Multi Jet Fusion (MJF) 3D Printing Service

Industrial 3D printing process that produces functional nylon prototypes and end-use production parts in as fast as 1 day.

Make nylon parts starting at only $25!

Overview: How MJF 3D printing works?

The Basics Of MJF 3D Printing Service

Multi Jet Fusion is an additive manufacturing method invented and developed by the company Hewlett-Packard (HP). It creates parts additively thanks to a multi-agent printing process.

Final parts exhibit quality surface finishes, fine feature resolution, and ã˜more consistent mechanical properties when compared to processes like selective laser sintering.

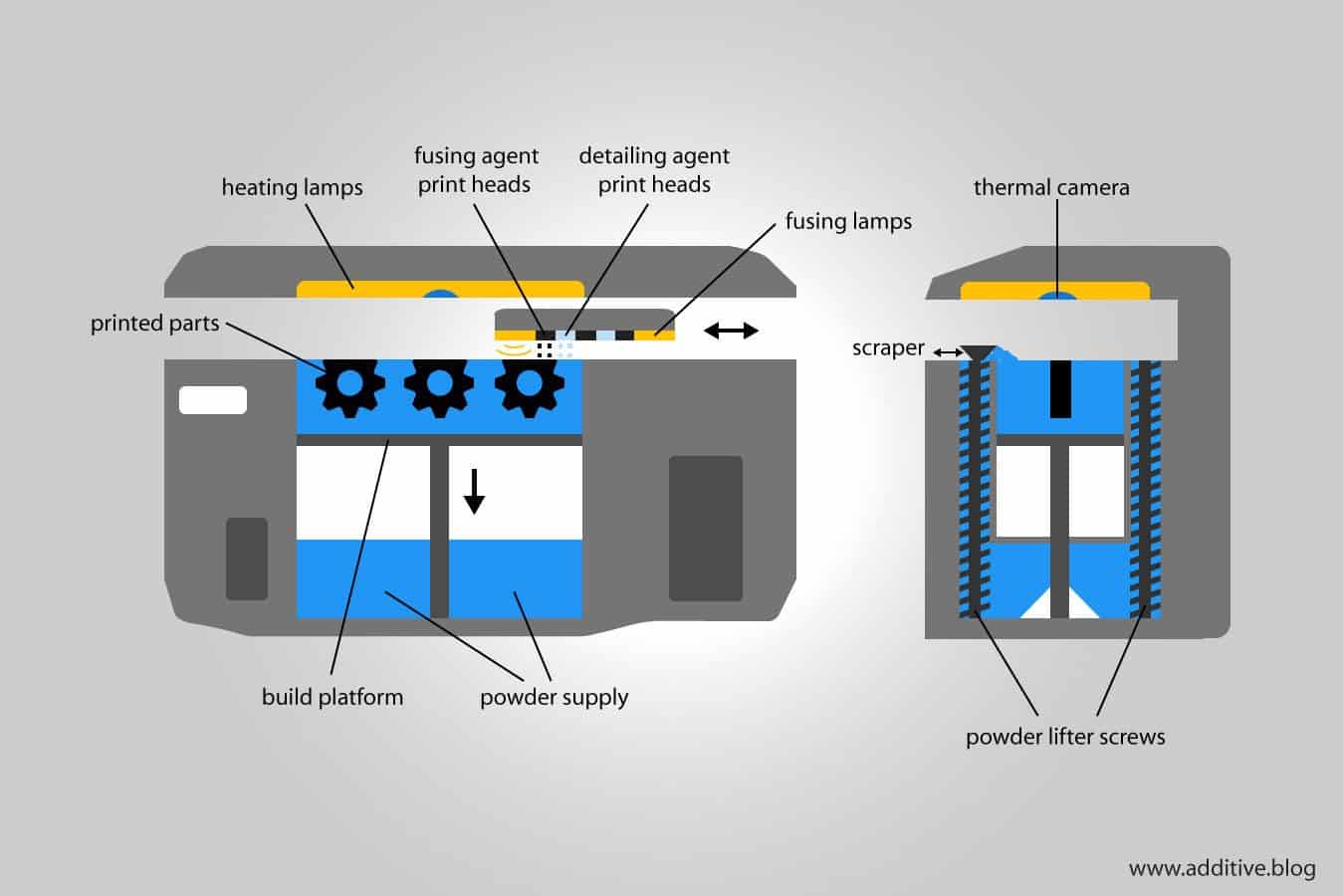

Multi Jet Fusion uses an inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which are then fused by heating elements into a solid layer. After each layer, powder is distributed on top of the bed and the process repeats until the part is complete.

When the printing process is complete, the build box is removed from the printer. A n operator carefully extracts the parts from the build box and removes the remaining powder thanks to brushes and air blowers.

Benefits Of MJF 3D Printing Service

The Multi Jet Fusion process is one of the fastest plastic 3D printing technology. In comparison to FDM or SLS technologies, HP Multi Jet Fusion can 3D print up to 10x faster theoretically. Thanks to this speed you can receive your parts quickly. It’s the perfect choice for prototyping or manufacturing.

Multi Jet Fusion can create complicated and highly detailed design in a very short amount of time. Jet Fusion plastic is great for both beginning designers and experienced professionals because of its high precision and low cost. It’s also much more durable and flexible than SLA printed resin parts, and detailed than FDM printed plastic parts.

The main benefits of the Multi Jet Fusion technology is the high customization possibilities and the fast production time. Also, another benefit is the fact that our non-dyed MultiJet material, is a low-priced material and a great economical choice. This material is ideal for prototyping and mechanical tests, even for some end products.

Benefits Of Multi Jet Fusion (MJF) 3D Printing Service With FacFox

Thanks to our online Multi Jet Fusion service, you can have access to professionnal Multi Jet Fusion 3D printers to produce your part, distantly, and without needing to worry about operating the machines. You’ll get your 3D printed Multijet Fusion PA12 parts, fully functional and ready to be used or integrated into a larger object, within a few days.

MJF vs SLS

Features of MJF 3D Printing Service

Advantages

Drawbacks

MJF Processes

Printers & Parameters – Printers: HP MJF 4200/3200/580 Color – Maximal build volume: 380 x 284 x 380 mm – Minimum feature size: 0.1-0.2 mm Restrictions – Minimum layer thickness: 0.08 mm – Typical surface finish: 2 ã 10 microns RA – Accuracy: (+/- 0.1-0.2%) Pre-build planning Important decision on design is the orientation and support structures. This depends on: – Geometry, mainly inclination to reduce layer lines. – Areas that need great smoothness or post-processing, color texture of the 3D model

Available Materials

Available Finishes

The finish option with the quickest turnaround.

In addition to the removal of remaining powder, the part surface is media blasted to provide a uniform finish.

- Painting

- UV Coating

- Donãt see the finish you need? Submit an RFQ with ‘Suggest’ option, weãll look into a finishing process for you.

MJF Applications

Prototypes With MJF, the prototype can be made using nylon material with great functionality. Fast turnaround makes it a good choice for functional prototyping.

Customized Products The speed and versatility of MJF let variable production of customized gifts/samples for different users become possible.

Batched Products MJF can be applied to make high-quality small batched products from 1-10,000 units, ideal for small businesses that wishes to test the market’s reaction to thier newly developed products.

Industries with MJF

Resources for MJF