- SLA 3D Printed Construction Equipment Resin Scaled-down Models

- SLA 3D Printed Puzzle Wheel Toy Resin Prototype

Material Resin, Metal

Quantity 5 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

In the realm of modern manufacturing, precision and efficiency are paramount. The first photo showcases an impressive array of injection mold prototypes that embody these principles through the innovative use of conformal cooling designs. These prototypes highlight the synergy between advanced 3D printing techniques and thoughtful engineering, offering a glimpse into the future of mold making.

Visualizing Cooling Efficiency with SLA

On the left, we have a transparent plastic mold prototype. Created using the SLA (Stereolithography) 3D printing technique, this clear resin model provides an invaluable window into the internal structure of the mold.

- Clear View of Conformal Cooling: The visibility of the conformal cooling channels within the prototype is particularly noteworthy. These channels are meticulously designed to follow the contours of the mold cavity, ensuring uniform cooling throughout the molded part. This results in reduced cycle times and enhanced part quality by minimizing warping and internal stresses.

- A Vital Tool for Design Verification: The clear resin prototype serves as a vital tool for designers and engineers to verify the accuracy of their cooling channel designs before moving on to metal molds.

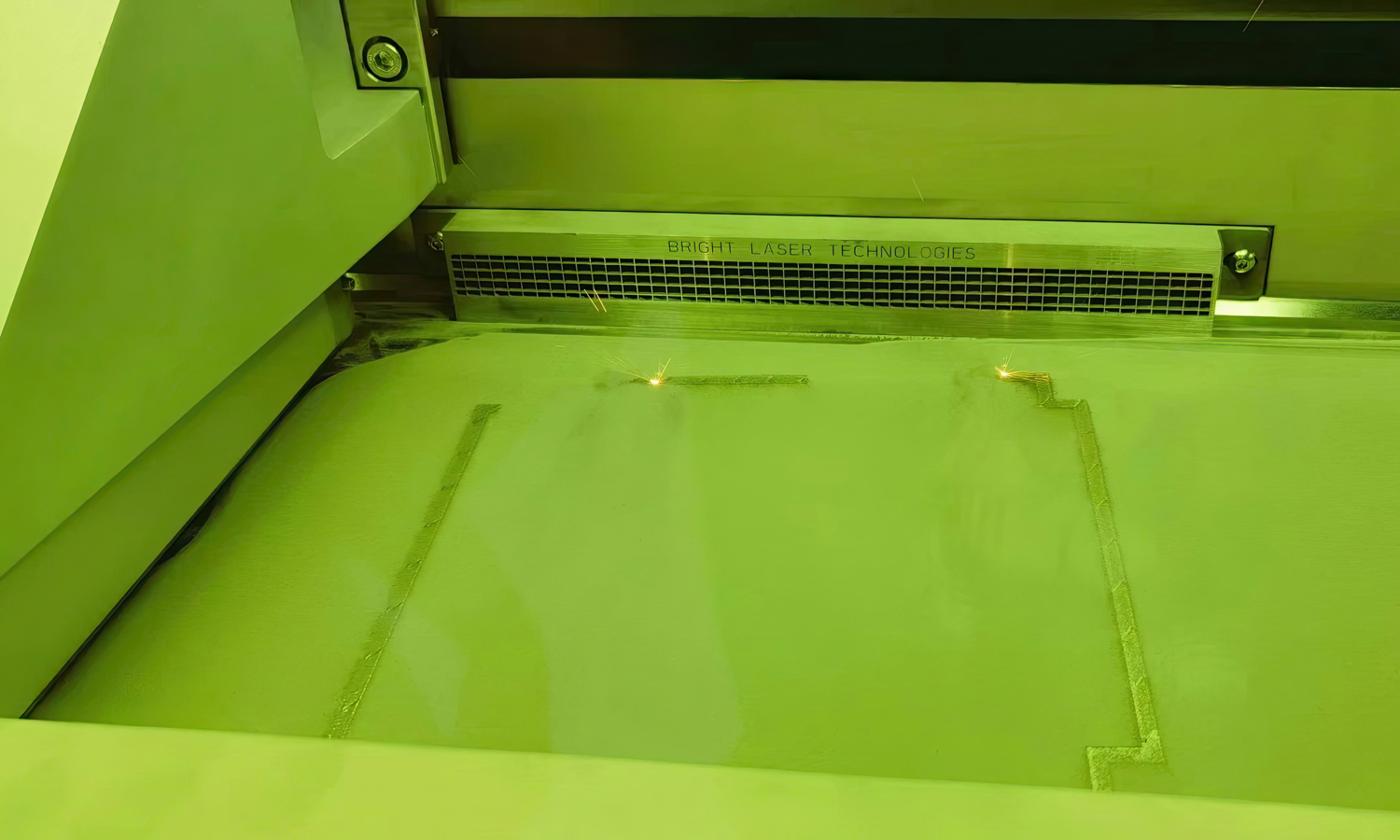

Precision and Durability with DMLS Metal Molds

The middle and right items are metal mold components, both crafted from SS316L stainless steel using Direct Metal Laser Sintering (DMLS) 3D printing techniques. These components are a testament to the precision and durability that DMLS offers.

- Integrated Conformal Cooling: The conformal cooling channels, though not visible from the outside, are integrated within these solid structures, following the complex geometries of the mold cavity. This ensures optimal thermal management during the injection molding process, leading to improved efficiency and part consistency.

- Intricate Design and Robustness: The right component features a protruding core, crucial for forming specific features in the final product. The middle component, with its machined surfaces and integrated cooling channels, exemplifies the intricate design capabilities enabled by DMLS technology. These metal prototypes not only demonstrate the effectiveness of conformal cooling designs but also highlight the robustness and accuracy of SS316L stainless steel in demanding manufacturing environments.

FacFox: Your Partner in 3D Printing Innovation

At FacFox, we understand the critical role that advanced manufacturing techniques play in modern production. Our state-of-the-art 3D printing services, including SLA and DMLS, allow us to deliver high-precision prototypes and final parts that meet the rigorous demands of today's industries.

- Unparalleled Accuracy and Efficiency: Whether you need clear resin prototypes to visualize internal structures or durable metal components with complex cooling channels, FacFox is equipped to bring your designs to life with unparalleled accuracy and efficiency.

- Transforming Ideas into Reality: Trust FacFox to be your partner in innovation, transforming your ideas into reality with our comprehensive 3D printing solutions.

Solution

- Step 1: A 3D model of the injection mold with conformal cooling channels was created using CAD software.

- Step 2: The 3D model was sliced into thin layers and converted into a format that can be read by the 3D printers.

- Step 3: The transparent prototype was printed using SLA 3D printing technology and SLA Clear Resin. A laser beam was used to cure the resin layer by layer according to the 3D model.

- Step 4: The transparent prototype was post-cured with UV, and then the supporting structures were removed with pliers. It was then sanded and polished with fine-grit sandpaper, sprayed with clear acrylic oil.

- Step 5: The stainless steel prototype was printed using DMLS 3D printing technology and SS316L. A laser beam was used to melt and fuse the metal powder layer by layer according to the 3D model.

- Step 6: The printed prototypes were removed from the build platform and cleaned of any excess material.

- Step 7: The transparent prototype was injected with yellow dye solution to make the conformal cooling channels more visible.

- Step 8: The stainless steel prototype was left with its raw grainy surface, and the layer lines on the bottom face were obvious without sanding and polishing.