- SLS 3D Printed Personalized Medals As Souvenirs In The Battle With Coronavirus

- SLS 3D Printed Nylon Abstract Wall Sculpture

Gallery

About Project

At the beginning of March, an overwhelmed hospital in Brescia, Italy raised the alarm that they were in lack of the breathing tubes. The respiratory valve is a kind of consumable accessory of the CPAP Hood System, which is essential for the life-saving coronavirus treatments.

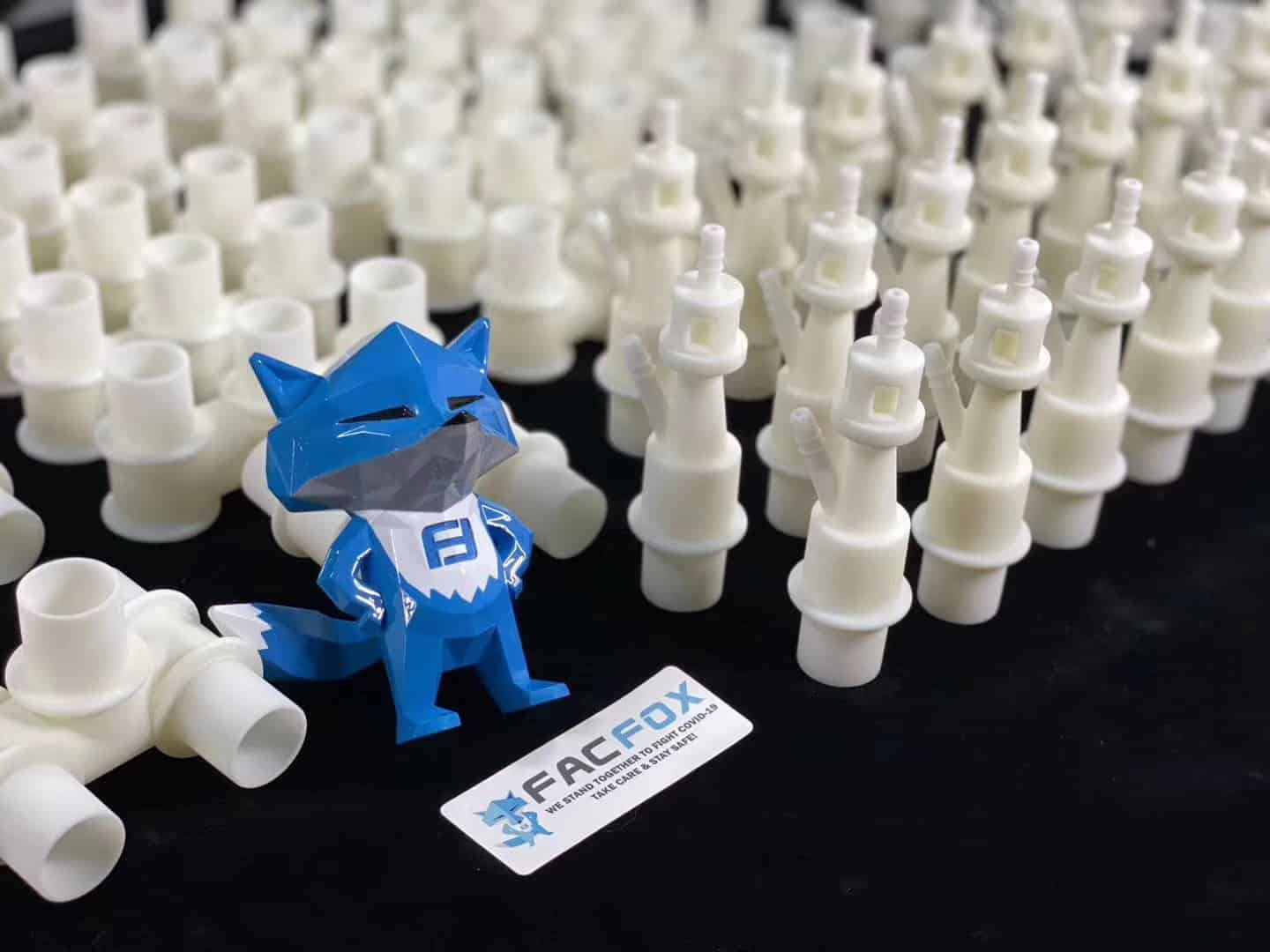

Words soon reached other 3D printing companies around the world and many were willing to lend a helping hand. Facfox has printed 30 packs of valves, 4 pieces in one pack, which are sent to Italy as a donation.

FacFox selects SLA Generic Resin and prints with Stereolithography(SLA) machine for the following reasons:

1. The SLA Generic Resin has a lower cost than SLS and MJF nylon.

2. Compared with FDM plastic and MJF, SLS nylon, SLA Generic Resin part has better airtightness and water tightness. FDM printed part has relatively large gaps between plastic layers, and nylon powder sintered structures also have tiny gaps. There is a risk that they will leak under high-pressure.

3. Compared with FDM, SLS, and MJF, the SLA printed part has a smoother surface and less dust. ItŌĆÖs also easy to be cleaned and installed.

4. After the resin is printed, there will be a UV post-curing process. That is to say, the printed part goes through sterilization during this procedure, thus the safeness and cleanness are further guaranteed.

Solution

- Step 1: 3D modeling.

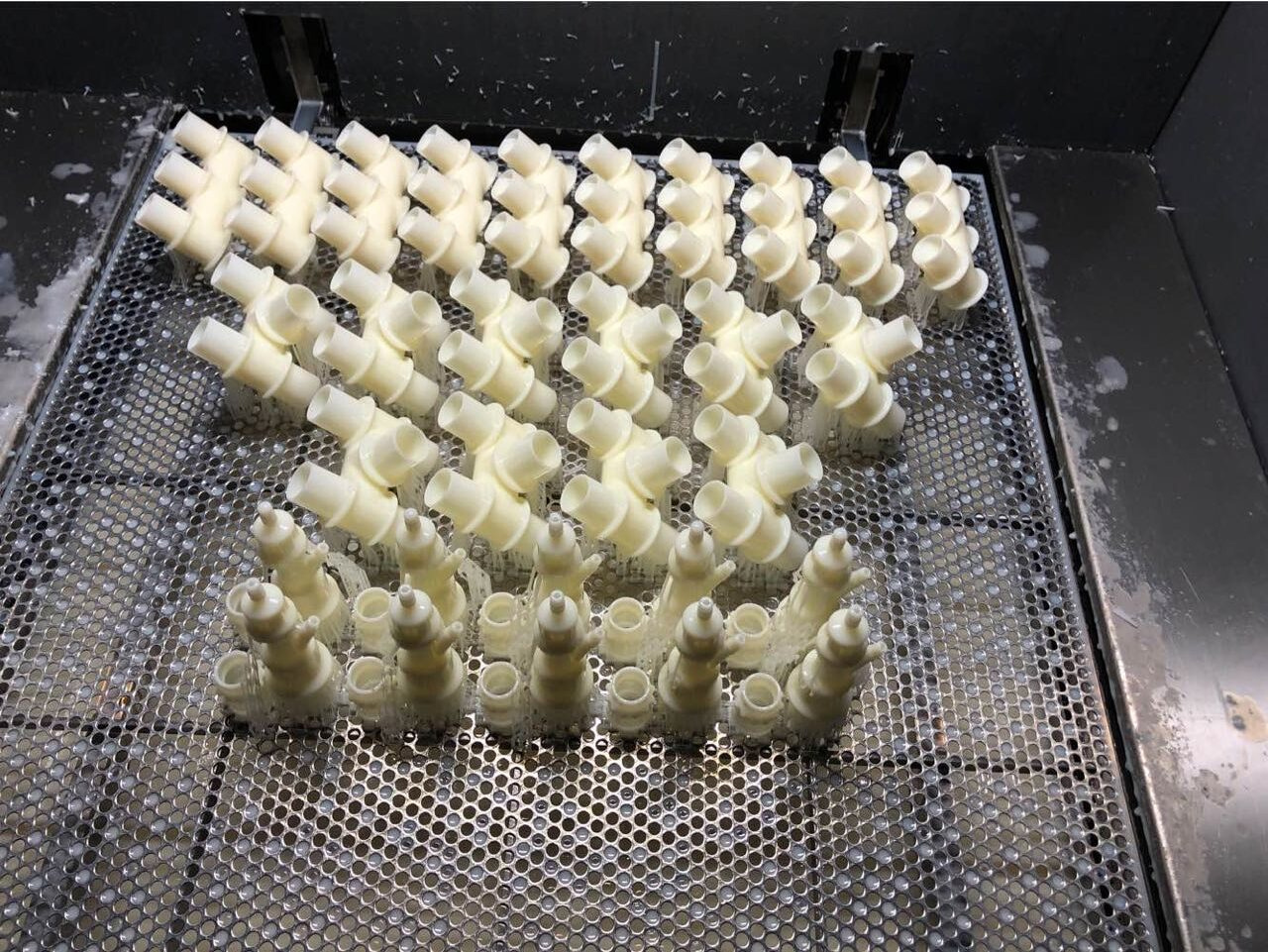

- Step 2: SLA 3D Printing the valves.

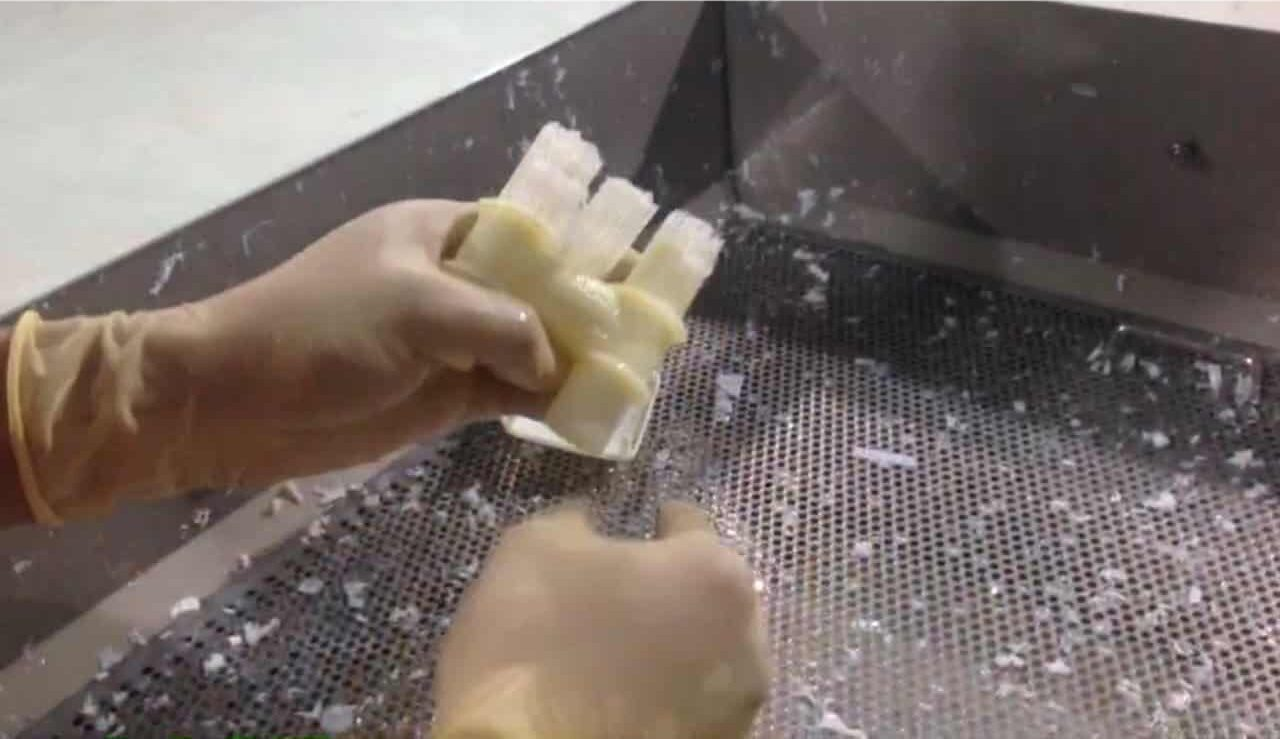

- Step 3: Support removal.

- Step 4: Remove the valves from the plate.

- Step 5: Clean and sand the surface of the printed valves.

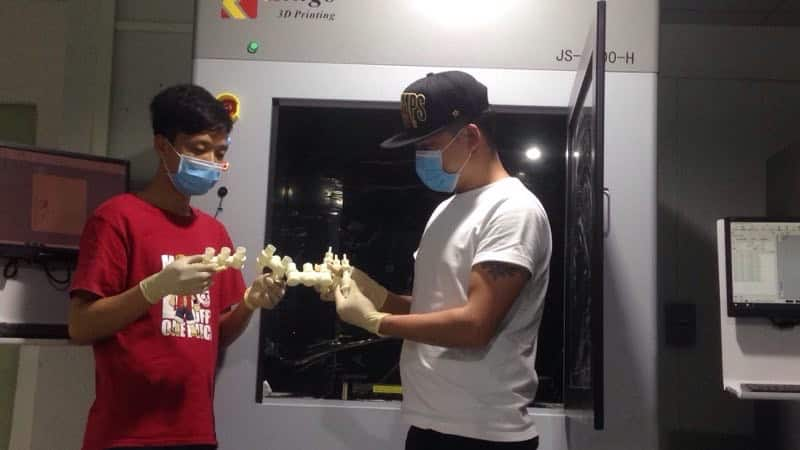

- Step 6: Inspection of the valves.