- SLS 3D Printed Nylon Electronic Device Case with Sealing Threads

- CNC Milled Aluminum Alloy Wireless Earbud PCB Holder

Material Resin

Quantity 50 pcs

Price Range $1,000-5,000

Lead Time 22 workdays

Gallery

About Project

FacFox is proud to showcase our advanced 3D printing capabilities in the medical field, particularly in supporting Percutaneous Coronary Intervention (PCI) procedures. We recently partnered with Wuhan Asia Heart Hospital to provide them with 50 SLA 3D printed anatomical heart models specifically designed to enhance PCI treatment demonstration and education.

Understanding PCI:

PCI is a minimally invasive procedure used to open blocked coronary arteries, the vessels that supply blood to the heart muscle. During PCI, a thin tube with a balloon or stent (a tiny expandable mesh tube) is inserted into a blocked artery. The balloon is inflated, widening the artery, and the stent may be placed to help keep the artery open.

The Role of FacFox's 3D-Printed Heart Models:

These detailed models serve two key functions in supporting PCI treatment:

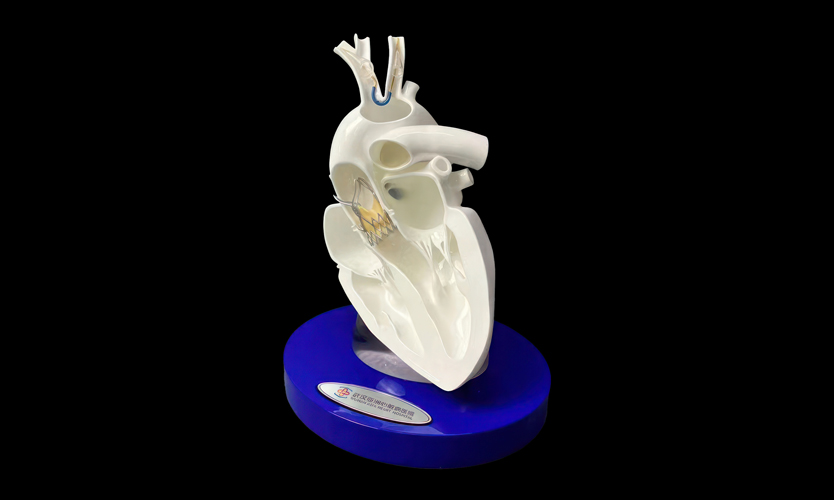

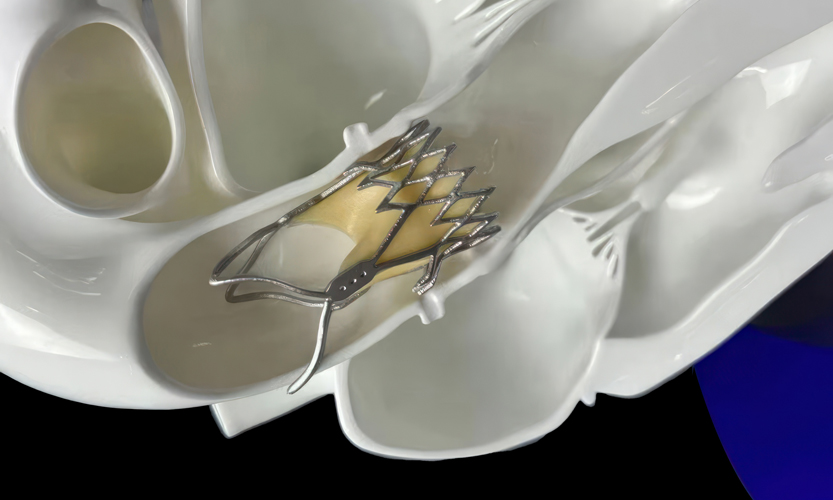

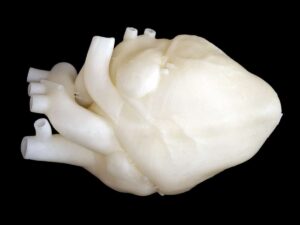

- Enhanced Patient Education and Demonstration: The life-size heart models, meticulously crafted in white resin, feature a realistic depiction of a human heart cut in half. This allows medical professionals to clearly illustrate internal structures, particularly the blood vessels. A crucial element of the model is a short vessel segment, printed in high-flexibility yellow resin, which simulates a real blood vessel. Surrounding this vessel is a silver stent, precisely 3D printed using DMLS technology with SS304 stainless steel. By visualizing the stent placement within the vessel, doctors can effectively demonstrate the PCI procedure to patients, improving understanding and reducing anxiety.

- Improved Surgical Planning and Training: The detailed and realistic models can be used by surgeons to plan complex PCI procedures beforehand. Studying the specific anatomy of a patient's heart, including any blockages, allows for a more targeted and efficient approach during surgery. Additionally, these models can be valuable training tools for medical professionals to practice PCI techniques in a simulated environment.

Beyond functionality, the models are presented with a touch of elegance:

- A crystal hemisphere, printed with clear resin, provides a base for the heart model.

- A deep blue colored resin base further enhances the visual appeal.

- To personalize the models, we incorporated a nameplate for Wuhan Asia Heart Hospital, making them ideal commemorative gifts.

This project highlights the versatility and precision of our SLA 3D printing technology. We can produce not only intricate anatomical models with exceptional detail, but also integrate multiple materials with varying properties. In this case, the combination of rigid and flexible resins alongside DMLS metal creates a model that is both visually informative and functionally realistic.

Beyond anatomical hearts, FacFox offers a comprehensive range of 3D printing solutions for the medical industry, including:

- Transparent implantable replacement heart models

- Surgical planning models of various organs

- Customized prosthetics and implants

FacFox is committed to partnering with medical professionals to advance patient care through cutting-edge 3D printing technology. Contact us today to discuss your specific needs and explore how FacFox can revolutionize your medical practice.

Solution

- Step 1: Design Preparation. The 3D digital models of the anatomical hearts were prepared using specialized software. The intricate details of the inner structure of the blood vessels were meticulously designed to ensure accuracy.

- Step 2: Material Selection. For the main structure of the heart, a white resin was chosen for its properties that resemble human tissue. A yellow flexible resin was selected for the short vessel to provide contrast, and stainless steel (ss304) was used for the silver stent.

- Step 3: Printing the Heart. The heart models were printed using Stereolithography (SLA) technology. The process involved curing the white resin layer by layer with a laser to build up the heart’s shape.

- Step 4: Vessel and Stent Fabrication. The short vessel was printed in yellow flexible resin to highlight its presence. Concurrently, the silver stent was produced using Direct Metal Laser Sintering (DMLS) to create a precise and durable structure.

- Step 5: Assembly. Once printed, the stent was carefully inserted around the yellow vessel. The heart was then positioned on a crystal hemisphere base, which was printed in clear resin to give the appearance of a delicate and transparent support.

- Step 6: Base Creation. A resin round cake was printed and painted in deep blue colors to serve as the foundation of the model. The nameplate of the hospital was affixed to the base to denote ownership and origin.

- Step 7: Final Touches. The assembled heart models were inspected for any imperfections and finished to achieve a high-quality presentation. The yellow vessel and silver stent were checked to ensure they were correctly placed and secured.

- Step 8: Packaging. The completed heart models were carefully packaged to prevent damage during transportation. Protective materials were used to cushion the models, ensuring they arrived in perfect condition.

- Step 9: Delivery. The packaged heart models were delivered to Wuhan Asia Heart Hospital, ready to be used as both gifts and demonstration models for Percutaneous Coronary Intervention (PCI) treatment.