SLS Rapid Prototyping Services

Industrial 3D printing process that produces functional nylon prototypes and end-use production parts in as fast as 1 day.

Make nylon parts starting at only $25!

Overview: How SLS 3D printing works?

The Basics Of SLS 3D Printing Services

Selective laser sintering (SLS) is an industrial 3D printing process that produces accurate prototypes and functional production parts in as fast as 1 day. Multiple nylon-based materials are available, which create highly durable final parts.

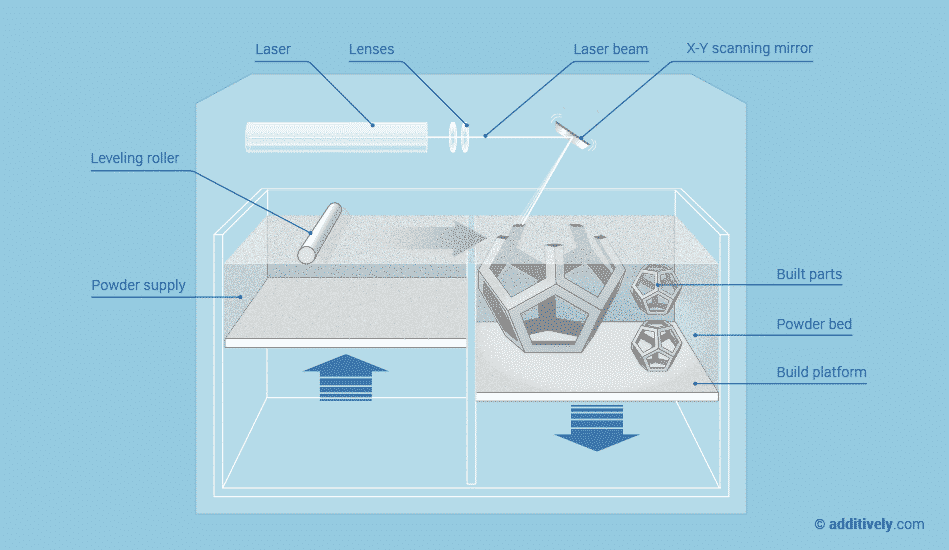

A thin layer of plastic powder is selectively melted by a laser. The parts are built up layer by layer in the powder bed.

A laser sintering machine will coat a layer of plastic powder onto a build platform, which is melted by a laser (or multiple lasers). The build platform will then be lowered and the next layer of plastic powder will be laid out on top. By repeating the process of laying out powder and melting where needed, the parts are built up in the powder bed.

When the build finishes, the entire powder bed with the encapsulated parts is moved into a breakout station, where it is raised up, and parts are broken out of the bed. An initial brushing is manually administered to remove a majority of loose powder. Parts are then bead blasted to remove any of the remaining residual powder before ultimately reaching the finishing department.

Benefits Of SLS 3D Printing Services

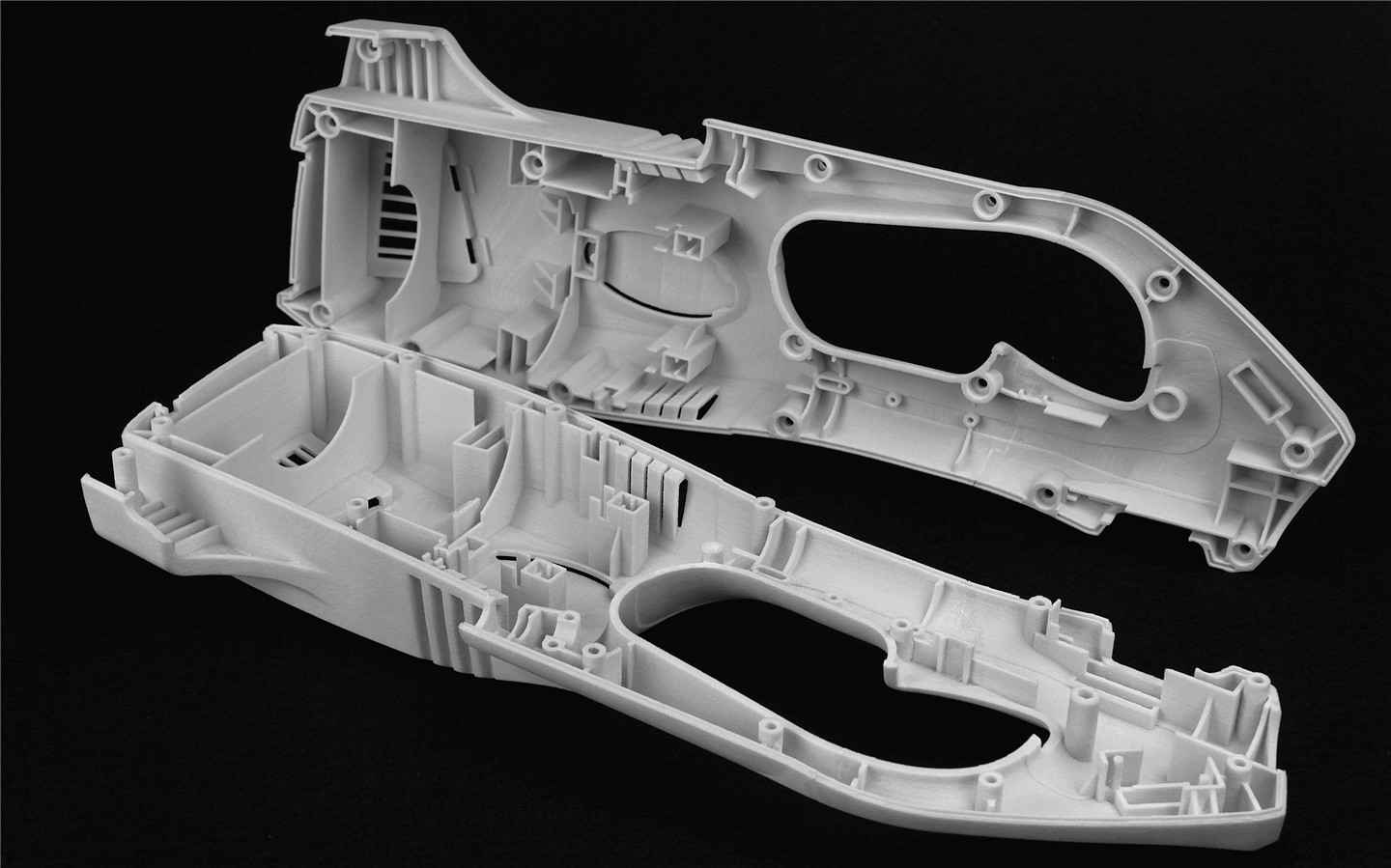

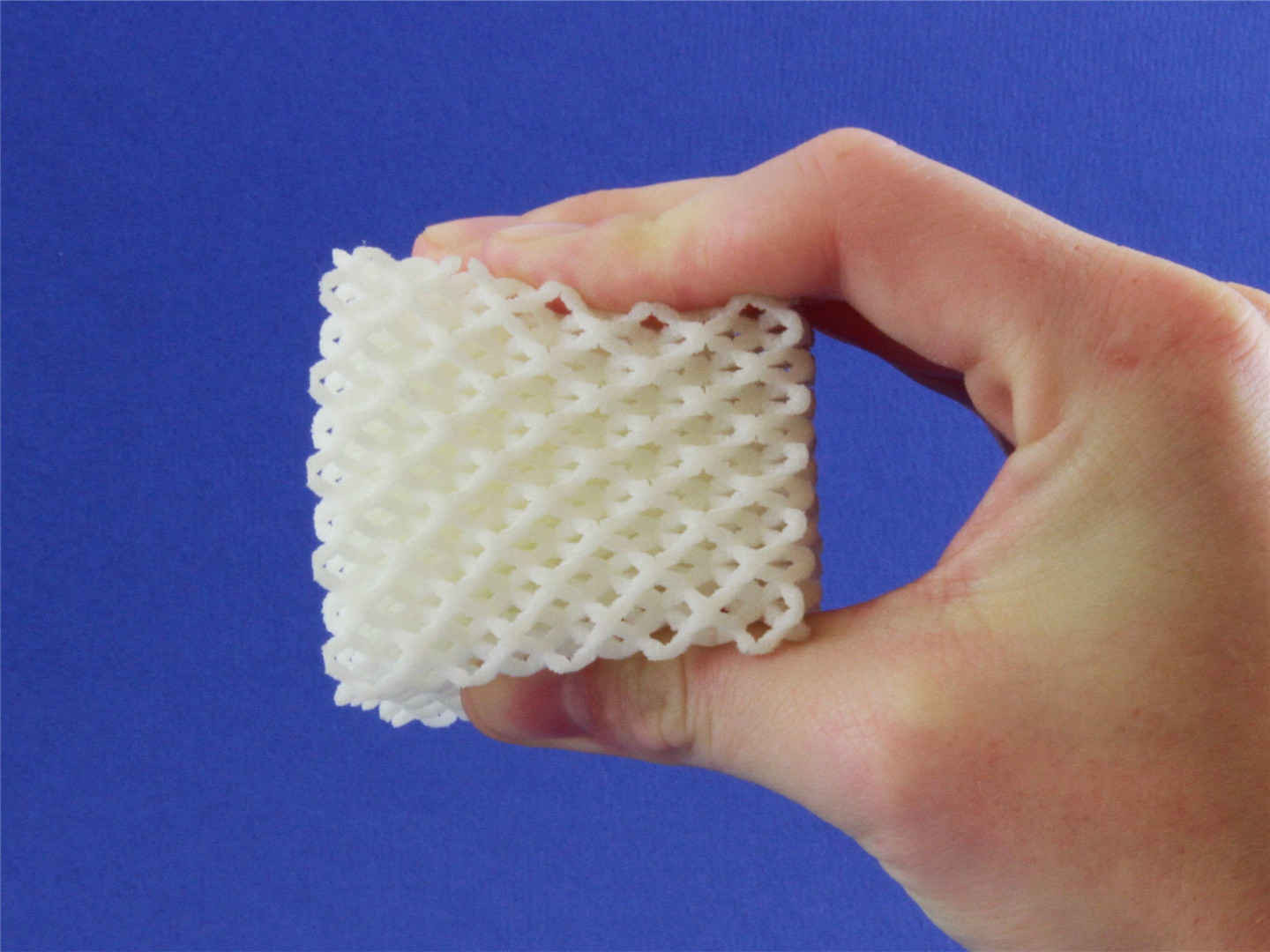

SLS process is highly beneficial for those who need to produce their plastic parts for prototyping and simulation, or for low-volume production by eliminating time-consuming tooling. With Selective Laser Sintering (SLS), it’s also possible to get thin-walled objects and intricate geometries.

Selective Laser Sintering can be used to make parts using a variety of materials, including plastic, metal, ceramic, or glass powder, making it a popular machining process.

Selective Laser Sintering (SLS) as other metal 3D printing technologies is appropriate for manufacturing small batches at a reasonable unit costs and a high degree of product customization even in serial production. We have a strong expertise in the production of series with SLS technology.

Unlike stereolithography(SLA) and fused deposition modeling (FDM), Selective Laser Sintering (SLS) does not need a separate feeder for support material because the part being constructed is surrounded by unsintered powder at all times, this allows for the construction of previously impossible geometries.

Benefits Of SLS Rapid Prototyping Services With FacFox

Thanks to our online SLS service, you can have access to professional 3D printers for prototyping and production distantly, and without needing to worry about operating the machines yourself. You’ll get your 3D printed plastic parts, fully functional and ready to be used or integrated into a larger object, within a few days.

MJF vs SLS

Features of SLS 3D Printing

Advantages

Drawbacks

SLS Processes

Printers & Parameters – Printers: EOS P760/P396, Farsoon FS403P – Maximal build volume: 700 x 380 x 580 mm – Minimum feature size: 0.15 mm Restrictions – Minimum layer thickness: 0.1 mm – Typical surface finish: 5 ŌĆō 10 microns RA – Accuracy: (+/- 0.1-0.2%) Pre-build planning Important decision on design is the orientation and support structures. This depends on: – Geometry, mainly inclination to reduce layer lines. – Areas that need great smoothness or post-processing

Available Materials

Available Finishes

The finish option with the quickest turnaround. Which normally includes:

- Removal of build envelope: The build envelope is removed from the machine

- Remove powder: Parts are broken out of the powder cake. Afterwards excess powder is removed from the parts by sand blasting. This is usually straight forward, however might require some extra effort for parts with complex geometric features (e.g. trapped powder)

In addition to the removal of remaining powder, the part surface is media blasted to provide a uniform finish.

- Media Polishing

- Painting

- Dyeing(Only black available for now)

- UV Coating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

SLS Applications

Prototypes With SLS, the prototype can be made using nylon material with great functionality. Fast turnaround makes it a good choice for functional prototyping.

Customized Productscts The speed and versatility of SLS let variable production of customized gifts/samples for different users become possible.

Batched Products SLS can be applied to make high-quality small batched products from 1-10,000 units, ideal for small businesses that wishes to test the market’s reaction to thier newly developed products.

Industries with SLS

Resources for SLS