SLM Aluminum AlSi10MgAlSi10Mg Parts in EOS Aluminium AlSi10Mg are ideal for applications which require a combination of good thermal properties and low weight. They can be machined, spark-eroded, welded, micro shot-peened, polished and coated if required. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.04 mm Optional Layer Heights 0.05, 0.1 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) N/A Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģŌśģŌśģ Flexibility ŌśģŌśģ Available ColorsMetal

Available Post ProcessPolish

, Sandblast

, Anodize

, Electroplate

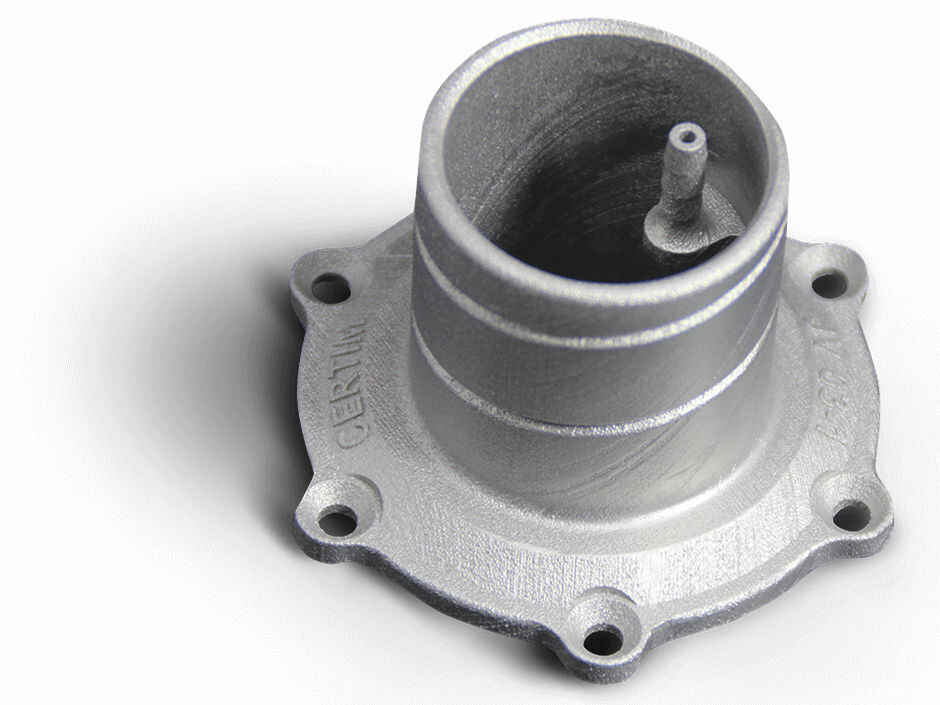

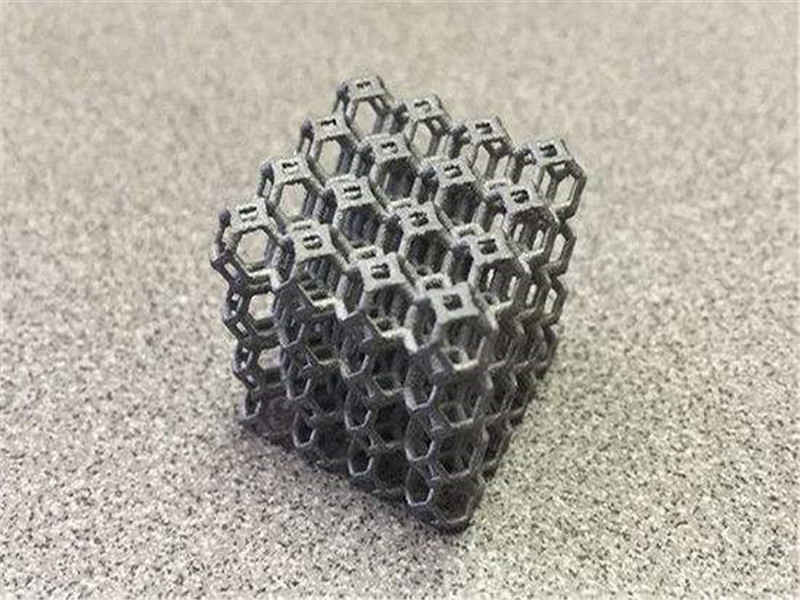

Suitable For Functional prototypes and end products, Not Suitable For Fine-detail models with smooth surfaces, Additional InfoThe pricing for Aluminum is based on: – Model volume: The volume of your model is used to calculate the material cost (mm┬│) – The box around your model: An imaginary box around your model determines how much space your design will take up in the printer (X * Y * Z = mm┬│) – Model surface For Aluminum, we charge a minimum price per ordered piece. Unlike the startup cost (which is applied to most materials), this cost vanishes when the price is higher than the minimum price. Aluminum (AlSi10Mg) is a strong, low weight material with good thermal properties. ItŌĆÖs printed by sintering aluminum powder together with a laser to produce metal parts that are equally as good as machined models. 3D-printed aluminum doesnŌĆÖt look like traditional shiny milled aluminum. Instead, it has a matte gray finish with a slightly rougher and less defined surface. The subtle sparkle youŌĆÖll notice is caused by the presence of silicon in the alloy. Aluminum is suitable for strong, light and precise metal parts. Applications range from spare parts to components of RC cars, gadgets, and even jewelry.

Feature

3D PrinterMaterial Spec Sheet

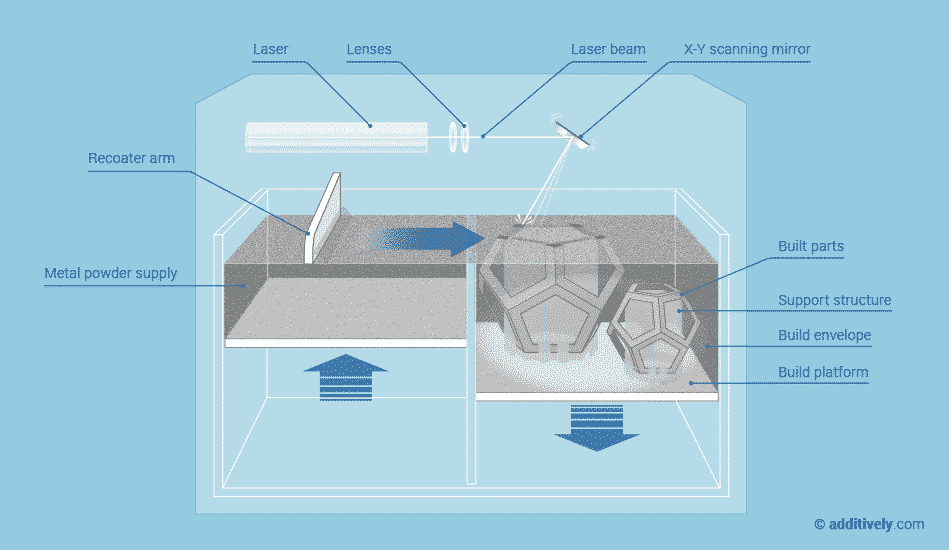

Selective Laser Melting creates objects from thin layers of powdered material by selectively melting it using a high power laser. The process takes place in a low oxygen environment in order to reduce thermal stresses and to prevent warping. Industrial metals are best used for high-tech, low-volume use cases from prototyping to creating end-use parts. Metal 3D prints are comparable to traditionally manufactured parts in terms of chemical composition, mechanical properties (static and fatigue) as well as microstructure. Once the printing is done, the extra powder that was not bound, and is not part of your design, is removed. Your part is now solid metal, and after the flutes are manually removed, it is tumbled and polished to produce a smooth finish.

|