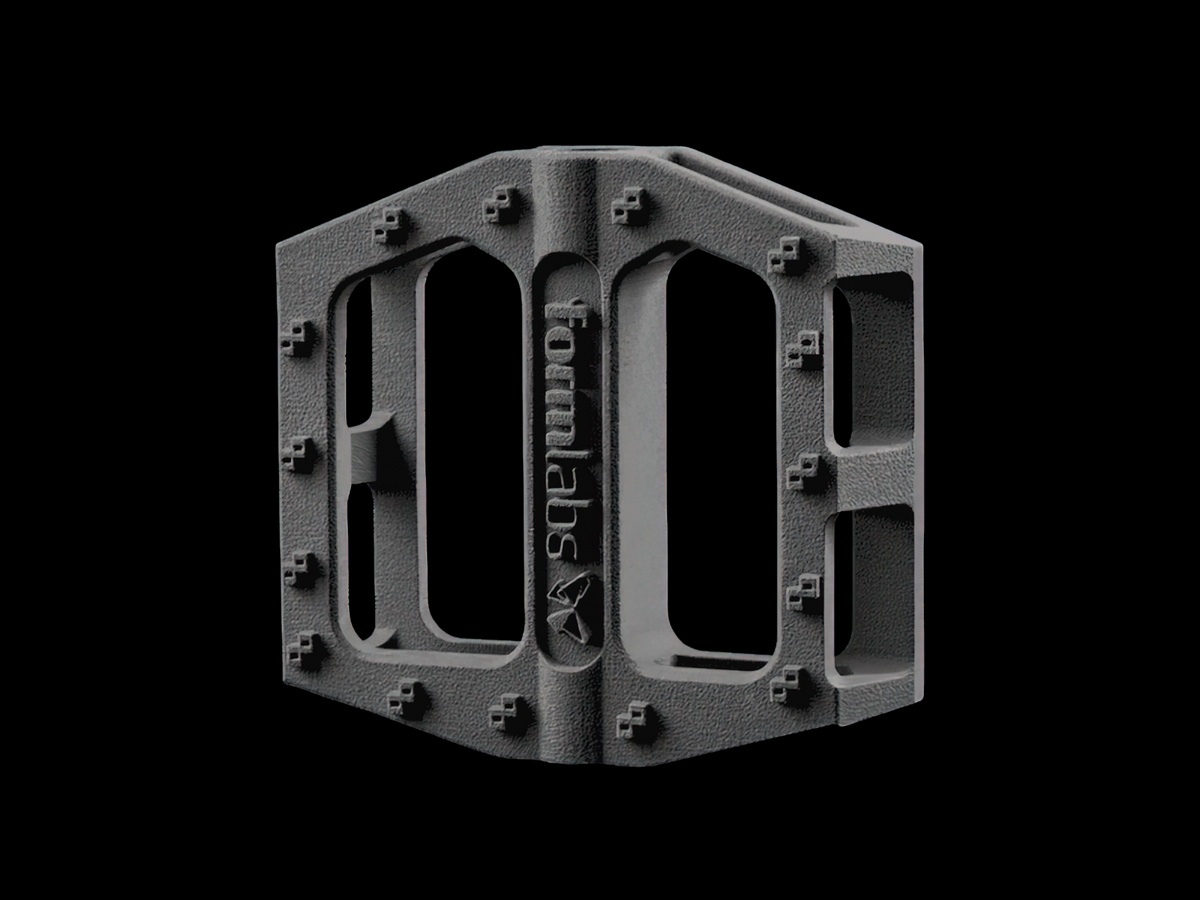

SLS Formlabs Nylon PA12Formlabs Nylon PA12 Balancing strength and detail, Nylon 12 is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability. Max Build Size Min Build Size 10 x 10 x 10 mm Default Layer Height 0.11 mm Optional Layer Heights 0.11 mm Tolerance ┬▒0.3% (with a lower limit of ┬▒0.3 mm) Up to 87 Ōäā Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģŌśģŌśģ Available ColorsGrey

Available Post ProcessPaint

, Dyeing

, Sandblast

Suitable For Functional prototypes and end products, Not Suitable ForAdditional Info

Feature

3D PrinterMaterial Spec Sheet

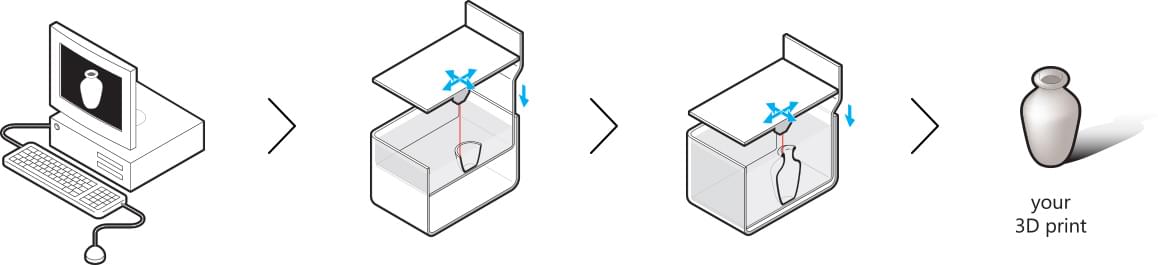

Laser sintering is used to build your design with this material. The models are printed layer by layer by a laser that draws thin lines in the powder, which melts and bonds it together in order to form a thin layer of the model. After a layer is printed, a new layer of fresh powder is spread over the surface by a roller. The printer has a print chamber that is heated to just below the melting point of the powder; the laser beam adds the extra energy to melt the powder, forming a solid model. After a print job is finished, the result is a big block of heated powder with the printed models contained inside.

|