- SLM 3D Printed Aluminum Alloy Mouse Wheels

- CNC Milled Copper and Alumnium Earbuds Enclosure Prototype

Gallery

About Project

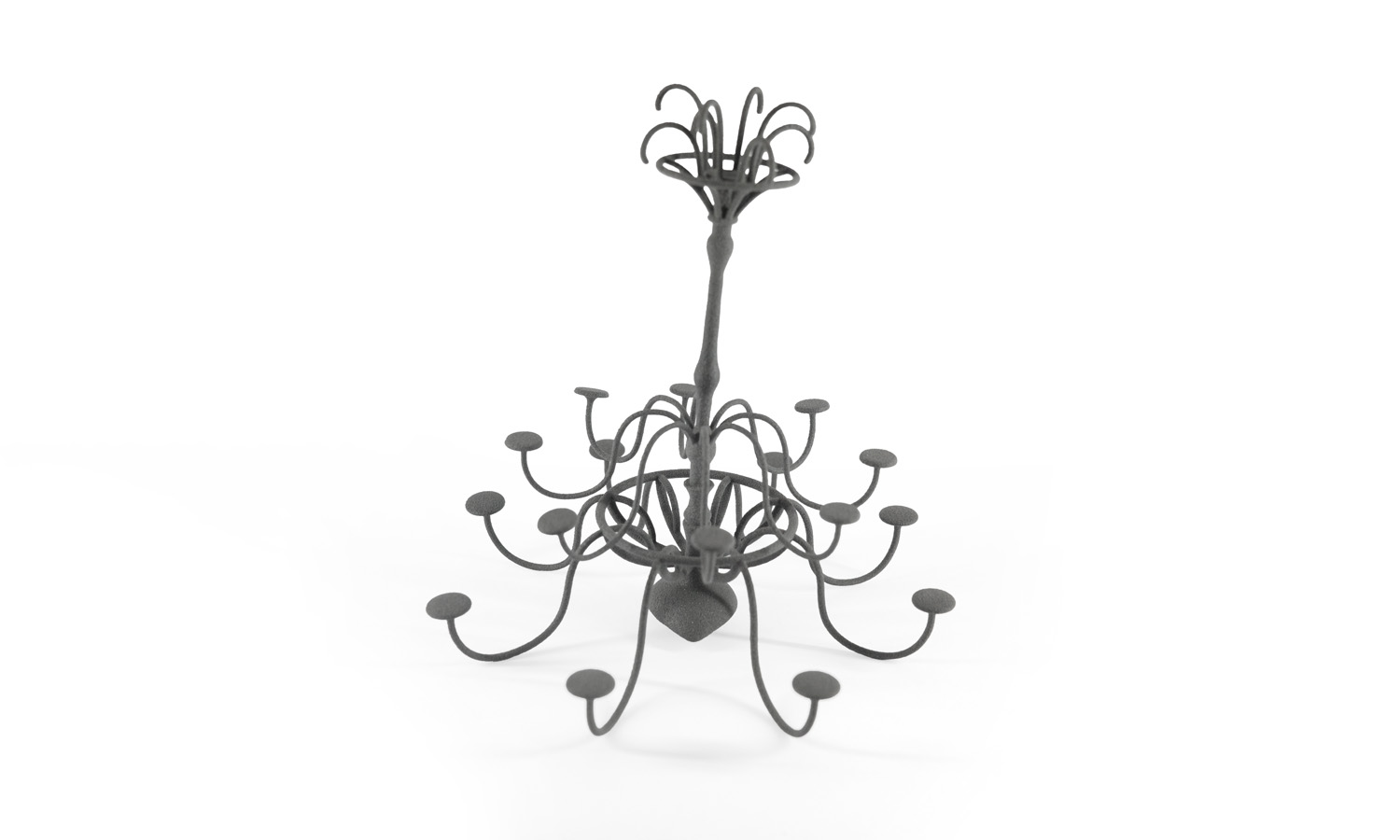

Imagine a chandelier that seamlessly blends the timeless beauty of swirling curves with the magic of cutting-edge technology. Look no further! This exquisite prototype, crafted from SLS 3D printed nylon, embodies both classic design and modern innovation.

A Dance of Light and Form

The chandelier boasts an elegant and classic design, featuring curvilinear elements that dance across its form. Its intricate details are meticulously brought to life through SLS 3D printing, renowned for its ability to produce highly complex shapes with stunning accuracy.

Strength Meets Lightness

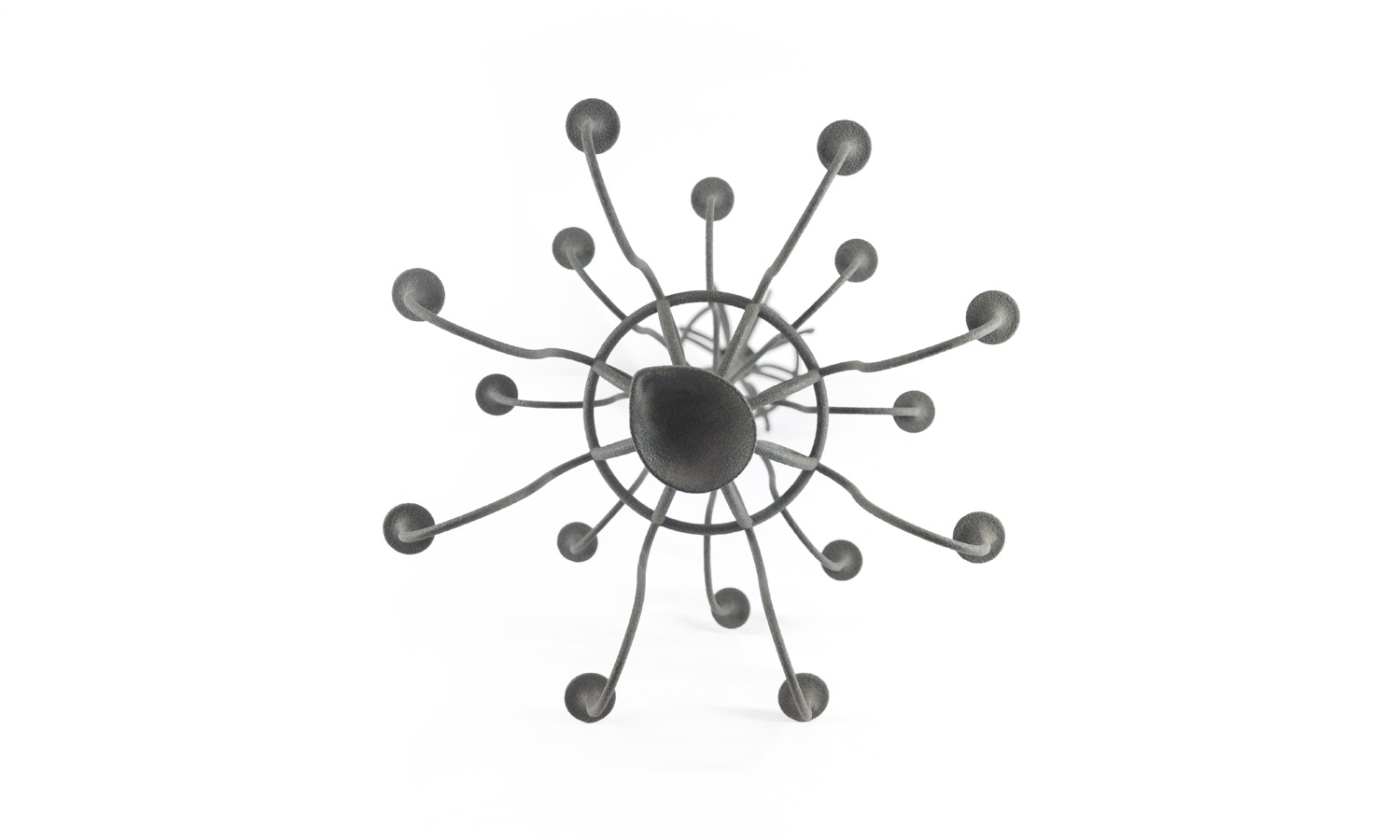

This masterpiece is meticulously 3D printed using nylon powder, resulting in a structure that is both durable and lightweight. Multiple arms extend symmetrically from a central base, culminating in circular holders – perfect for showcasing candles or light bulbs. To emphasize the raw beauty of the design, the prototype features a default post-processing finish, highlighting the inherent texture of the 3D-printed nylon.

Limitless Potential for Illumination

This stunning chandelier prototype exemplifies the limitless potential of SLS 3D printing for creating intricate lighting fixtures. At FacFox, we specialize in nylon prototyping services, providing exceptional support for designers and manufacturers seeking to bring their complex lighting concepts to life.

FacFox: Illuminating Your Lighting Vision

Our SLS 3D printing expertise empowers you to:

- Achieve intricate designs with unmatched precision

- Leverage the strength and durability of nylon

- Explore various post-processing options to achieve your desired aesthetic

FacFox is your one-stop shop for transforming your visionary lighting designs into reality. Contact us today to discuss your SLS 3D printing needs and illuminate the path to success for your next lighting project.

Solution

- Step 1: Design and File Preparation.┬ĀThe chandelier is designed using SolidWorks software, ensuring that the model can be printed in one piece without the need for assembly. The design incorporates elegant and classic elements with curvilinear forms and swirls. The final design is then exported in an STL file.

- Step 2: Printer Preparation.┬ĀThe SLS printer is prepared by calibrating the machine and filling the print bed with SLS nylon powder.

- Step 3: Printing Process.┬ĀThe printer heats the nylon powder to just below its melting point. A laser selectively sinters the powder, solidifying the chandelierŌĆÖs design layer by layer. After each layer is sintered, the print bed lowers, and a new layer of powder is spread on top. This process repeats until the chandelier is fully printed as a single piece.

- Step 4: Cooling.┬ĀThe build chamber and the printed chandelier are allowed to cool down gradually to room temperature to prevent any deformation.

- Step 5: Part Extraction and Cleaning.┬ĀThe chandelier is carefully extracted from the powder bed. Excess nylon powder is removed using brushes and compressed air.

- Step 6: Post-Processing.┬ĀSince the chandelier is intended to have a raw finish, the default post-processing involves minimal steps, just a light blasting to remove any remaining loose powder and ensure a consistent surface.

- Step 7: Quality Check.┬ĀThe chandelier undergoes a quality inspection to ensure it meets the design specifications and has no defects.