- CNC Milled SS304L Four-leaf Clover Mold with Brushed Surface

- CNC Milled Die Steel Table Saw Zero Clearance Insert

Gallery

About Project

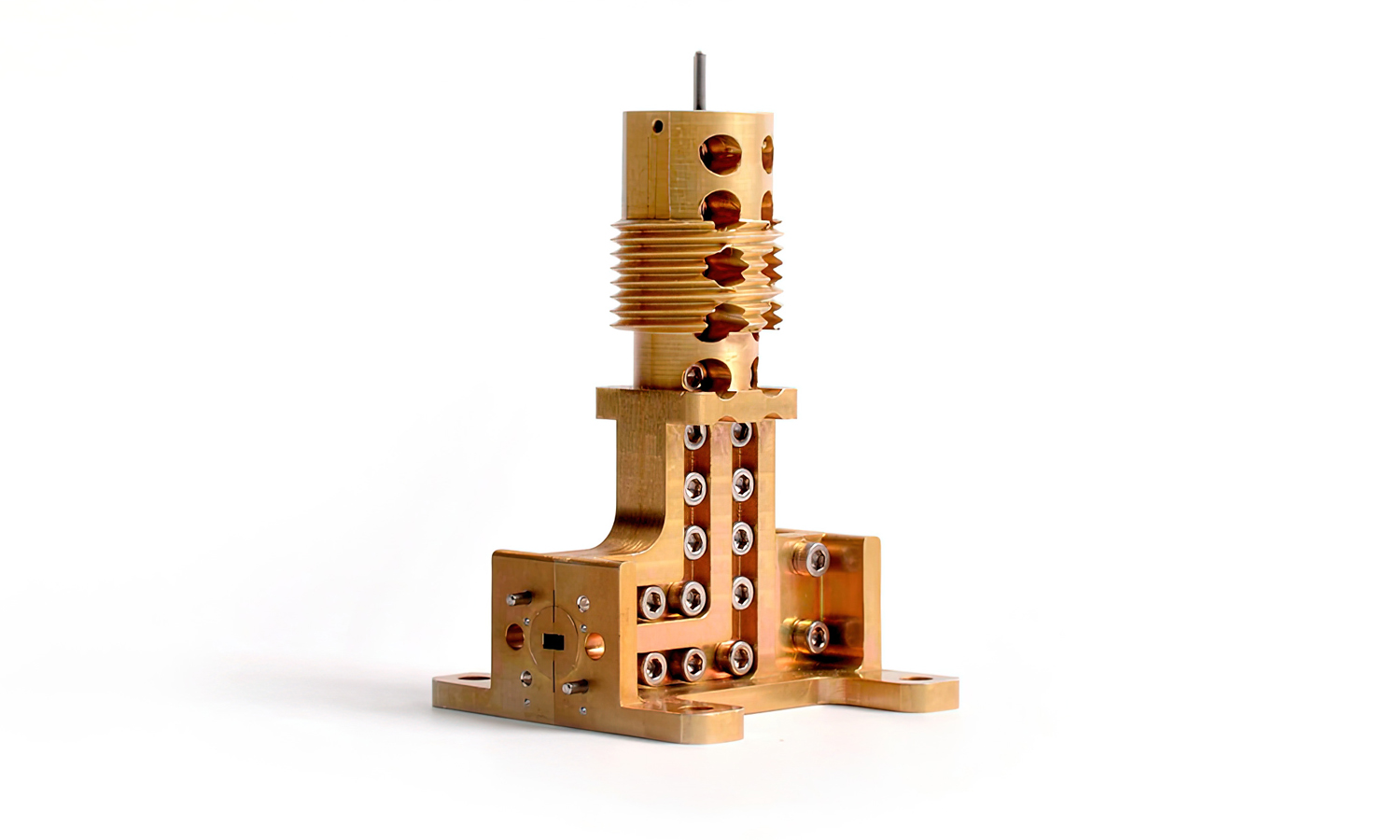

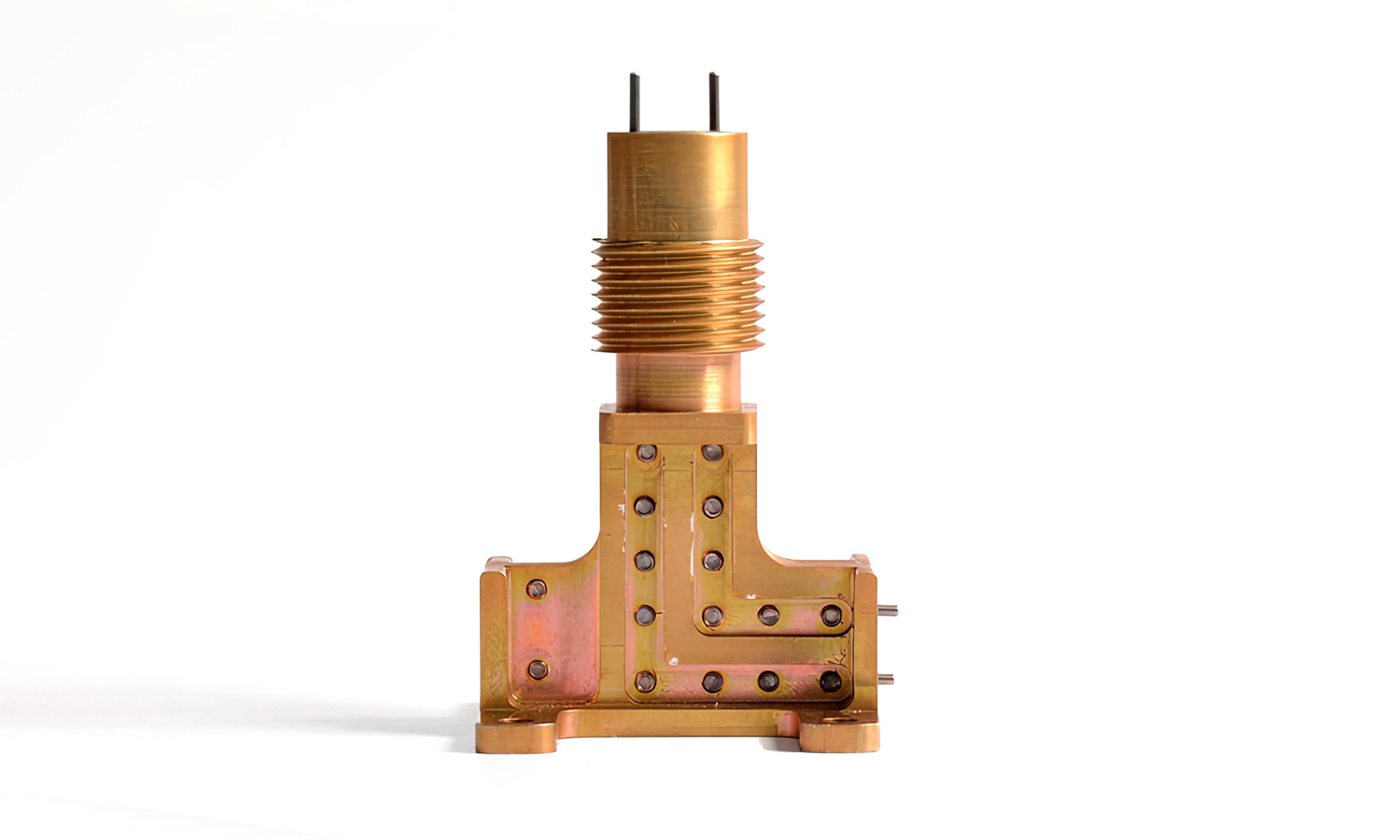

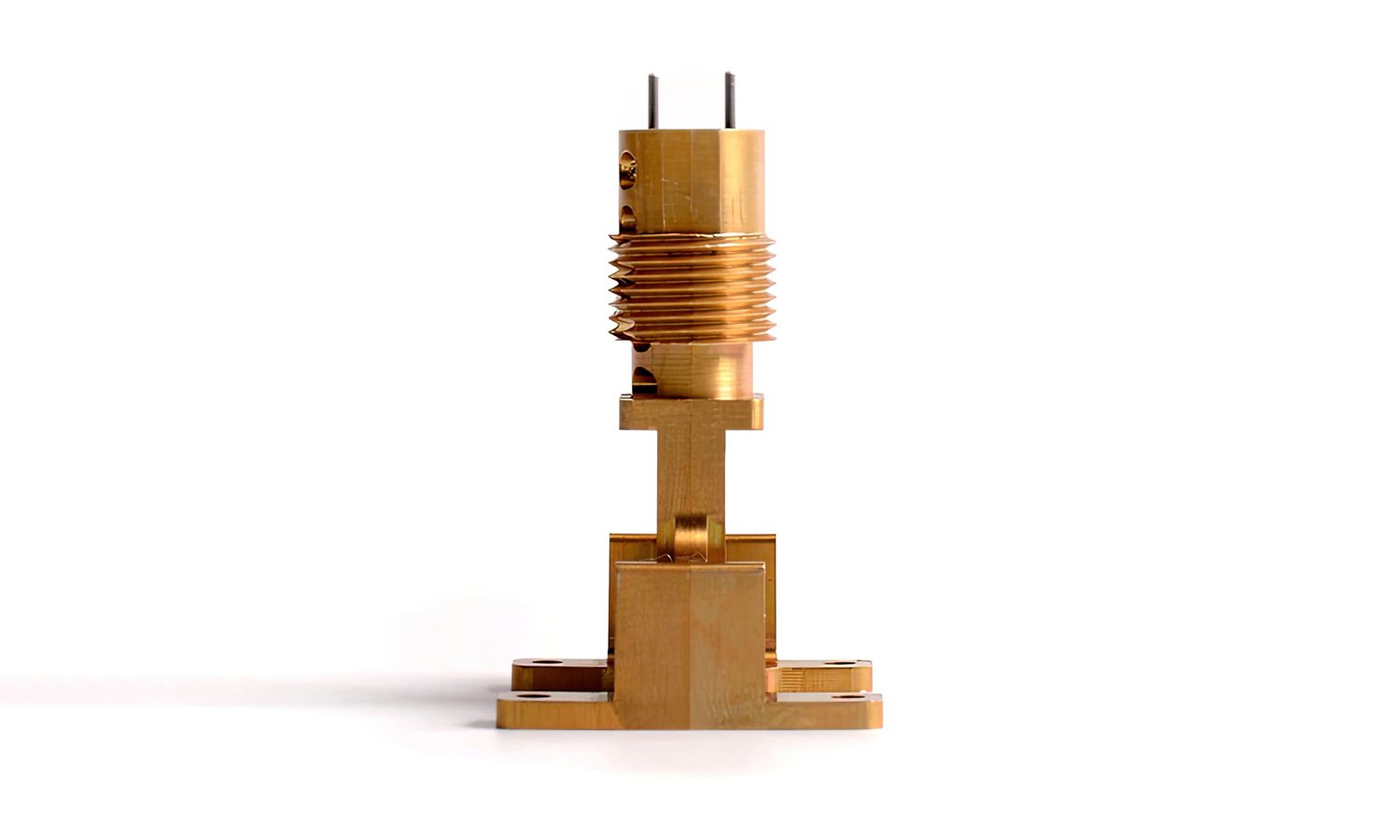

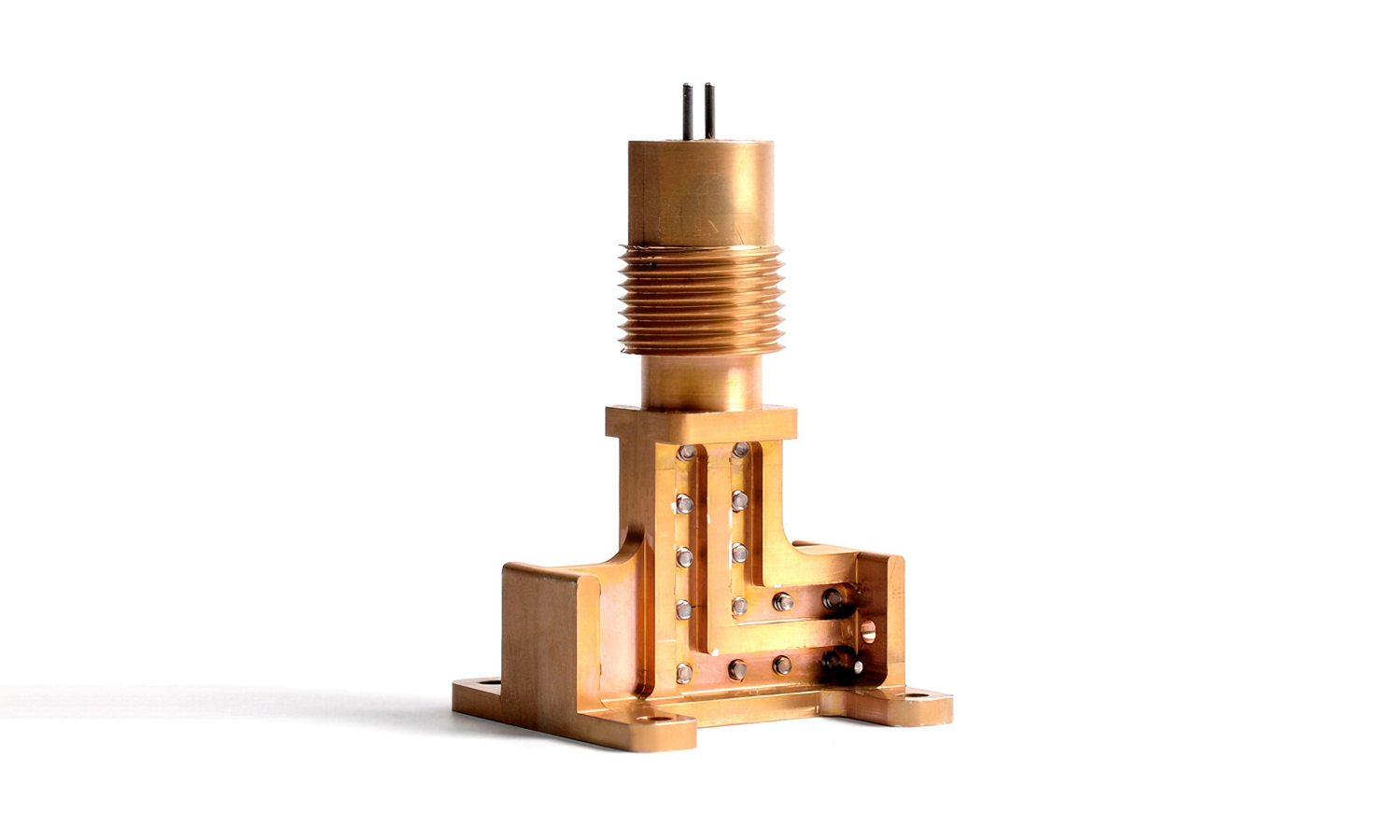

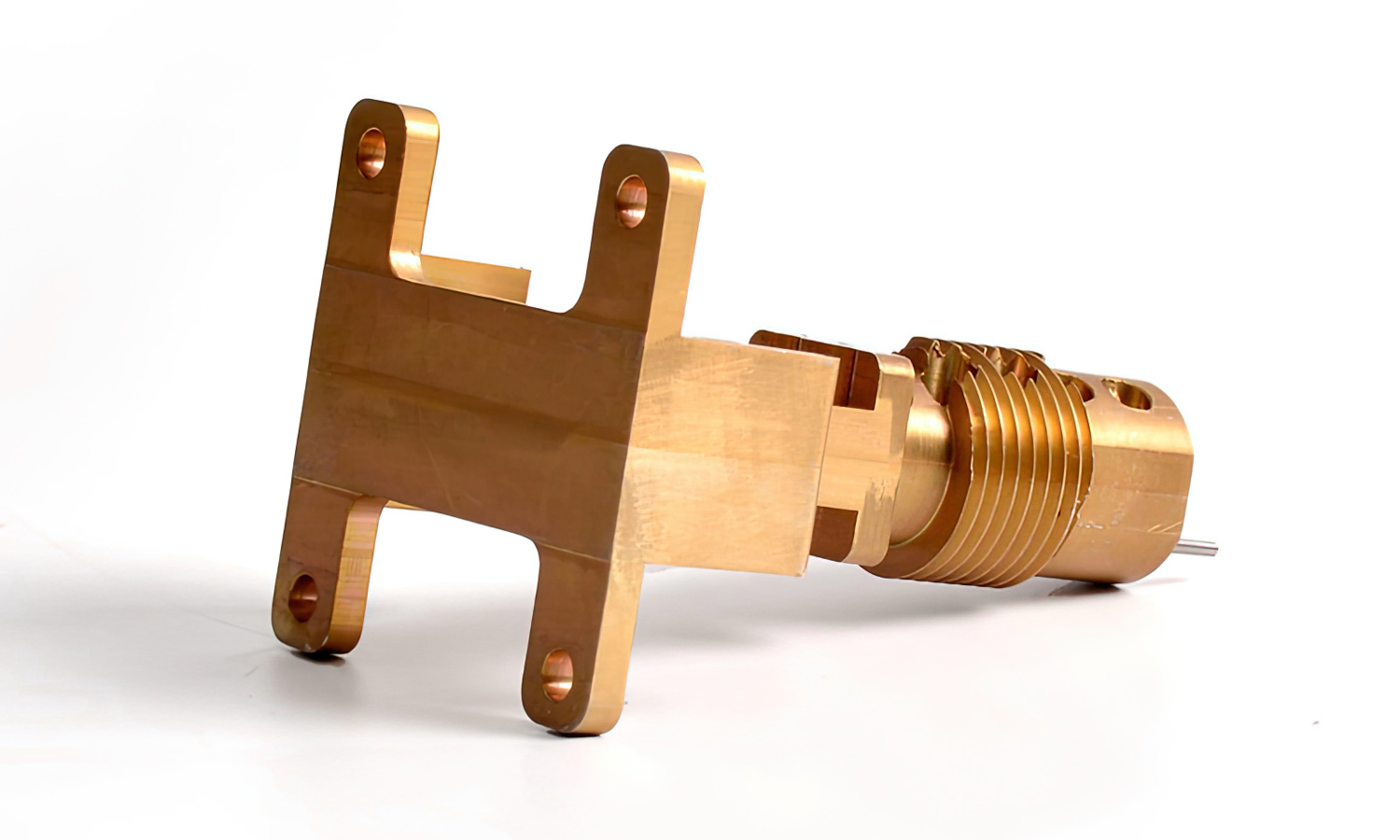

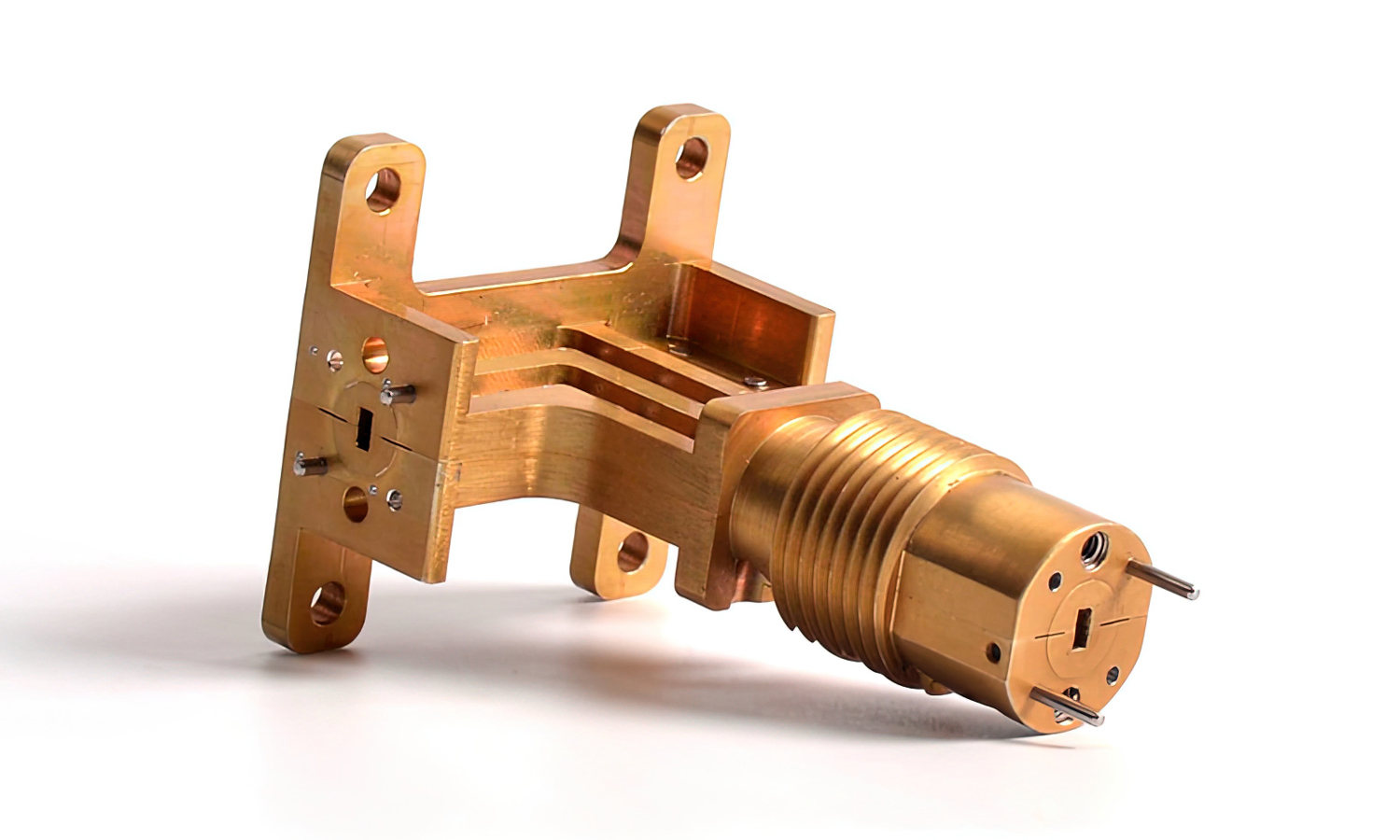

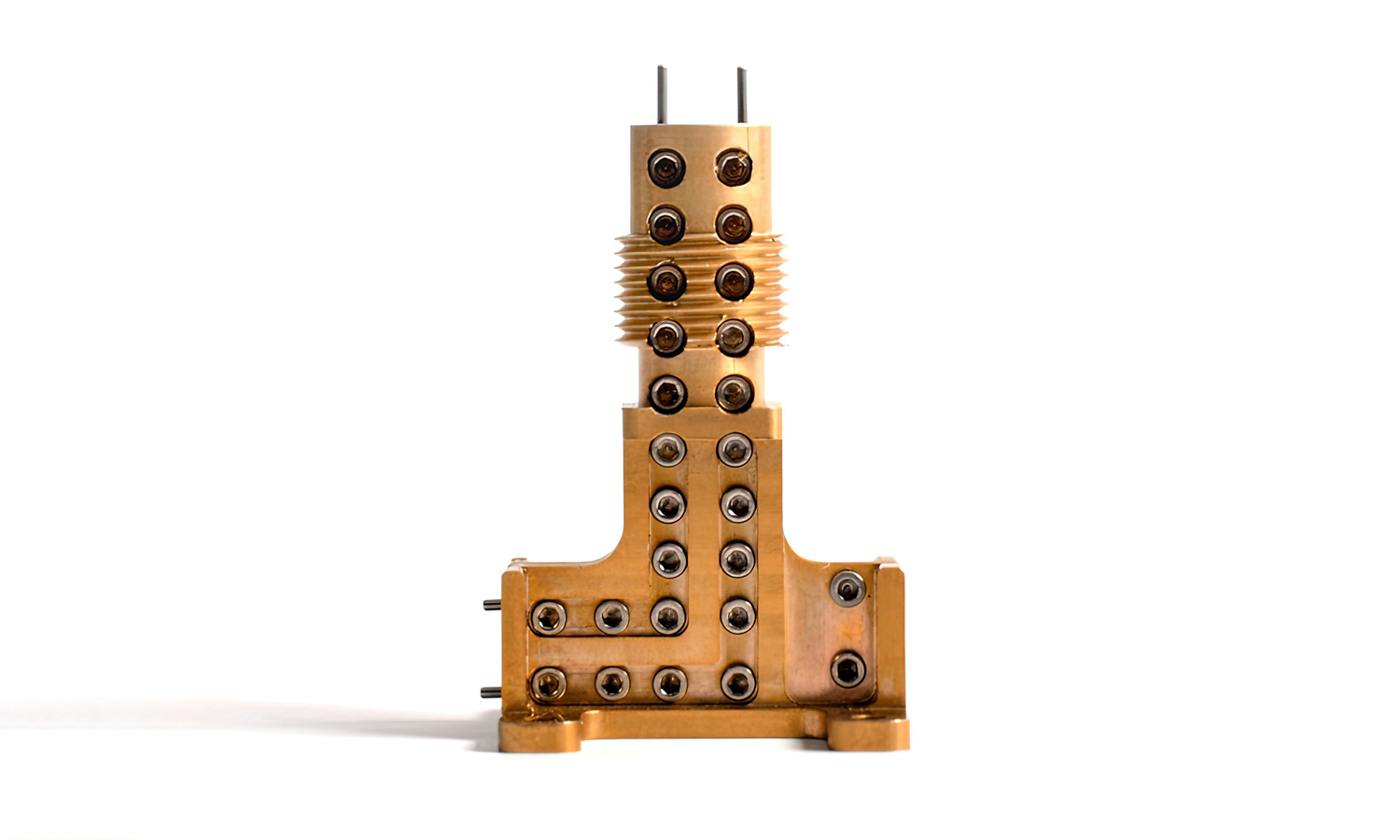

If you are looking for a versatile and durable component that can be used for various purposes, you may want to consider a CNC milled brass connector jack mount with nuts and bolts. This is a brass object that has an H-shaped base with holes on each of the four extruding ends, so it can be mounted to a surface. There are plugs on its top and side, which may be used to seal off unused ports or to connect the object to other components. Its top part is an extruding cylinder with threads on the neck, which allows the plugs to be inserted firmly. There are many holes on the object, all of which are assembled with bolts and nuts, which may be used to attach sensors, other components, or experimental samples.

One of the advantages of using a CNC-milled brass connector jack mount is that it is made of brass, which is a metal that has many desirable properties. Brass is an alloy of copper and zinc, which can also contain other metals such as lead, iron, or magnesium. Depending on the composition of brass, it can have different characteristics such as strength, hardness, corrosion resistance, malleability, and aesthetic appeal.┬ĀBrass is also highly machinable, which means it can be easily shaped and cut by CNC machines.┬ĀCNC machines are computer-controlled devices that use various tools such as drills, mills, lathes, or routers to create precise and complex shapes from raw materials.

Another benefit of using a CNC-milled brass connector jack mount is that it can be customized according to your specific needs and preferences. You can choose the size, shape, design, and finish of your brass connector jack mount. You can also add features such as logos, text, or patterns to make it more unique and attractive. You can also select the type and number of plugs, bolts, and nuts that you want to use for your brass connector jack mount. You can even design your own brass connector jack mount from scratch or modify an existing one.

If you are looking for a reliable and professional service provider that can help you create your own CNC-milled brass connector jack mount with nuts and bolts, you may want to check out FacFox. FacFox is a leading online platform that offers high-quality and affordable CNC machining services for various materials such as brass, aluminum, steel, plastic, wood, and more. FacFox has a team of experienced and skilled engineers and machinists who can handle any CNC machining project from design to delivery. FacFox also has advanced CNC machines and equipment to ensure accuracy and efficiency in producing your brass connector jack mount. Whether you need one piece or thousands of pieces, FacFox can deliver your order within a short time frame and at a competitive price.

To learn more about FacFoxŌĆÖs CNC machining services and how they can help you create your own CNC milled brass connector jack mount with nuts and bolts, you can visit their website at facfox.com. You can also contact them via email or phone to get a free quote or consultation. FacFox is your best partner for CNC machining solutions.

Solution

- Step 1: A 3D model of the brass connector jack mount was created using CAD software. The model included the dimensions, features, and specifications of the object. The model was then converted into a G-code file, which is a set of instructions for the CNC machine.

- Step 2: A brass block was selected as the raw material for the object. The brass block was clamped to the worktable of the CNC machine and aligned with the spindle axis. The CNC machine was then programmed to follow the G-code file and execute the machining operations.

- Step 3: A CNC milling tool was used to cut and shape the brass block into the desired form of the connector jack mount. The milling tool moved along the X, Y, and Z axes and removed excess material from the brass block. The milling tool also created the holes, threads, and grooves on the object.

- Step 4: A CNC turning tool was used to finish the surface of the connector jack mount. The turning tool rotated the object and smoothed out any rough edges or burrs. The turning tool also polished the object to give it a shiny appearance.

- Step 5: The CNC-milled brass connector jack mount was removed from the CNC machine and inspected for quality and accuracy. The plugs, bolts, and nuts were then inserted into the corresponding holes and tightened securely. The CNC-milled brass connector jack mount with nuts and bolts was then ready for use or delivery.