- CNC Milled Brass Connector Jack Mount with Nuts and Bolts

- CNC Turned SS316L Orifice Extension with Threading Connection

Gallery

About Project

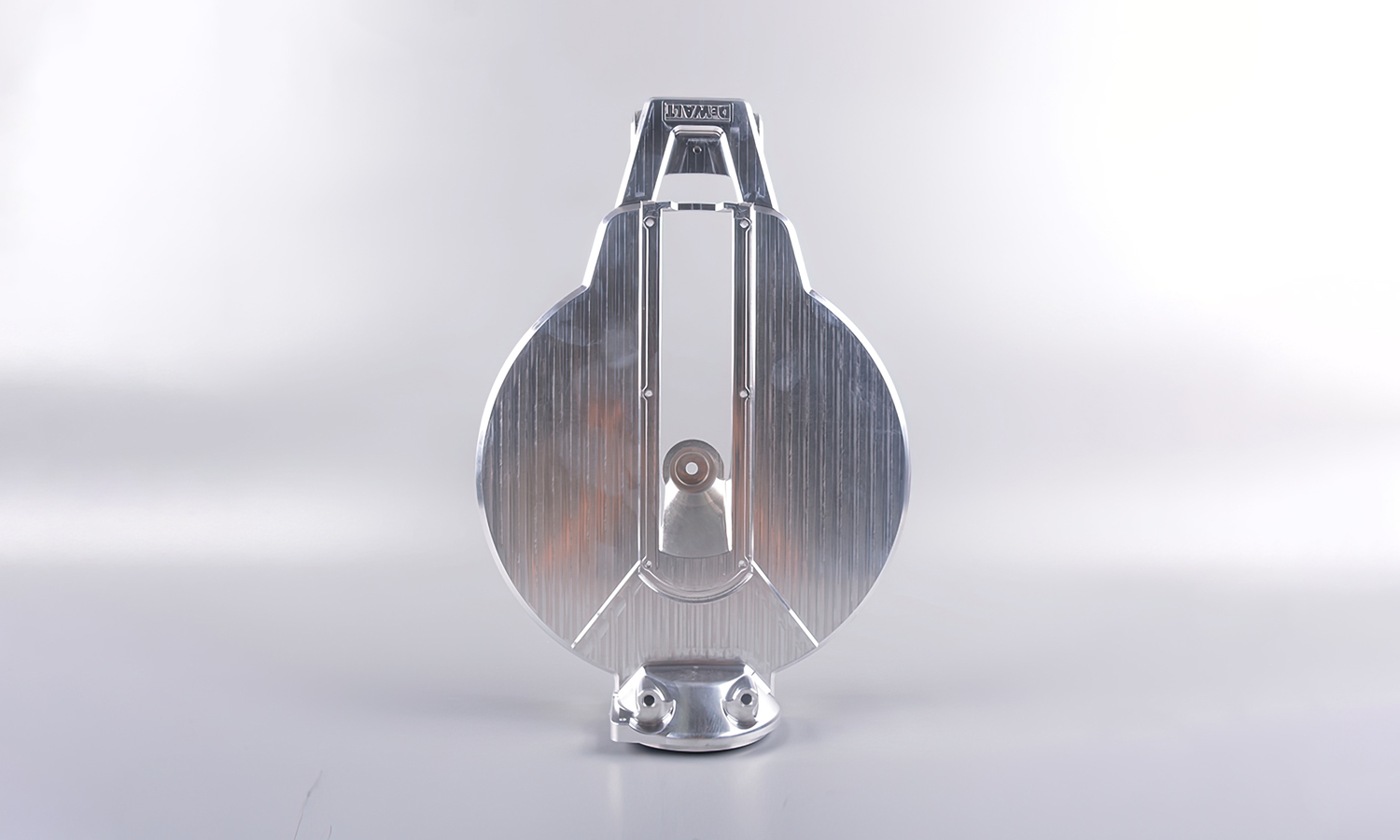

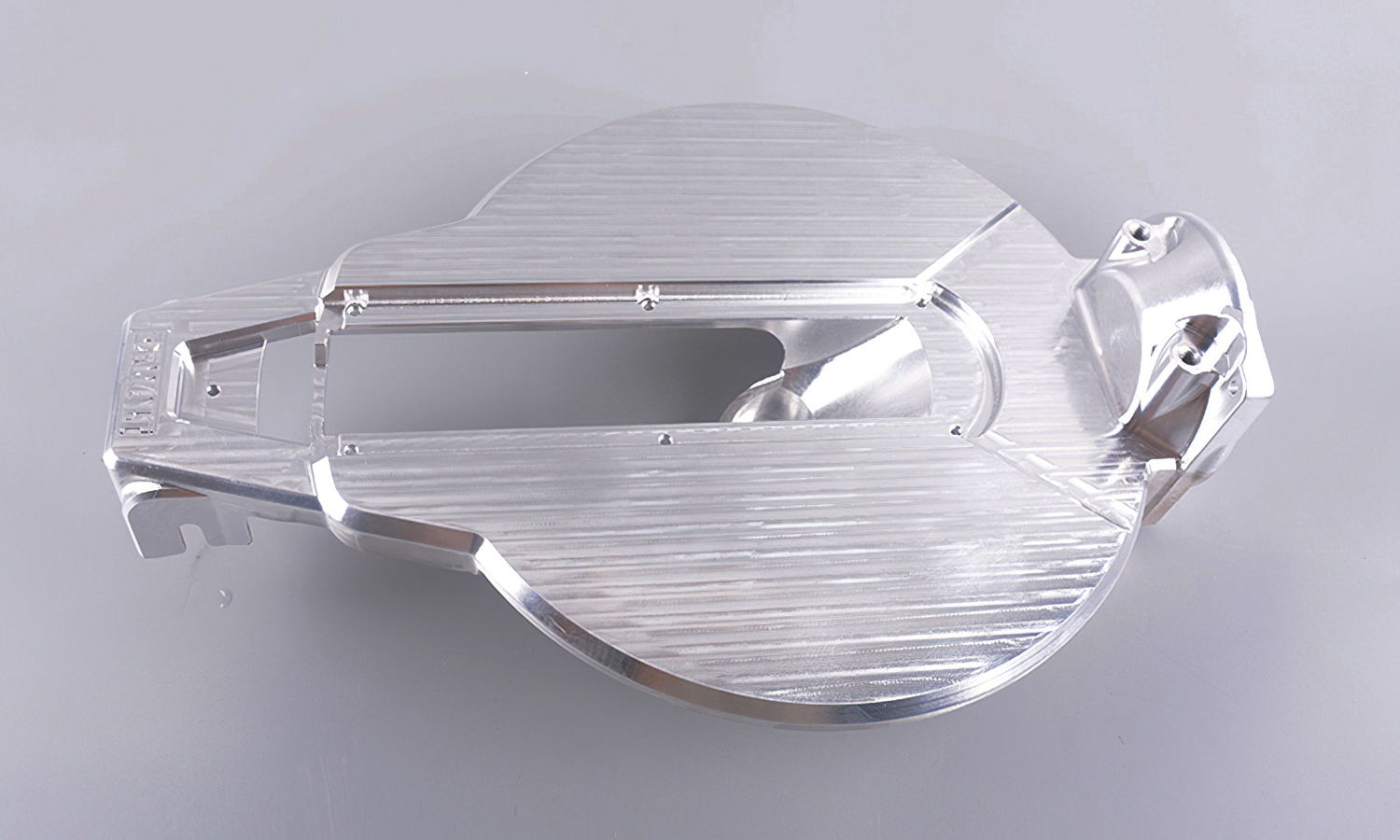

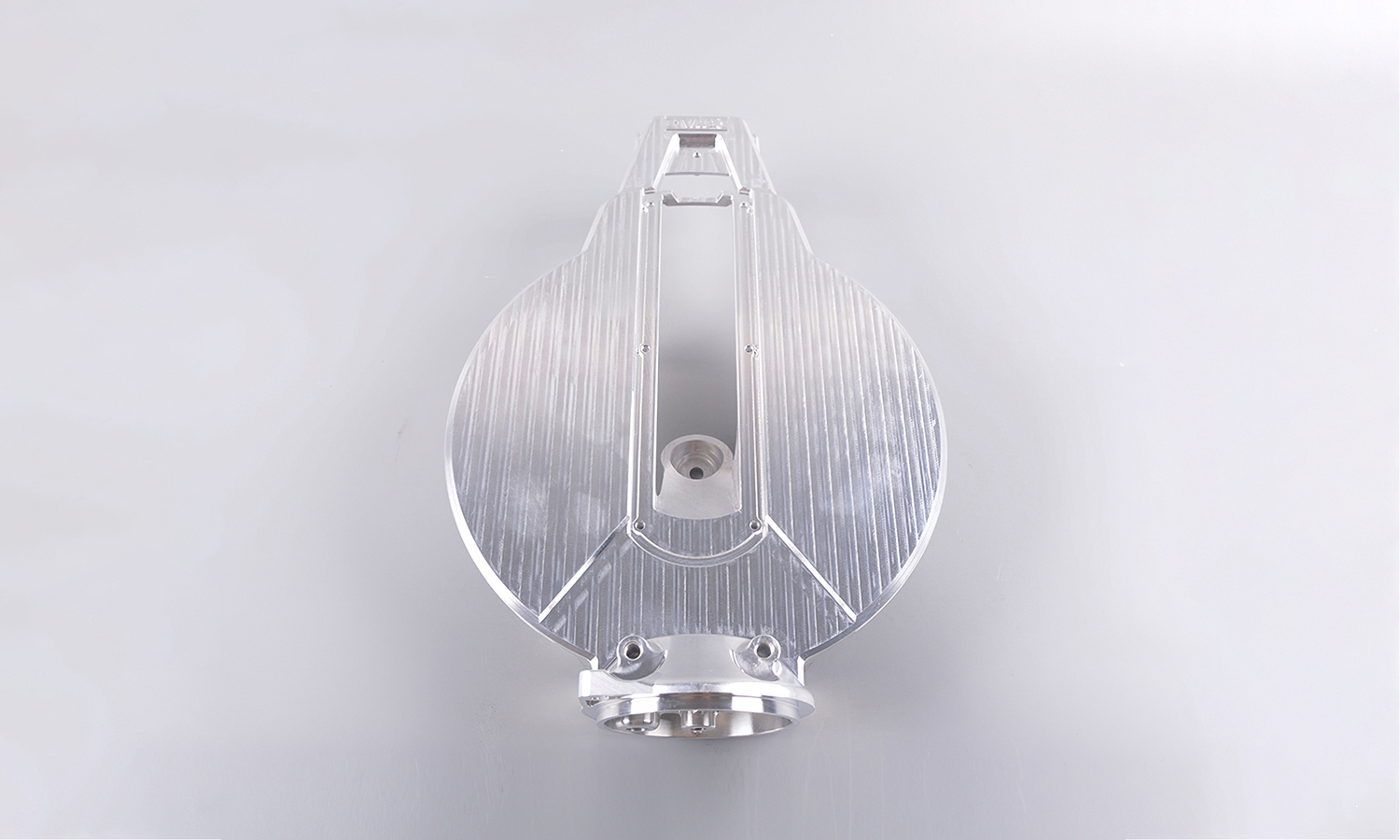

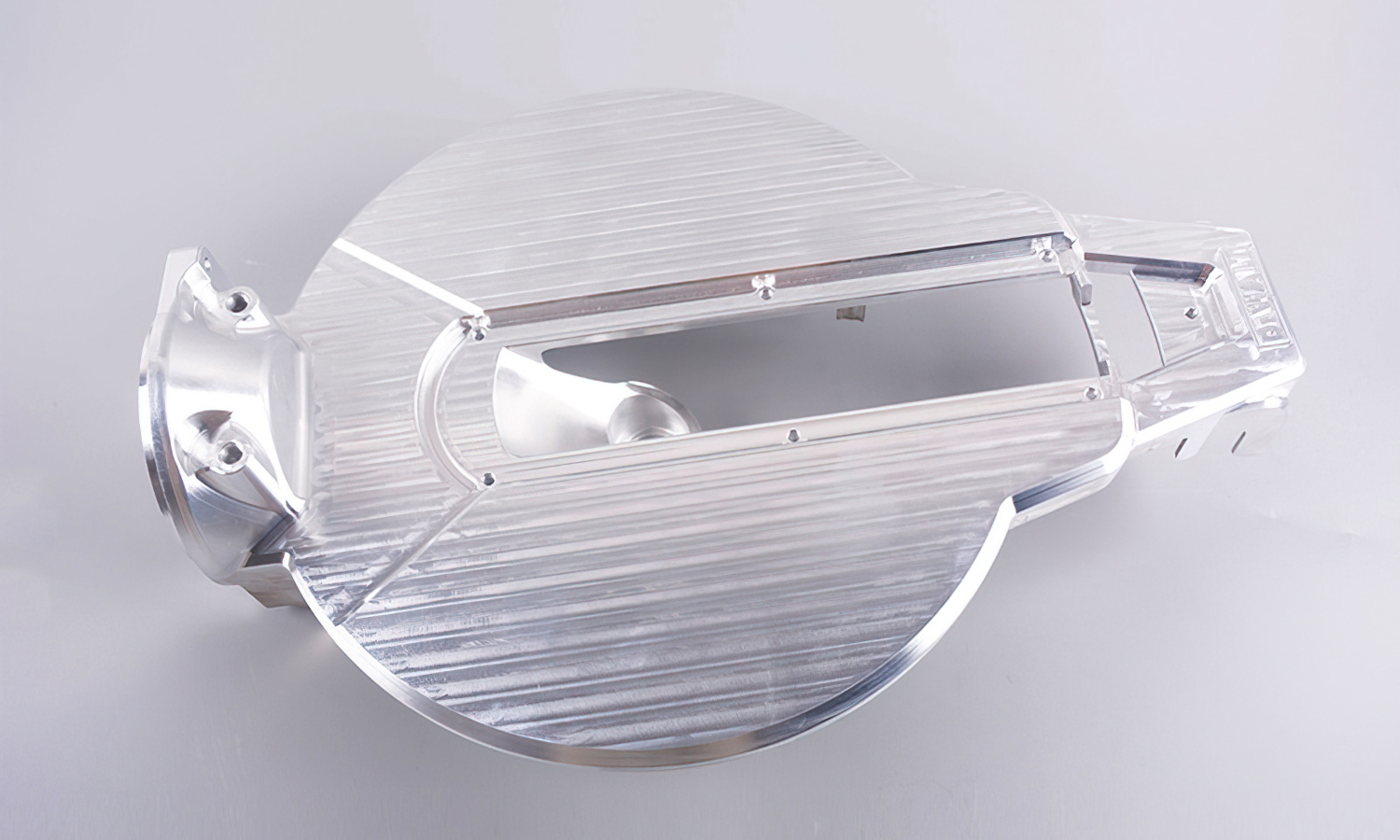

If you are looking for a way to improve the accuracy and safety of your table saw, you might want to consider getting a CNC Milled Die Steel Table Saw Zero Clearance Insert. This is a circular metal plate that replaces the original insert that comes with your table saw. It has several advantages over the standard insert, such as:

It reduces the amount of tear-out and splintering on the cut edges of your workpiece, resulting in a smoother and cleaner finish.

It prevents small pieces of wood from falling into the gap between the blade and the table, which can cause kickback and damage your saw or injure you.

It supports the workpiece better and reduces the risk of it bending or flexing during the cut, especially when cutting thin or narrow materials.

It improves the dust collection efficiency of your table saw, as less dust and debris escape from the gap.

This CNC Milled Die Steel Table Saw Zero Clearance Insert is made from high-quality die steel, which is a type of tool steel that has high hardness and wear resistance. It can withstand the heat and friction generated by the saw blade, and last longer than other materials. CNC milling is a process that uses computer-controlled machines to cut and shape metal with high precision and accuracy. CNC milling ensures that the insert fits perfectly into your table saw top, and has a smooth and flat surface.

The insert has a hole in the center that is slightly larger than the diameter of your saw blade, so that the blade can freely rotate. The hole also has a raised lip around the edge, which helps to support the workpiece and prevents it from slipping down into the blade. The insert has a flange on one side that fits into a slot on the table saw top. The flange helps to keep the insert in place and prevents it from moving around during use.

To install the insert, you need to remove the original insert from your table saw, and replace it with the CNC Milled Die Steel Table Saw Zero Clearance Insert. You need to adjust the height of your saw blade so that it barely touches the surface of the insert. Then, you need to turn on your saw and slowly raise the blade until it cuts through the insert, creating a zero clearance slot that matches your blade exactly. You can then lower the blade to your desired cutting height, and start using your table saw as usual.

If you are interested in getting a CNC Milled Die Steel Table Saw Zero Clearance Insert for your table saw, you can order one from FacFox, a leading online platform for custom manufacturing services. FacFox can provide you with high-quality CNC milling services at affordable prices and fast delivery times. You can upload your design file to facfox.com or choose from their existing models, and get an instant quote for your order. FacFox also offers other services such as 3D printing, injection molding, sheet metal fabrication, and more. Visit their website today and see how they can help you with your project needs.

Solution

- Step 1: A circular metal plate was cut from a sheet of die steel, which was a type of tool steel that had high hardness and wear resistance.

- Step 2: The plate was clamped onto a CNC milling machine, which was a computer-controlled machine that could cut and shape metal with high precision and accuracy.

- Step 3: The machine followed a design file that specified the dimensions and shape of the insert, including the hole, the flange, and the lip.

- Step 4: The machine used a rotating cutting tool called a mill to remove excess material from the plate, creating the desired features of the insert.

- Step 5: The machine also smoothed and polished the surface of the insert, making it flat and even.

- Step 6: The insert was then removed from the machine and inspected for quality and accuracy.