- MJF 3D Print PP Engineering Structural Component Dyed Black

- FDM 3D Print Electric PLA Box with Extruding Cylinders

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

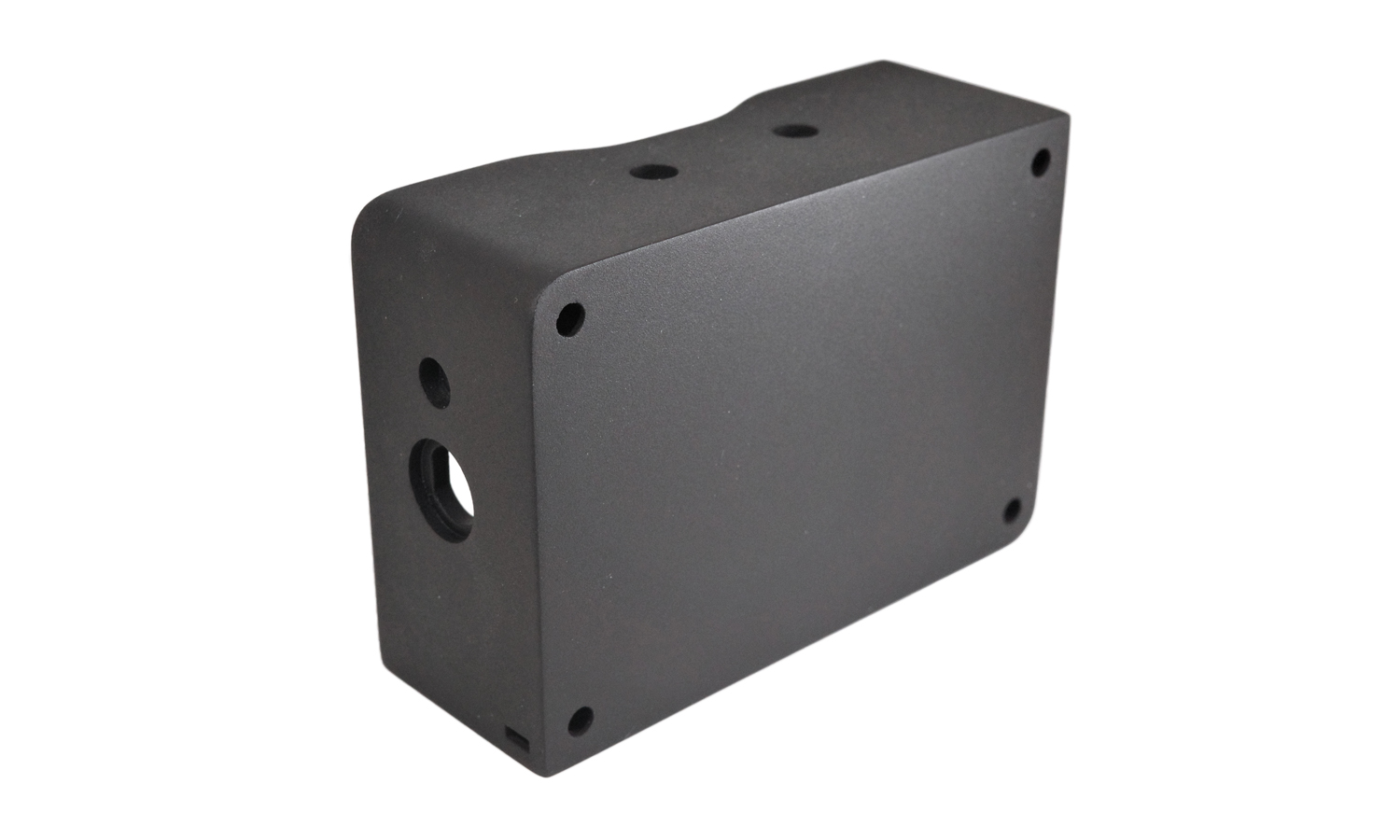

If you are looking for a sleek and elegant box to store your precious items, you might want to check out the SLA 3D Printed PWR Dark Black Resin Box. This box is made from a new material called SLA PWR Dark Black Resin, which is a high-performance resin that offers excellent mechanical properties and a smooth and jet-black surface.

The SLA PWR Dark Black Resin Box is created using a 3D printing technique called stereolithography (SLA), which uses a laser to cure liquid resin into solid layers. The result is a box that has a high level of detail and accuracy, as well as a smooth and glossy finish.

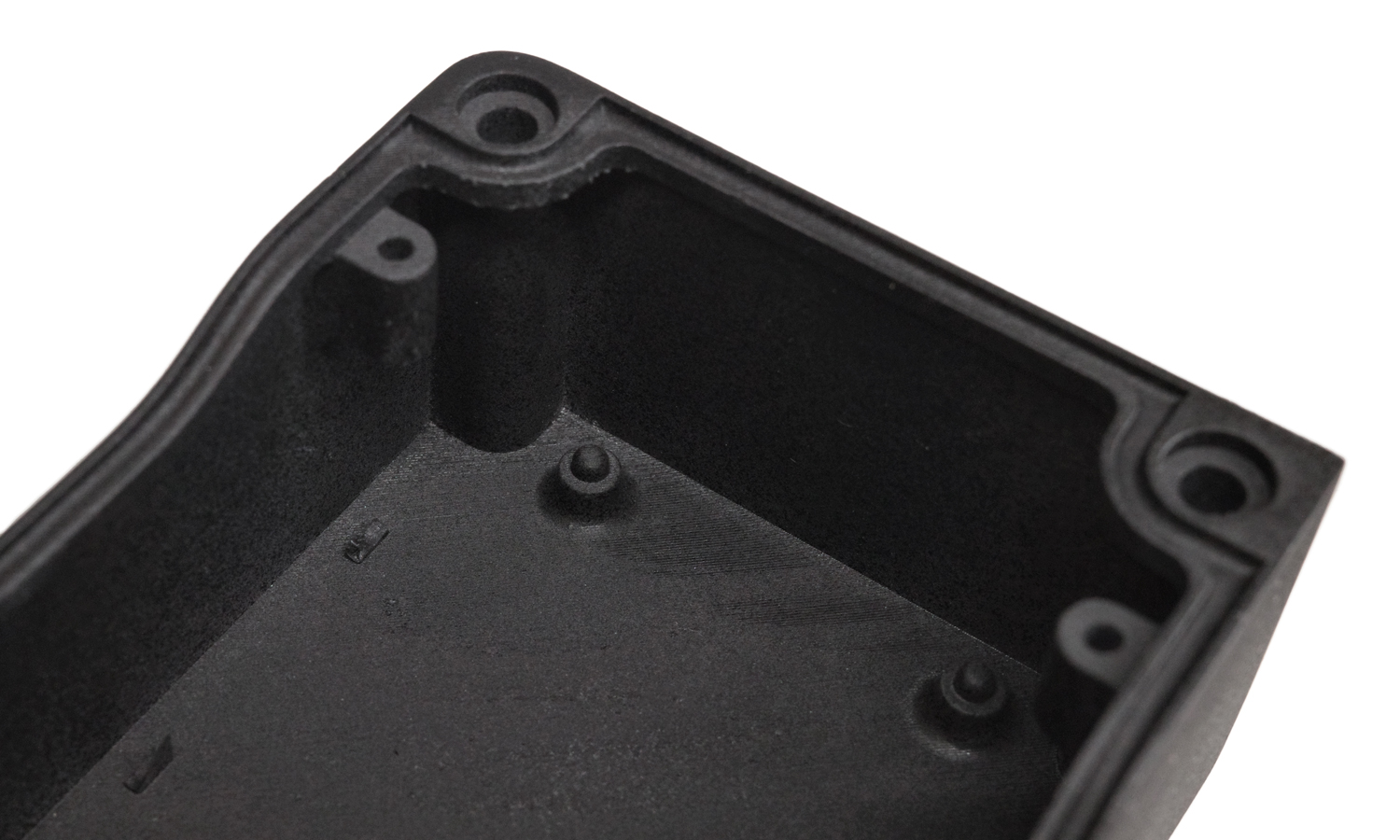

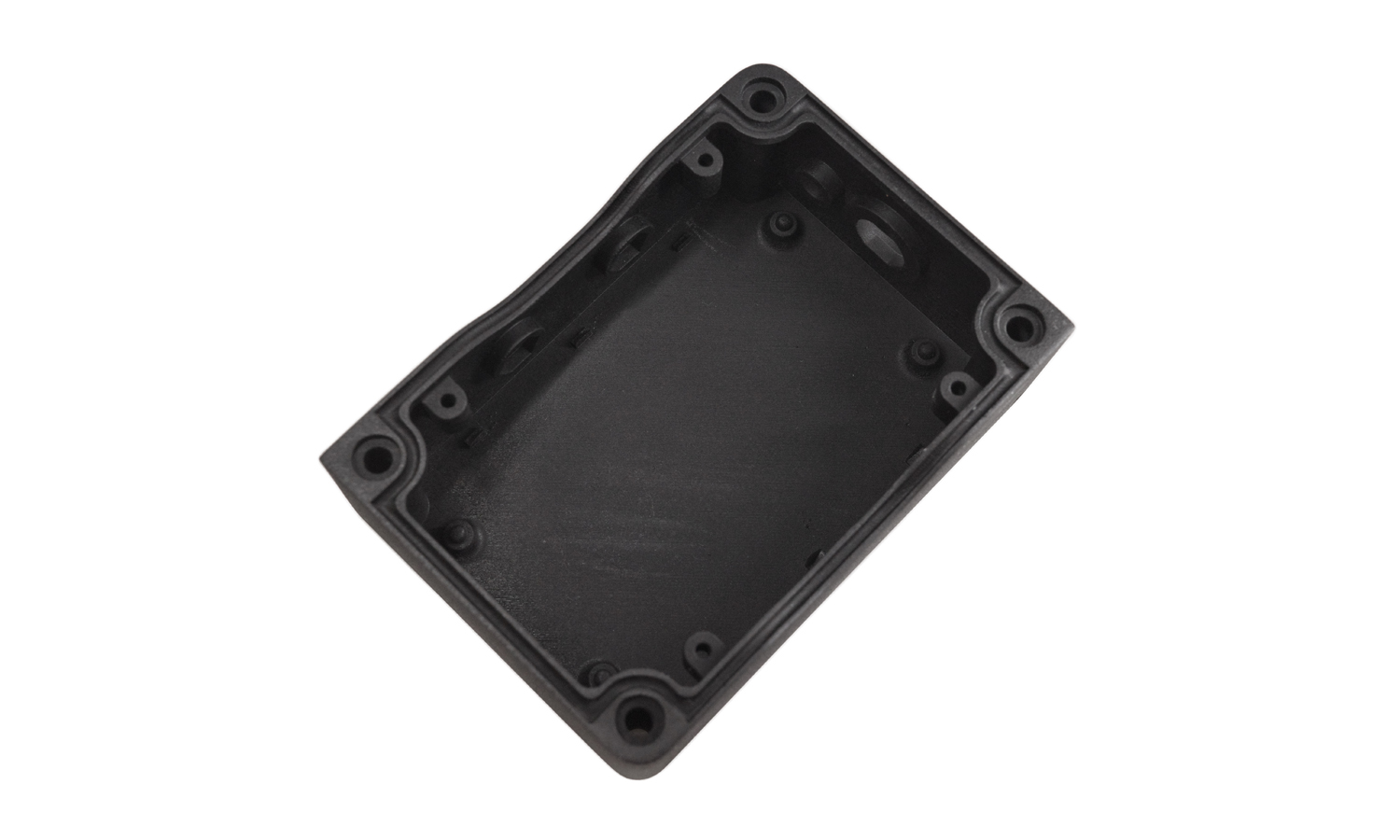

The outside of the box has been fine polished and sprayed with wax pigment, giving it a luxurious and sophisticated look. The inner bottom of the box also has a wax cover, but without polishing or sanding, so it has a textured surface with visible layer lines.ô

If you are interested in getting your own SLA PWR Dark Black Resin Box, you can order it from FacFox, a leading online platform for custom 3D printing services. FacFox offers a wide range of materials, colors, and finishes for your 3D printing needs, as well as fast turnaround times and competitive prices. You can upload your own design or choose from thousands of ready-made models on their website. FacFox will print your order with high quality and deliver it to your doorstep in no time.

FacFox is your one-stop shop for all your 3D printing projects. Whether you need a prototype, a product, or a gift, FacFox can help you turn your ideas into reality. Visit their website today and start creating your own SLA PWR Dark Black Resin Box!

Solution

- Step 1: A 3D model of the box was uploaded to FacFoxãs website and the SLA PWR Dark Black Resin material was selected.

- Step 2: The 3D model was sliced into thin layers by a software program and sent to an SLA 3D printer.

- Step 3: The SLA 3D printer used a laser to cure liquid resin into solid layers, building the box from bottom to top on a platform that moved up and down.

- Step 4: The box was removed from the platform and washed with alcohol to remove any excess resin.

- Step 5: The box was placed in a UV oven to cure and harden the resin completely.

- Step 6: The box was sanded and polished by hand to smooth out any rough edges or bumps.

- Step 7: The box was sprayed with wax pigment to give it a glossy and jet-black finish.

- Step 8: The box was inspected for quality and packaged for delivery.