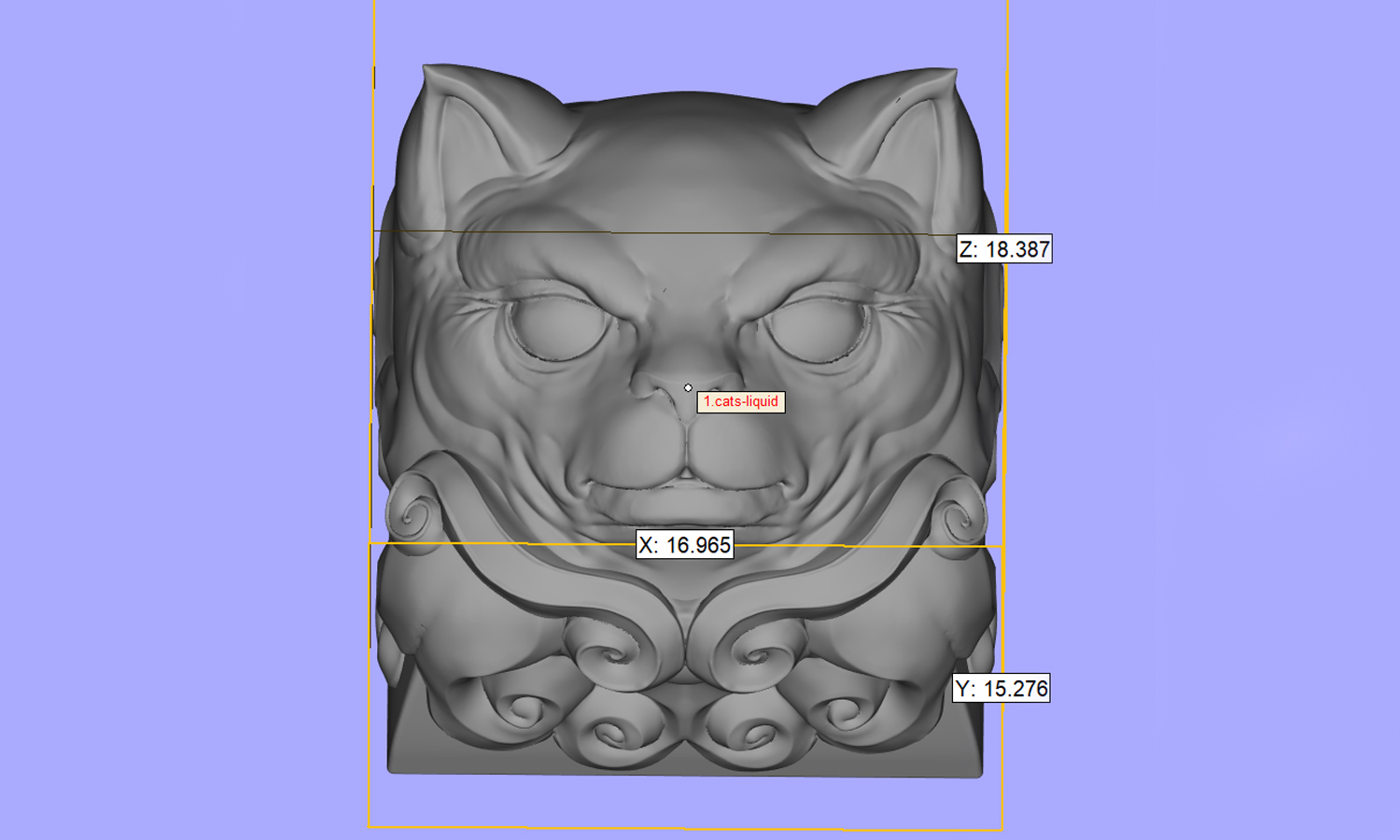

- Step 1: Examine the 3D model to make sure the structure and wall thickness does not need any revision. As the cat head is tiny and has rich details, it’s hard to polish and remove all the layer lines. Our engineer informs the client and shows him the polished and unpolished sample photos. The client accepts it and ordered a Titanium keycap without polishing.

- Step 2: Add supports to the model, prepare the titanium powders and preheat the printer chamber, then process printing with our metal 3D printer. The DMLS 3D printer automatically spread out one layer of powder after another, and the laser will systematically touch the correct spots of each layer and sinter the object together.

- Step 3: After printing finish, cool down the 3D printer and metal parts. Then comes the support removal. The photos show that there are obvious lines on the cat, flowing along its face, looking like its hair. The client is satisfied with the effect and ordered some more with casting technology.

- Step 4: 3D print the master pattern with Castable Wax and cast the brass keycaps with investment casting technique. As the wax print can be smoothened by IPA, the brass keycaps cast from the wax will also have a glossy surface, no layer lines. We electroplate one of the keycaps with silver and then distress it using boiled sulfur soap.