Gallery

About Project

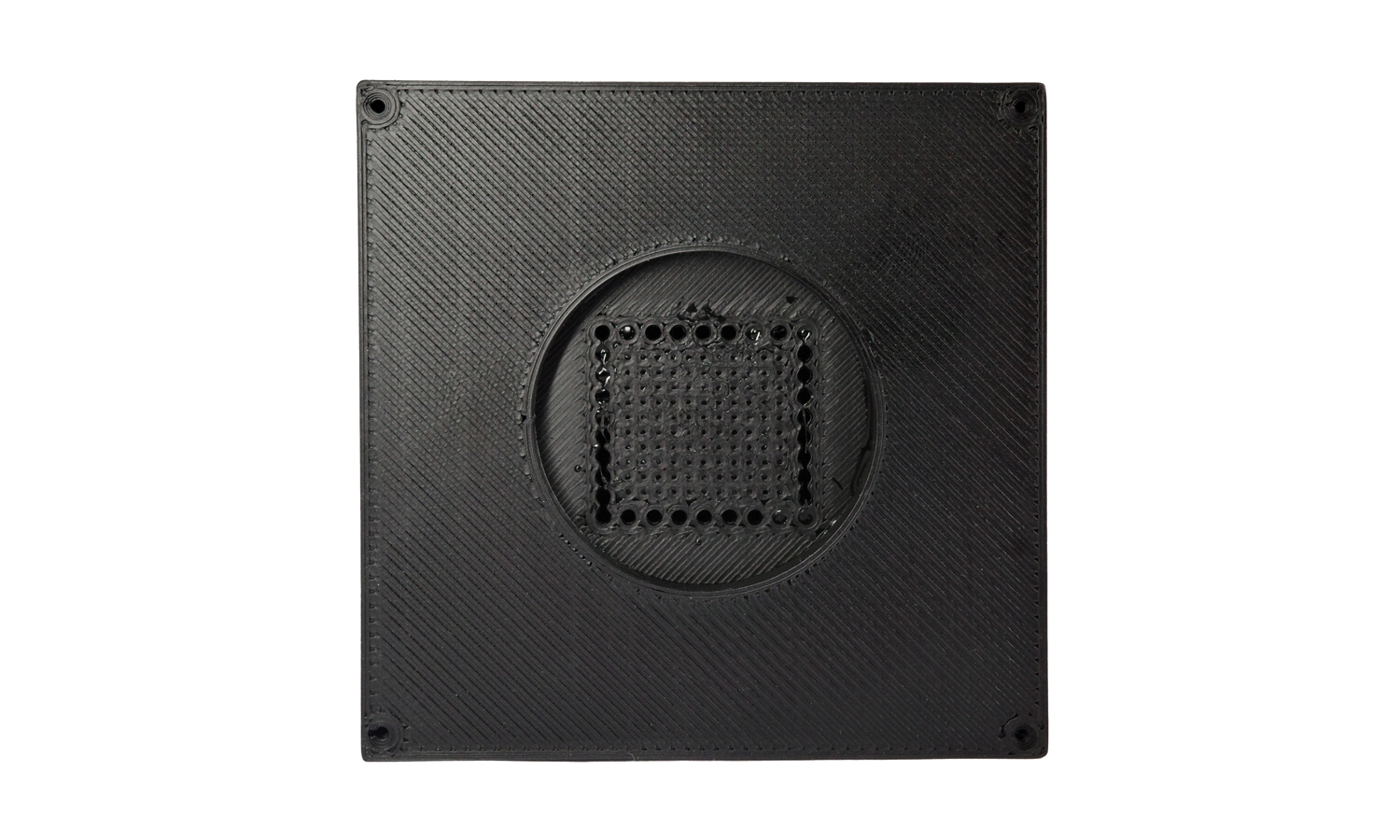

Are you looking for a unique and functional 3D-printed box that can store your electronic gadgets or accessories? If so, you might want to check out this FDM 3D Print Electric PLA Box with Extruding Cylinders. This box is printed with Electric Black PLA filament, which gives it a┬Āglossy surface┬Āand a┬Āmetallic sheen. The box has┬Āfour extruding thin cylinders┬Āon one of its faces, which can be used as the┬Āhousing for sensors, batteries, or other components. The box has┬Āuniform layer lines┬Āand a┬Āsmooth finish, thanks to the high-quality FDM 3D printing process.

This box is made by FacFox, a leading online platform for custom 3D printing and manufacturing services. FacFox offers a wide range of materials, technologies, and post-processing options for your 3D printing needs. You can upload your own design or choose from their library of ready-to-print models. FacFox also provides professional design assistance, quality control, and fast delivery. Whether you need a single prototype or a large-scale production, FacFox can help you turn your ideas into reality.

If you are interested in this FDM 3D Print Electric PLA Box with Extruding Cylinders, you can order it from FacFoxŌĆÖs website. You can also browse their other products and services, such as CNC machining, injection molding, sheet metal fabrication, and more. FacFox is your one-stop shop for all your 3D printing and manufacturing needs. Order today and get your products delivered to your doorstep in no time!

Solution

- Step 1: The design of the box was created in 3D modeling software, such as Fusion 360, SketchUp, or Blender. The design was saved as an STL file, which is a standard format for 3D printing.

- Step 2: The STL file was uploaded to FacFoxŌĆÖs website, where the user selected the material, color, and print settings for the box. The user chose Electric Black PLA filament, which is a thermoplastic polymer that can be melted and extruded by a heated nozzle.

- Step 3: The STL file was sliced by FacFoxŌĆÖs software, which converted the 3D model into a series of thin layers and generated the instructions for the FDM 3D printer. The slicing software also added support structures to the model, which are needed to prevent sagging or collapsing of overhanging parts.

- Step 4: The FDM 3D printer was loaded with Electric Black PLA filament and heated up to the optimal temperature. The printer started to print the box layer by layer, following the instructions from the slicing software. The printer extruded the filament through a nozzle and deposited it on a heated build plate, where it solidified and bonded with the previous layer. The printer repeated this process until the box was completed.

- Step 5: The printed box was removed from the build plate and cooled down. The support structures were carefully removed from the box using pliers or a knife. The box was inspected for any defects or errors and cleaned with a soft cloth or a brush.