- SLA 3D Printed Scaled-Down Tactical Truck Resin Model

- High-Resolution SLA 3D Printing for Urban Design

Material Resin

Quantity 3 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

Say hello to the future of desktop robotics! This custom-built 6-DOF torso is a masterclass in how 3D printing is bridging the gap between hobbyist prototypes and production-ready hardware.

Despite its compact scale, this robot is designed for high-dexterity movement. With multiple servos tucked into each arm, it’s the perfect platform for testing inverse kinematics, computer vision, or even small-scale lab automation. What really sets this build apart, though, is the surface finish. By using industrial-grade post-processing and a multi-stage metallic paint job, we’ve transformed raw 3D printed shells into a sleek, “die-cast” aesthetic that looks like it walked straight out of a high-tech R&D lab.

Whether it’s mounted on a stationary lab stand or a mobile base, this little powerhouse proves that “small” doesn’t mean “simple.” It’s a functional piece of tech that looks as good as it moves!

Ready to bring your own robot to life?

If you’re looking to achieve this level of professional finish for your next project, look no further than FacFox. As a leading one-stop shop for digital manufacturing, FacFox’s 3D printing service offers everything from high-resolution SLA resin printing (ideal for those smooth, aerodynamic curves) to industrial SLS nylon for functional, high-stress joints. Beyond just printing, their expert team provides professional post-processing and custom painting, ensuring your prototype doesn’t just work-it looks like a finished product. Visit FacFox.com to get an instant quote and turn your digital designs into physical reality today!

Solution

- Step 1: The structural components and aesthetic outer shells were designed using CAD software to ensure precise tolerances for the internal servos.

- Step 2: All parts were 3D printed using high-resolution technology to capture the intricate details of the torso and limbs.

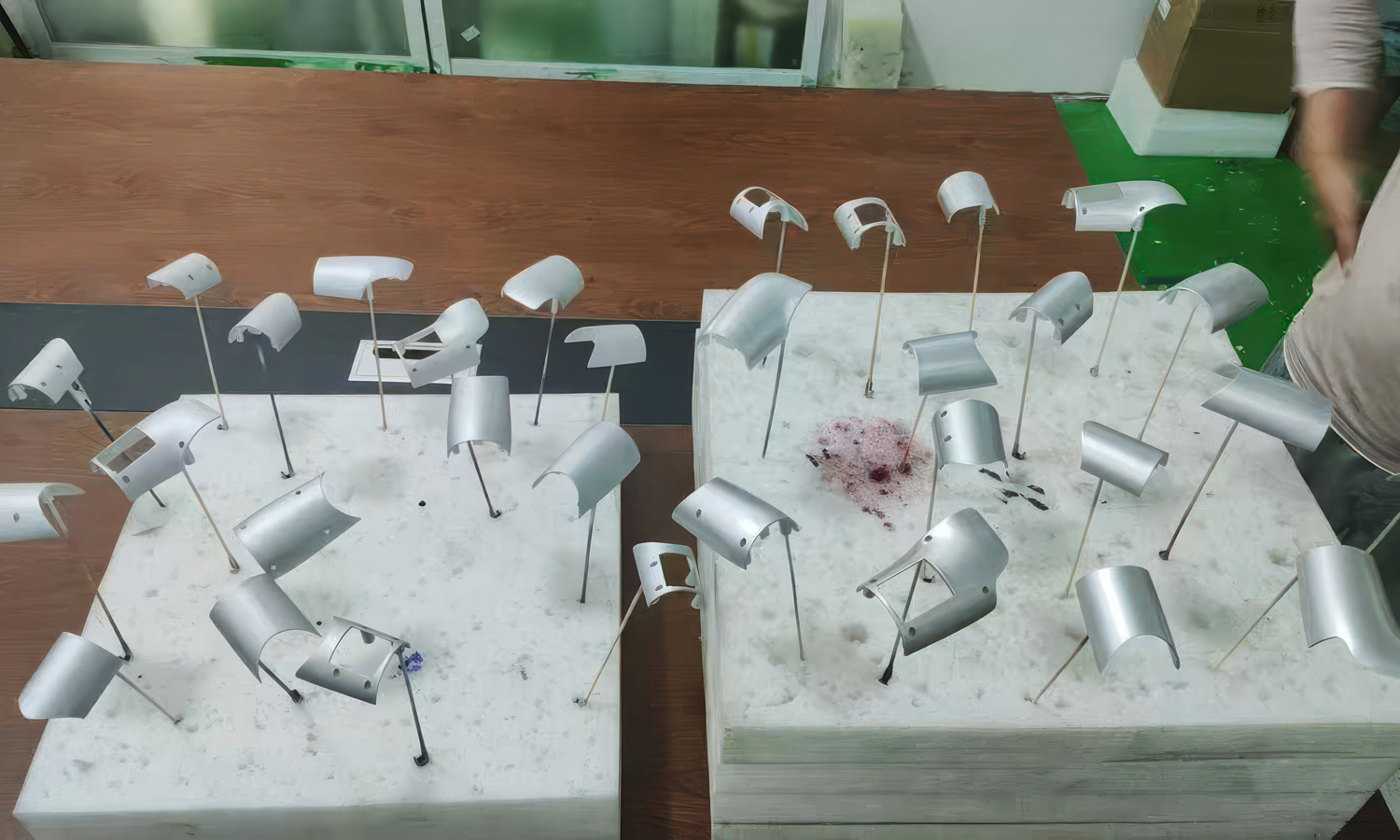

- Step 3: The raw printed surfaces were meticulously sanded and treated with high-build primer to eliminate all visible layer lines.

- Step 4: A premium metallic silver coating was applied in a controlled environment and finished with a protective clear coat for a production-grade look.

- Step 5: The high-torque servo motors and complex wiring harnesses were integrated into the arm joints and chest cavity.

- Step 6: The completed upper body was mounted onto a reinforced aluminum extrusion stand for final testing and calibration.