- FDM 3D Printed Large White ABS Pipe Fitting Plug

- PolyJet 3D Printed Full-color Resin White Power Ranger Miniature with Saba Sword

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

If you are looking for a way to store and protect your batteries, you might be interested in this LCD 3D printed detailed tough resin battery holder prototype. This is a custom design that was created using LCD 3D printing technology, which offers high resolution, accuracy, and durability.

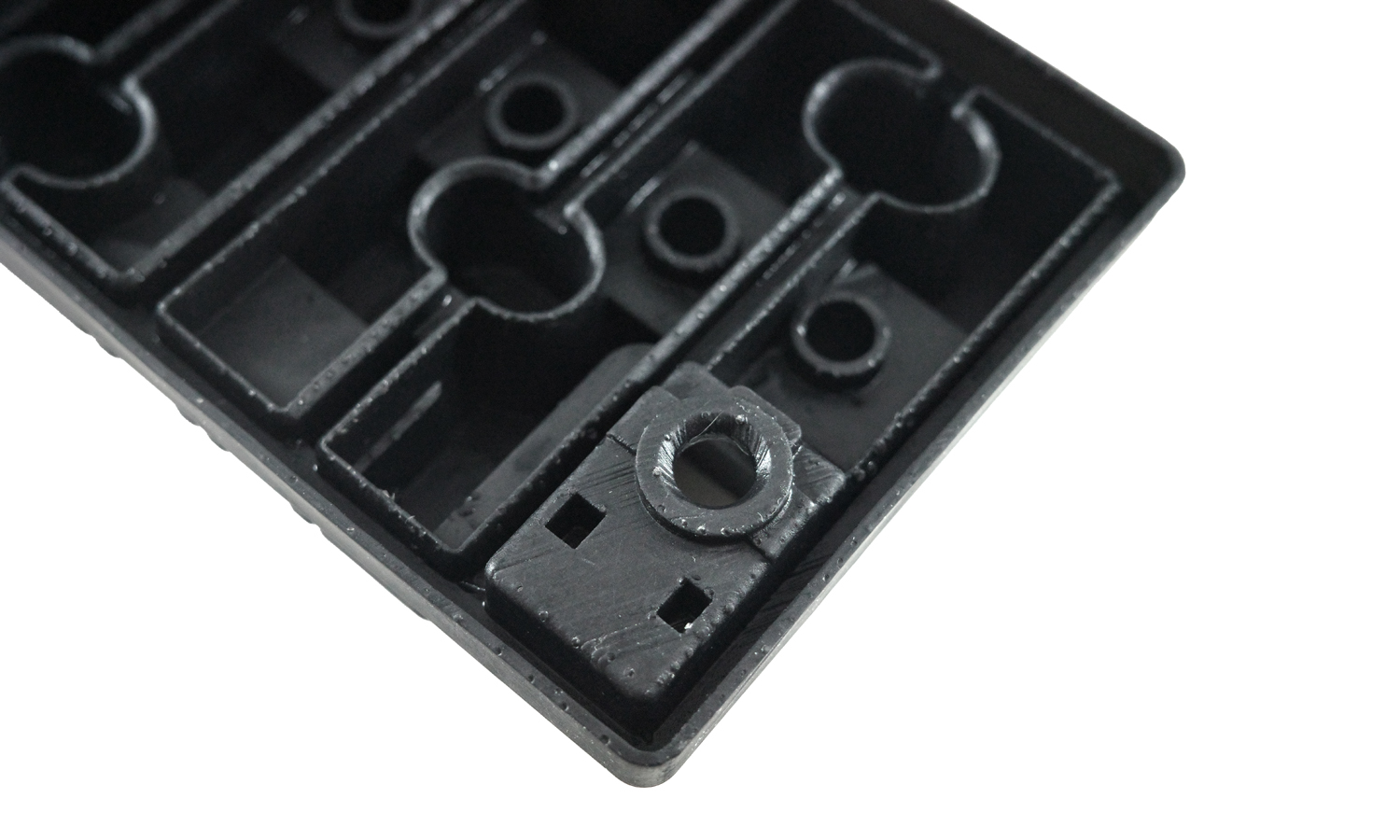

The battery holder prototype has a rectangular shape with rounded edges, and it is all black. It has an array of six small holes in the middle. On the front half, there are two slots in the middle, and two grooves on the corner to load batteries. There are cathode and anode icons located between them to indicate the correct polarity. The battery holder has a snug fit structure to prevent the batteries from falling out.

The battery holder prototype was printed using LCD Detailed Tough Resin, which is a material that combines high strength, hardness, and impact resistance. This material is ideal for functional prototypes and mechanical parts that require high precision and durability. The LCD Detailed Tough Resin also has a matte black color, which gives the battery holder prototype a professional look.

The battery holder prototype was printed by FacFox, a leading online platform for LCD 3D printing services. FacFox offers fast, reliable, and affordable LCD 3D printing solutions for various applications and industries. Whether you need a single prototype or a large batch of parts, FacFox can handle your LCD 3D printing needs with ease. You can upload your 3D model, choose your material and color, and get an instant quote and delivery time. FacFox also provides quality assurance and customer support to ensure your satisfaction.

If you want to learn more about LCD 3D printing or order your own battery holder prototype, visit FacFoxŌĆÖs website facfox.com today. You will be amazed by the possibilities and benefits of LCD 3D printing. FacFox is your trusted partner for LCD 3D printing services.

Solution

- Step 1: The 3D model of the battery holder prototype was programmed on a computer and uploaded to the LCD 3D printer.

- Step 2: The printer generated an image of the model layer as masks on the LCD matrix, which emitted UV light.

- Step 3: The light cured the LCD Detailed Tough Resin in the areas where the matrix had transmitted UV rays, creating a three-dimensional model.

- Step 4: The build platform was lifted up by one layer, and the process was repeated until the entire model was completed.

- Step 5: The model was removed from the resin tank and washed with isopropyl alcohol to remove any excess resin.

- Step 6: The model was cured under UV light for a few minutes to enhance its strength and durability.

- Step 7: The model was inspected for any defects or errors and polished if needed.