- CNC Milled and Polished Mercedes-Benz Hood Ornament Customization

- Service alert: Moving our office on June.5-6!

Gallery

About Project

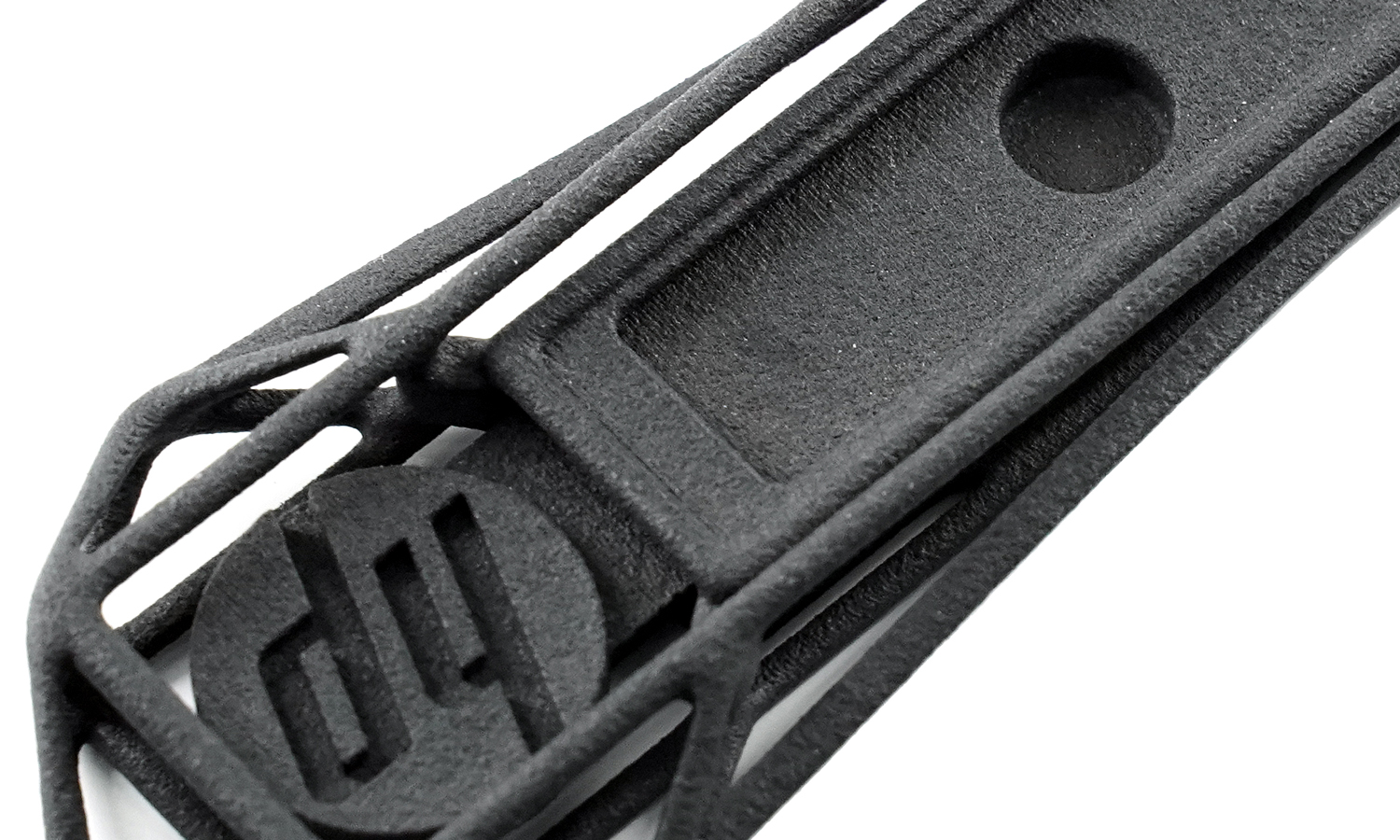

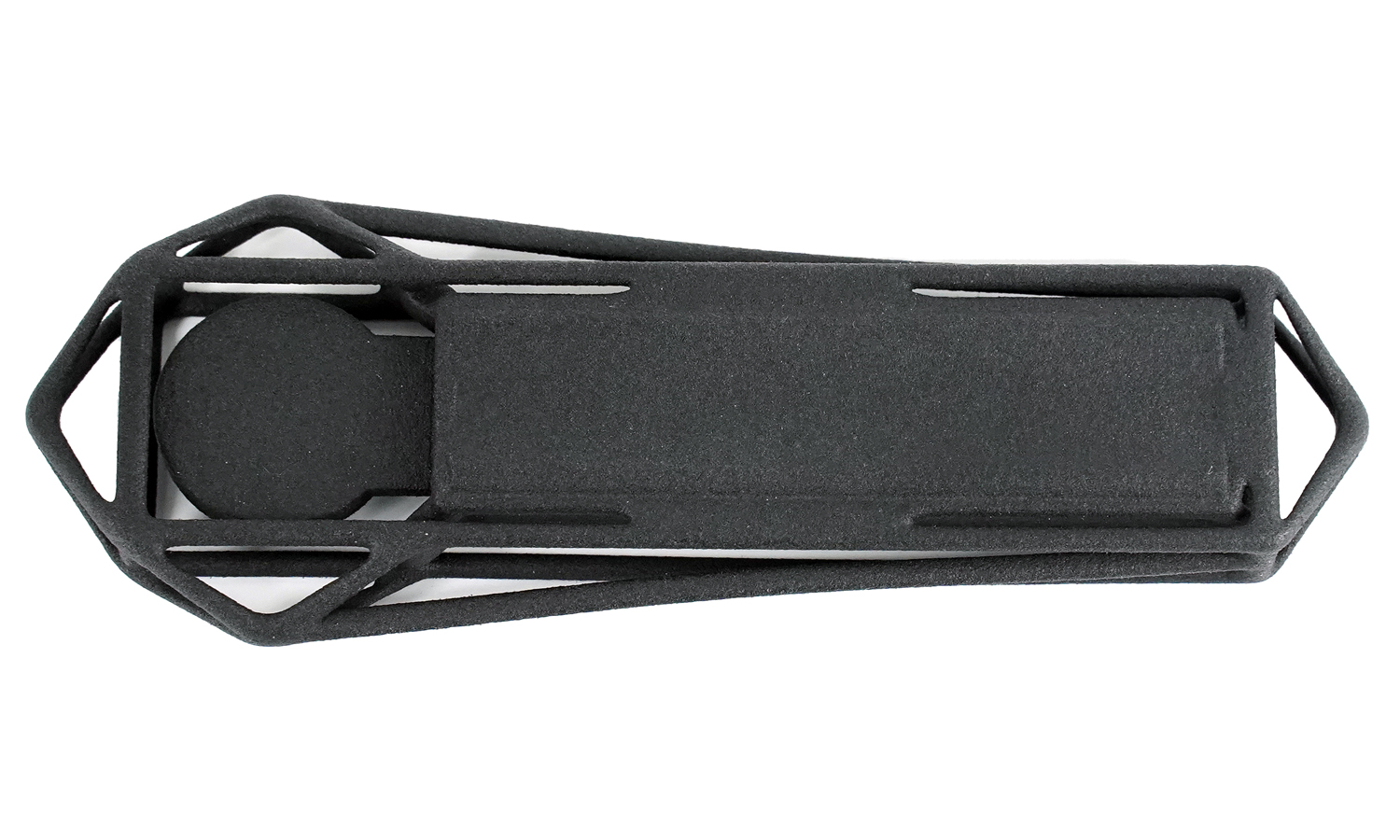

Have you ever wondered what a MJF 3D printed nylon PA 12 part looks like? Check out this sample part with raw finishing that showcases the excellent mechanical properties and dimensional accuracy of this material.

Nylon PA 12 is a versatile thermoplastic that can be used for various applications such as functional prototypes, end-use parts, gears, hinges, brackets, and more. It has high strength, stiffness, impact resistance, and durability. It also has good resistance to chemicals, moisture, and UV light.

If you are interested in 3D printing with nylon PA 12, you should try FacFoxвҖҷs MJF 3D printing service. FacFox is a leading online 3D printing platform that offers high-quality and affordable MJF 3D printing solutions. You can upload your 3D model, choose your material and finishing options, and get an instant quote. FacFox will print your part with their advanced MJF machines and ship it to you in no time. Whether you need a single part or a large batch, FacFox can handle it with ease.

DonвҖҷt miss this opportunity to get your own MJF 3D printed nylon PA 12 sample part with raw finishing. Visit FacFoxвҖҷs website today and order yours now! You will be amazed by the results.

Solution

- Step 1: First, the 3D model will be broken down into layers of 0.1 mm on the computer and sent to the 3D printer.

- Step 2: Before printing, we need to fill the tank with MJF Nylon PA12 powders. On a bed pressure, a 0.1 mm thick layer over the whole width is applied.

- Step 3: The material recoater carriage moves across the build area, depositing a thin layer of the powder material. The printing and fusing carriage moves across the build area, preheating the powder to a specific temperature to provide material consistency.

- Step 4: An array of inkjet nozzles fuses agents onto the powder bed in areas that correspond to the partвҖҷs geometry and properties. After each layer is finished, the build unit retracts to create space for the next layer of material to be deposited.

- Step 5: This process repeats until the build is completed. When the printing process ends, remove the excess powders which also serve as supports.