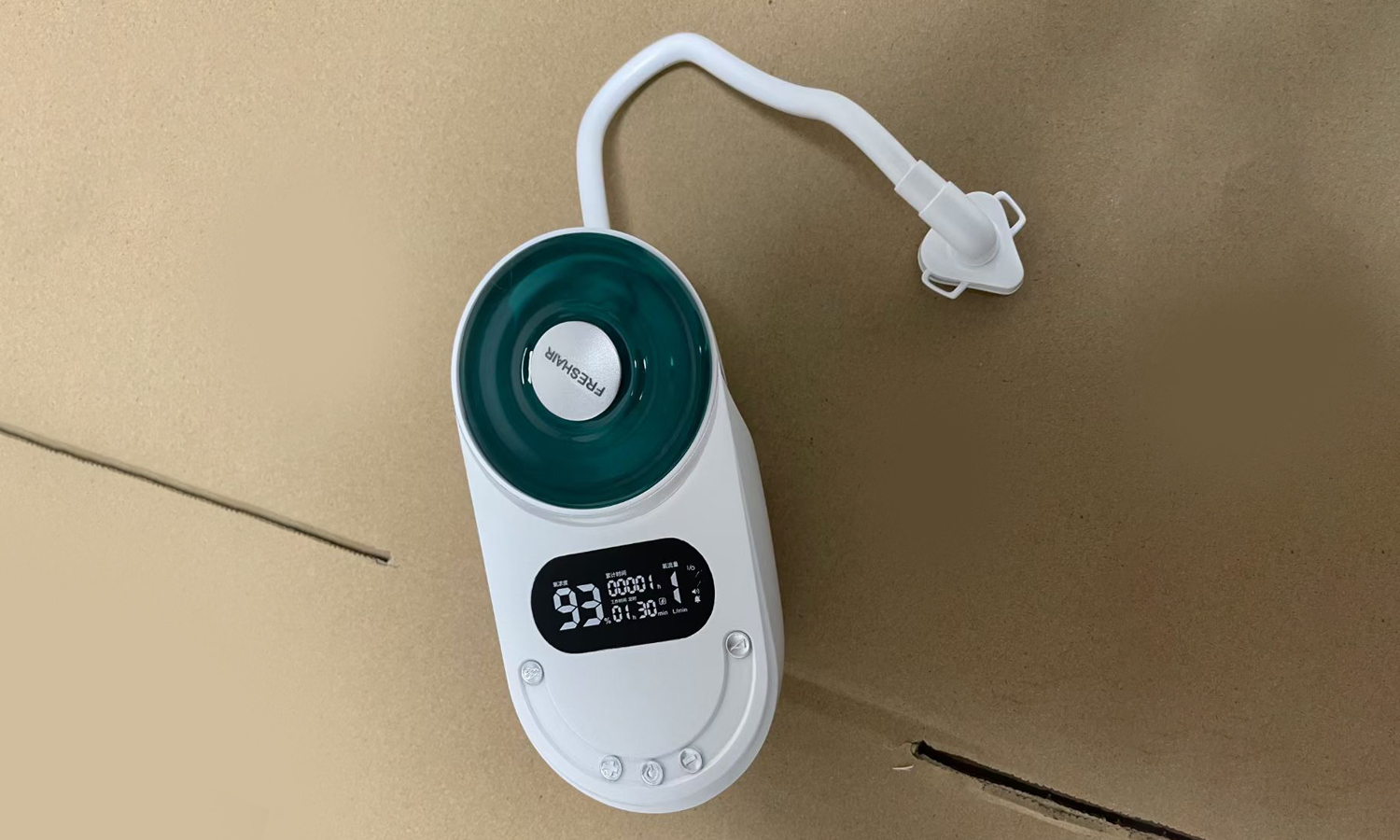

SLA 3D Printed Compact Oxygen Concentrator Resin Prototype

- SLA 3D Printed and Hand Polished Resin Assembly Parts

- SLA 3D Printed Electric Motorbike Scaled-down Resin Prototype

Posted on 2022-08-01 in Medical В· еҢ»з–—

Process 3D Print, Support Removal, Post Curing, Primer Coating, Polish, Paint, Glueing

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 6 workdays

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 6 workdays

Gallery

About Project

Oxygen concentrators take in air from the room and filter out nitrogen. The process provides the higher amounts of oxygen needed for oxygen therapy. The client aimed to develop a small and portable version. Here is a 3D printed prototype.

Solution

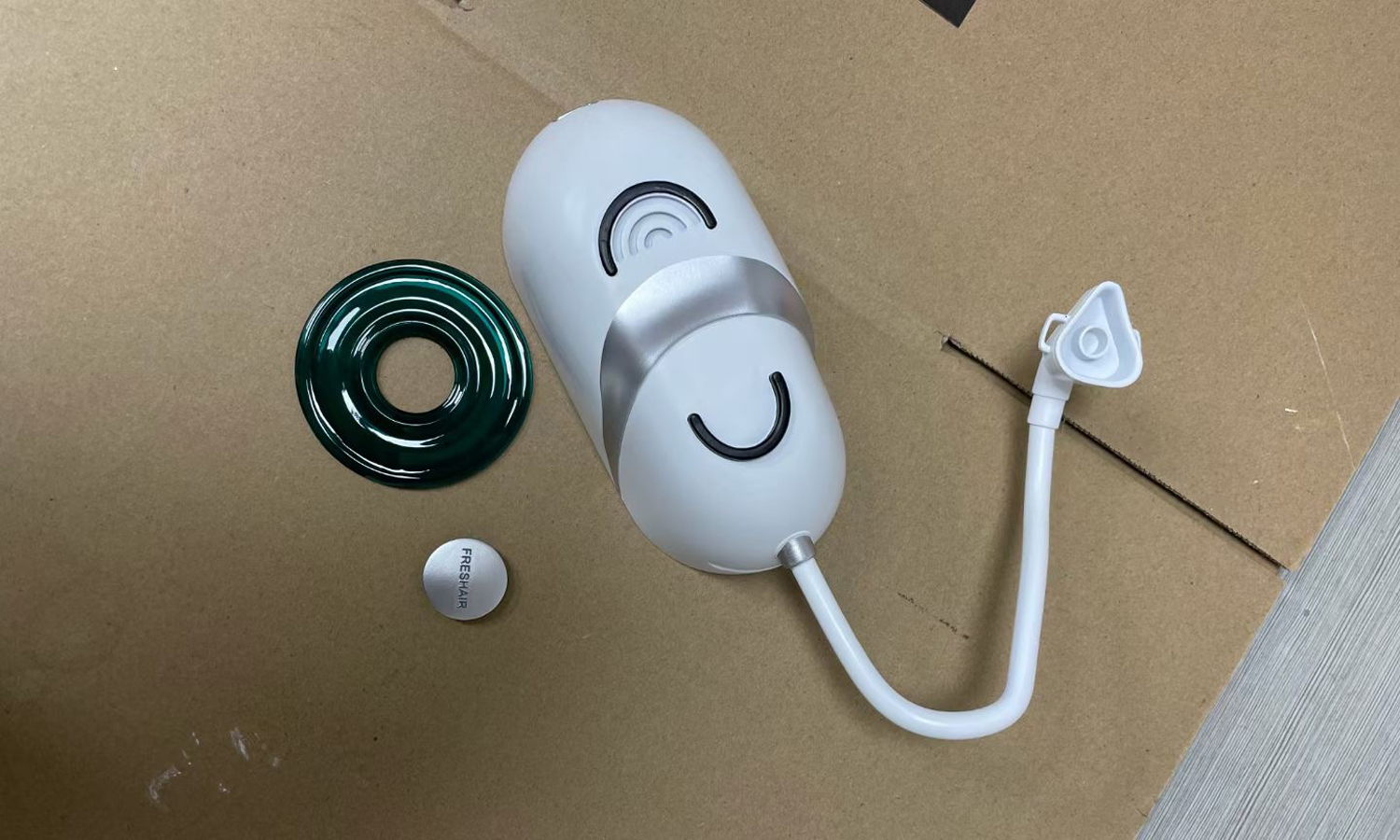

- Step 1: The client builds the model in CAD, and exports the STL files for printing. Our engineer would help him examine the model and split it into two parts for the convenience of printing and painting.

- Step 2: We arrange the main body, a round button and a circular faceplate in software and add necessary supports. Then 3D print them with SLA Generic Resin and SLA Clear Resin. The layer thickness we set is 0.05mm and we control the tolerance within Вұ0.1 mm.

- Step 3: When printing is completed, rinse the models with IPA and post-cure them with UV. Cut off all the supports and marks with scissors and graters, then polish with sandpaper. Try to assemble all the parts.

- Step 4: Rinse the clear window faceplate with dark green paint, and spary with clear acrylic oil. Paint the mainbody into white and silver with an airbrush and wool brush. Finally, assemble them together into one piece.