- SLA 3D Printed Anatomical Heart Model for PCI Treatment Demonstration

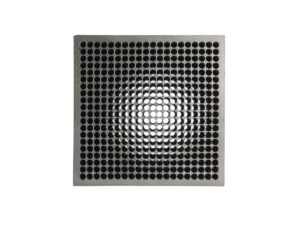

- SLM 3D Printed Stainless Steel Wireless Earbud PCB Holder

Gallery

About Project

Imagine crafting the perfect pair of wireless earbuds. Every detail is meticulously designed, from the sound quality to the sleek aesthetic. But there's one crucial component – the PCB holder that houses the delicate electronics. FacFox's CNC machining with aluminum alloy offers a solution that prioritizes both form and function.

CNC Machining: Precision Takes Center Stage for Earbud PCB Holders

CNC machining, or Computer Numerical Control machining, is a subtractive manufacturing process ideal for creating high-precision earbud PCB holders from aluminum alloy. Here's why it excels:

- Superior Surface Quality: CNC machining delivers an immaculate surface finish, unmatched by 3D printing methods. This translates to a visually stunning and professional-looking final product for your earbuds.

- Uncompromising Precision: CNC machining ensures exceptional precision for even the most intricate details. Round holes, square hollows, and small protrusions – all are flawlessly executed, guaranteeing a perfect fit for your PCB and seamless assembly.

- Design Flexibility: Similar to DMLS 3D printing, CNC machining allows for complex geometries and internal features. This flexibility empowers you to optimize the holder's design for functionality and weight distribution.

- Strength and Durability: Aluminum alloy offers a perfect balance between lightness and strength, making it ideal for everyday wear and tear without sacrificing weight.

FacFox: Your Partner in CNC Machined Electronics

FacFox is a frontrunner in CNC machining services for a vast array of electronic applications. Here's what makes us the perfect partner for your earbud project:

- Expert Design and Engineering: Our team collaborates closely with you to refine your earbud PCB holder design for flawless CNC machining.

- High-Quality Materials: We utilize only premium aluminum alloys to ensure the strength and longevity of your machined holders.

- Fast Turnarounds: FacFox prioritizes efficient production processes to deliver your earbud PCB holders quickly, without compromising quality.

- Cost-Effective Solutions: We offer competitive pricing for CNC machining services, making them a viable option for businesses of all sizes.

CNC Machining: The Ideal Choice for Prototype Perfection

For projects demanding exceptional precision, a smooth surface finish, and the ability to create complex geometries, CNC-machined aluminum alloy reigns supreme. FacFox's expertise in CNC machining allows you to bring your earbud PCB holder design to life, ensuring a flawless prototype that sets the stage for production success. Check this if you want to know more about the prototyping process of this earbud.

Contact FacFox today to discuss your earbud project and receive a quote for our CNC machining services. Let's create a PCB holder that elevates your earbuds in every way!

Solution

- Step 1: Design & 3D Modeling. The PCB holder was initially conceptualized and a 3D model was created using computer-aided design (CAD) software, ensuring all details were accurately represented.

- Step 2: Material Selection. A block of high-quality aluminum alloy was chosen for its excellent machinability and durability.

- Step 3: CNC Milling Setup. The aluminum block was then securely fixed onto the CNC milling machineŌĆÖs worktable.

- Step 4: Machining. The CNC machineŌĆÖs cutting tools were engaged, and the aluminum block was sculpted into the desired shape. The process was carefully monitored to maintain precision.

- Step 5: Detailing. Round holes and square hollows were cleanly milled, and small protrusions were formed on either side of the shell to serve as attachment points.

- Step 6: Inspection & Quality Control. The final product was inspected to ensure it met all specifications and quality standards.