Warning: Undefined variable $extension in /www/wwwroot/facfox.com/wp-content/themes/dante/functions.php on line 842

DMLS Stainless Steel 316LStainless Steel 316L A robust metal with a rough, pitted surface. Steel is available in a variety of polished and matte finishes, and good for a wide range of applications including jewelry, functional parts, and small sculptures. Max Build Size Min Build Size 3 û 3 û 3 mm Default Layer Height 0.04 mm Optional Layer Heights 0.05 mm Tolerance ôÝ 3% of any dimension (and one layer thickness of 0.1mm) N/A Smooth ã ã ã Detail ã ã ã ã Accuracy ã ã ã ã Rigidity ã ã ã ã ã Flexibility ã ã Available ColorsMetal

Available Post ProcessPolish

, Sandblast

, Electroplate

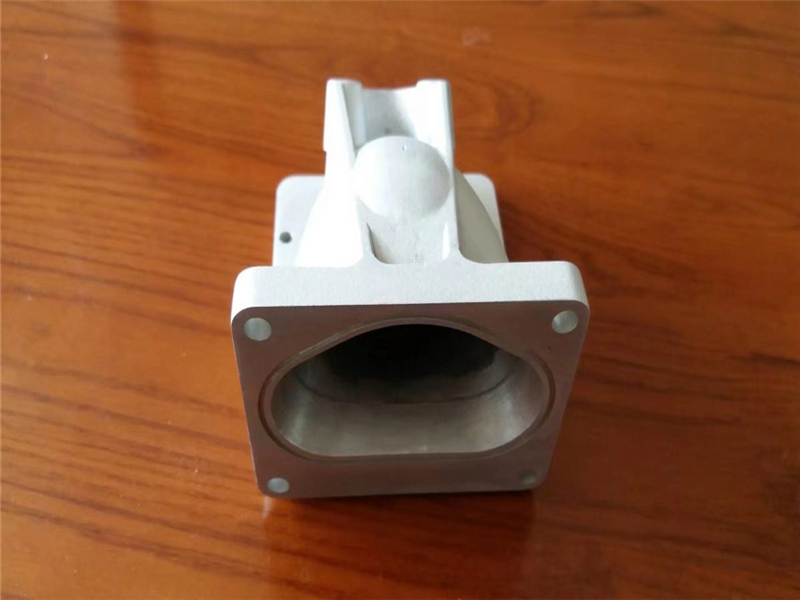

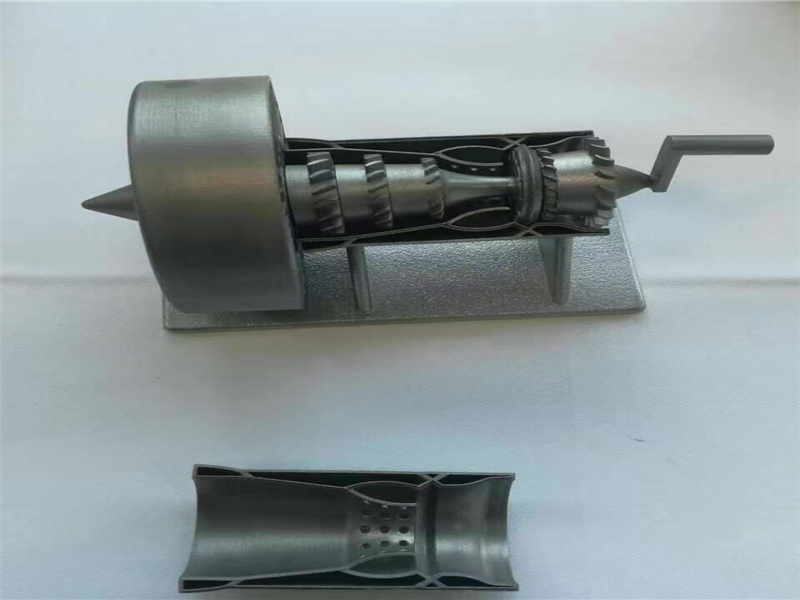

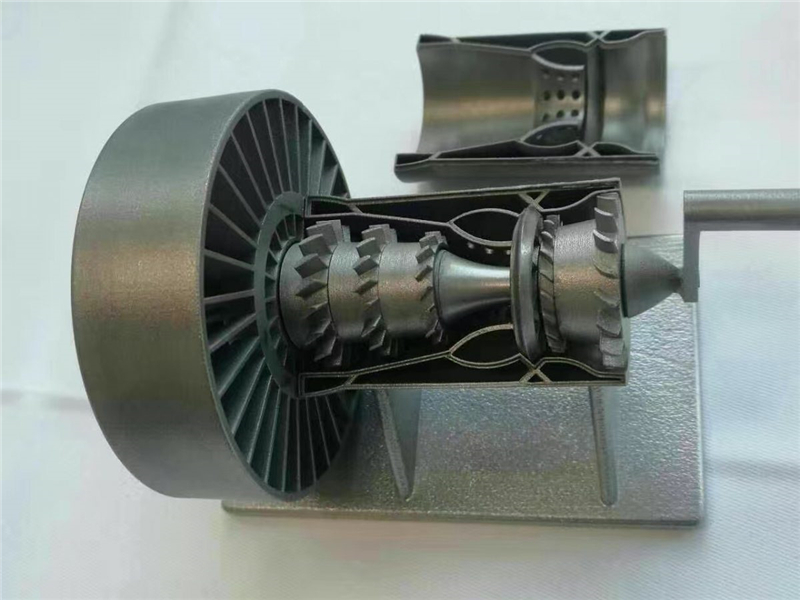

Suitable For Functional prototypes and end products, Not Suitable For Fine-detail models with smooth surfaces, Additional InfoAbout Stainless Steel 316L With no particular finishing, the material gives off a granular and coarse appearance, though suiting most applications. Smooth and shiny surfaces can be acquired after printing through finishing steps. Pieces can be machined, drilled, welded, electro-eroded, granulated, polished, and coated. Benefits and Main Uses Since the stainless steel is melded at a very high temperature, the additive metallic production process requires vast technical mastery for initial studying of thermal and mechanical effects before 3D printing. It also requires excellent knowledge of finishing techniques for the object’s completion. To ensure successful production of your piece, having to modify your initial design is commonplace. Even if we must be repetitive, we prefer to warn you: if you wish to create a stainless steel piece just for curiosity, you risk being disappointed when confronting the necessary effort and cost of undertaking the project! 316L Stainless Steel is good material for printing both functional and spare parts in 3D. The material is easy to maintain because it attracts little dirt and the presence of chrome gives it the added benefit of never rusting. 316L Stainless Steel is used to offer solid pieces and essential hygienics in several industries such as the medical, aeronautical, automobile, and domestic products industries.

Feature

3D PrinterMaterial Spec Sheet

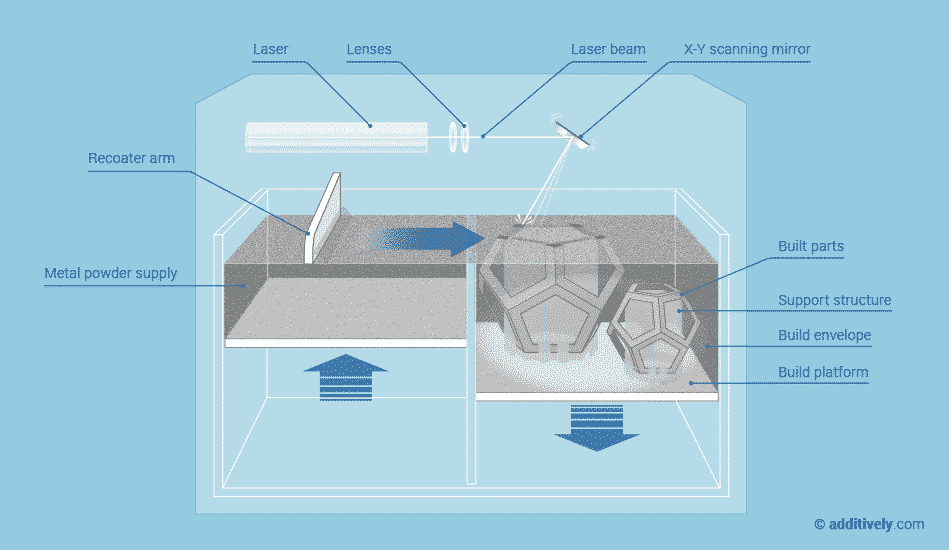

Selective Laser Melting creates objects from thin layers of powdered material by selectively melting it using a high power laser. The process takes place in a low oxygen environment in order to reduce thermal stresses and to prevent warping. Industrial metals are best used for high-tech, low-volume use cases from prototyping to creating end-use parts. Metal 3D prints are comparable to traditionally manufactured parts in terms of chemical composition, mechanical properties (static and fatigue) as well as microstructure. Once the printing is done, the extra powder that was not bound, and is not part of your design, is removed. Your part is now solid metal, and after the flutes are manually removed, it is tumbled and polished to produce a smooth finish.

|