- PolyJet 3D Printed Clear Resin Klein Bottle Miniature

- SLS 3D Printed Nylon Chandelier Lighting Prototype

Gallery

About Project

Demanding unmatched precision and performance in your next mouse design? Look no further than FacFox's innovative SLM 3D-printed aluminum alloy mouse wheels!

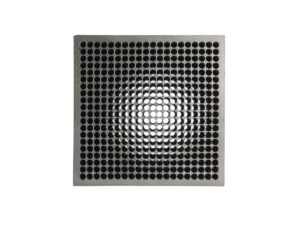

These cutting-edge wheels are crafted using Selective Laser Melting (SLM), a revolutionary 3D printing technology renowned for creating incredibly strong and lightweight metal parts. The SLM process enables intricate designs, evident in our mouse wheels' unique gear-like structure around the edges. This design element provides exceptional scrolling control, ideal for gamers, designers, and anyone seeking pixel-perfect accuracy.

But precision isn't the only advantage. The three-spoke design connecting to the central hub emphasizes these mouse wheels' unmatched durability and performance. Crafted from high-quality aluminum alloy, they can withstand even the most demanding use.

From Prototype to Innovation

These SLM 3D-printed aluminum alloy mouse wheels are a testament to FacFox's expertise in developing electronic device prototypes. We collaborated with a renowned mouse designer, a long-term partner, to bring this innovative product to life. We're eager to see what amazing new device he incorporates these wheels into!

FacFox: Powering Your Electronic Device Visions

At FacFox, we're passionate about helping entrepreneurs and businesses bring their electronic device dreams to reality. Our advanced 3D printing technologies like SLM, combined with our extensive experience, allow us to create high-fidelity prototypes that are both functional and aesthetically pleasing.

Ready to revolutionize your electronic device design?

Contact FacFox today and see how our SLM 3D printing services can propel you to unparalleled precision, performance, and durability. Let's turn your innovative ideas into reality!

Solution

- Step 1: Design & 3D Modeling. The process begins with a detailed 3D model of the mouse wheel, designed for precise scrolling control and durability. The gear-like structure and three-spoke design are meticulously crafted in the CAD software.

- Step 2: Slicing. The 3D model is then sliced into thin horizontal layers, preparing it for the SLM printer.

- Step 3: Printing Setup. A high-power laser is used to selectively fuse aluminum alloy powder. The printer spreads a thin layer of this powder onto the build platform.

- Step 4: Layering. The laser sinters the powder according to the cross-section of the design, layer by layer, until the wheel takes shape.

- Step 5: Cooling & Removal. After printing, the build chamber is allowed to cool before the wheels are removed. Excess powder is cleaned off, revealing the raw, unpolished mouse wheel.

- Step 6: Post-Processing. Although these specific wheels did not undergo fine polishing, typically, post-processing include stress-relief through heat treatment and surface smoothing.