- SLA 3D Printed Clear Resin Cartoon Figure Dyed with Gradient Color

- CNC Machined SS316L Triangular Flange Nut

Gallery

About Project

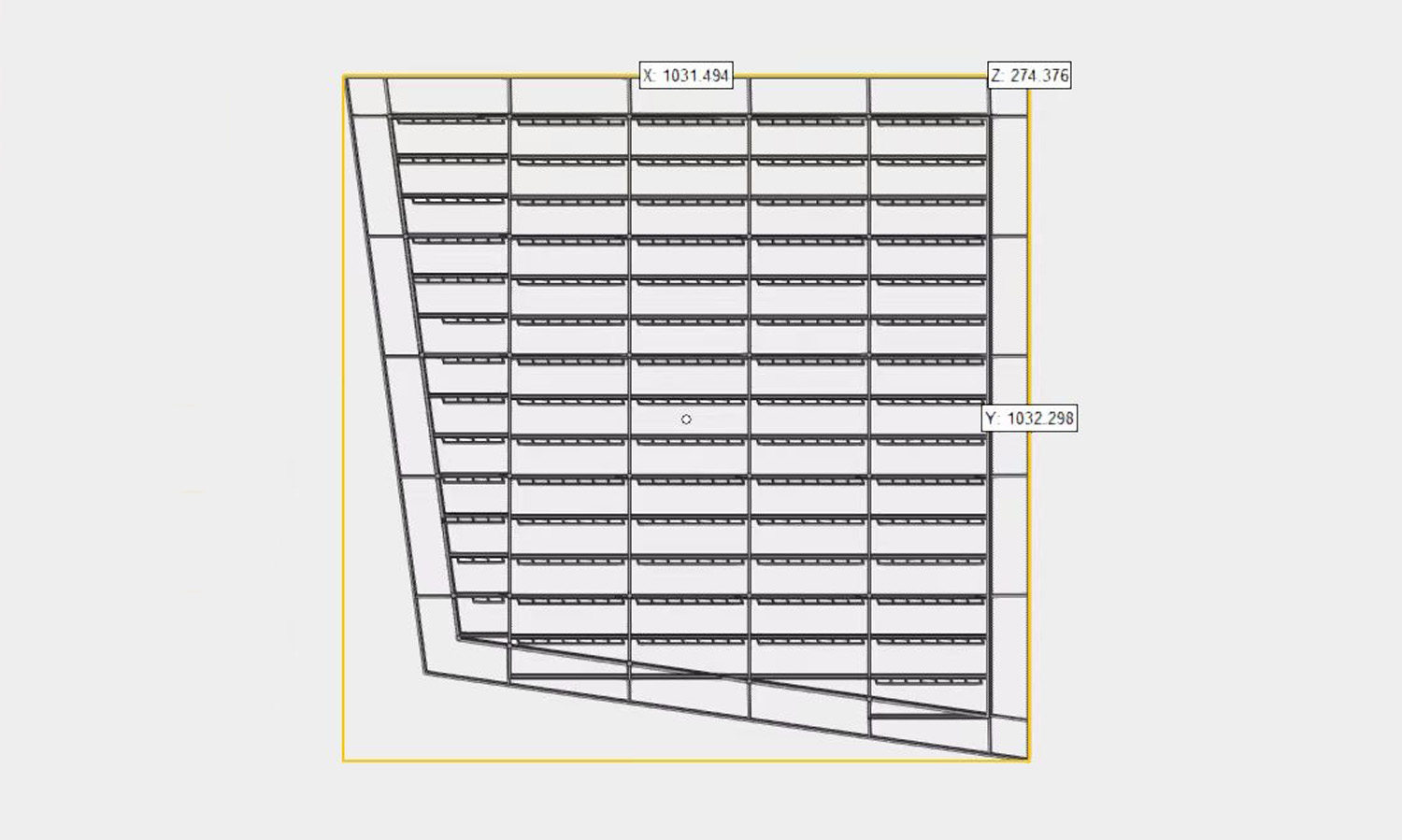

Need a large, flat rack with intricate details? Look no further than FacFox’s SLS 3D printing technology. We can handle even the most challenging designs, creating highly durable and functional prototypes or end-use parts.

Why SLS? Overcoming FDM Limitations

Traditional FDM printing can struggle with large, flat structures due to warping and deformation. At FacFox, we offer a superior solution: SLS 3D printing.

SLS 3D Printing: Power and Precision

SLS utilizes a high-powered laser to sinter layers of powdered nylon, resulting in exceptionally strong and dimensionally accurate parts – perfect for storage, organization, or specialized applications like aquarium fish tank bottom isolation boards.

Tackling Large, Delicate Prints: Our Secret Sauce

- Strategic Splitting: We strategically split your large model into sections, minimizing warping and enabling efficient printing.

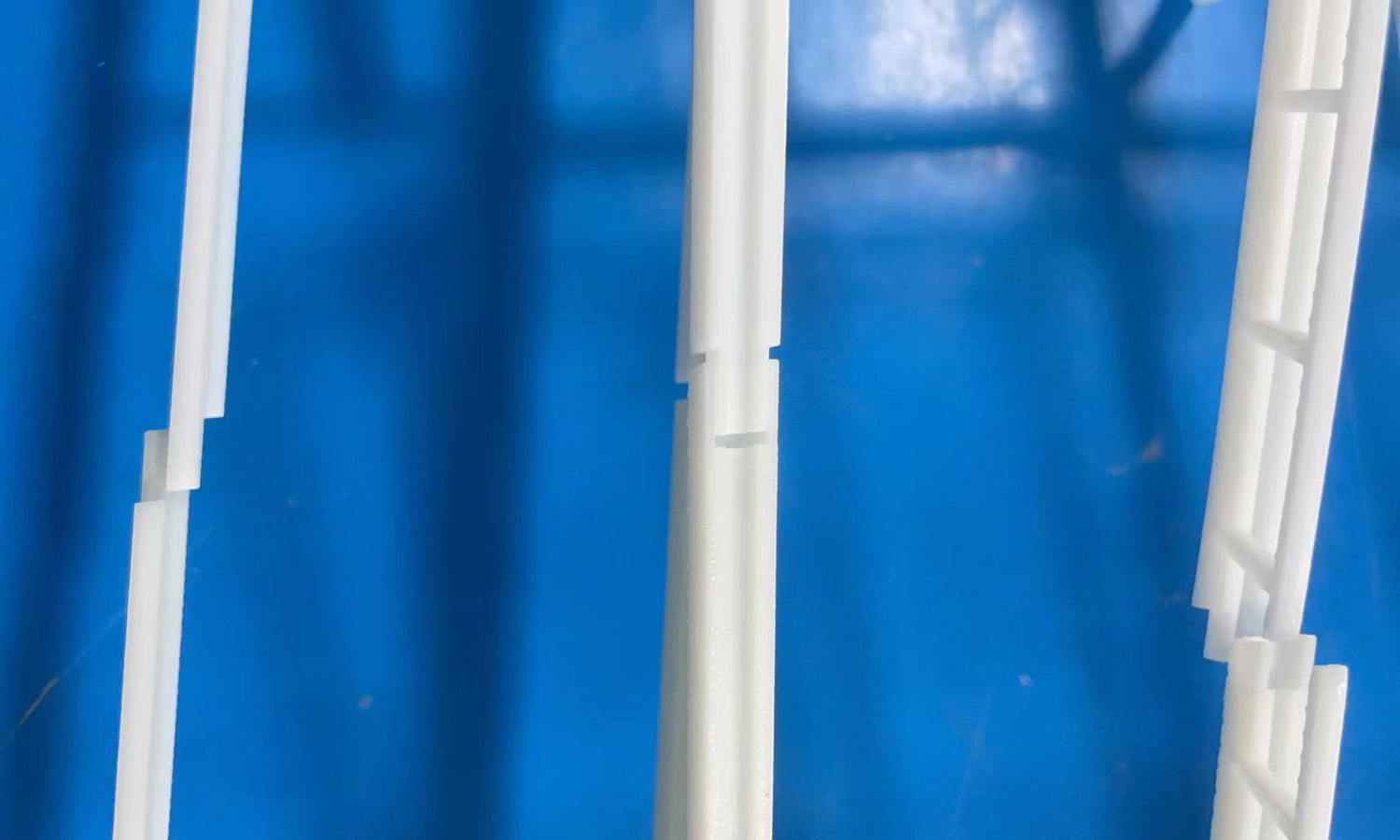

- Interlocking Design: Our team incorporates an interlocking mechanism for seamless assembly of separate parts into a robust final structure.

- Cost-Effective Splitting: Splitting the model also reduces transportation costs, a significant advantage for large prints.

Benefits of SLS 3D Printed Nylon Racks:

- Unmatched Strength and Durability: SLS nylon boasts superior mechanical properties, ideal for demanding applications.

- Dimensional Precision: SLS printing delivers precise parts with minimal tolerance deviations.

- Design Flexibility: Create intricate grid and bridge structures directly within the rack design.

- Cost-Effective Splitting: Smart splitting reduces both printing and transportation costs.

From storage racks to organizational tools and custom aquarium components, FacFox’s SLS 3D printing with interlocking design is the perfect solution. Contact us today to discuss your project and get a free quote!

Solution

- Step 1: The design was then exported in a 3D printable file format. The SLS printer was prepared, which involved preheating the powder bed to just below the melting point of the nylon material.

- Step 2: The printing process began with the application of a thin layer of nylon powder over the build platform. A high-power laser selectively sintered the powder, tracing the cross-section of the model to solidify the first layer. This step was repeated, with the platform lowering incrementally after each layer, until half of the rack was completed.

- Step 3: To prevent deformation due to the large size of the model, the rack was designed to be printed in two halves. Each half was printed separately with an interlocking mechanism. After printing, the two halves were left to cool down within the unsintered powder, which supported them during the process and eliminated the need for additional support structures.

- Step 4: Once cooled, the two halves were removed from the powder bed and cleaned of excess powder. The interlocking mechanism allowed the two halves to be combined seamlessly into one piece. This modular design facilitated not only the reduction of potential deformation but also minimized transportation costs due to the smaller package size required for each half.

- Step 5: The final product, potentially used for storage, organization, or as an aquarium fish tank bottom isolation board, showcased the versatility and efficiency of SLS 3D printing for creating large, complex parts with functional mechanisms.