- SLM 3D Printed Aluminum 6061 Rear Suspension System Automotive

- SLM 3D Print Aluminum Sample with Default Polishing Finishing

Material Resin

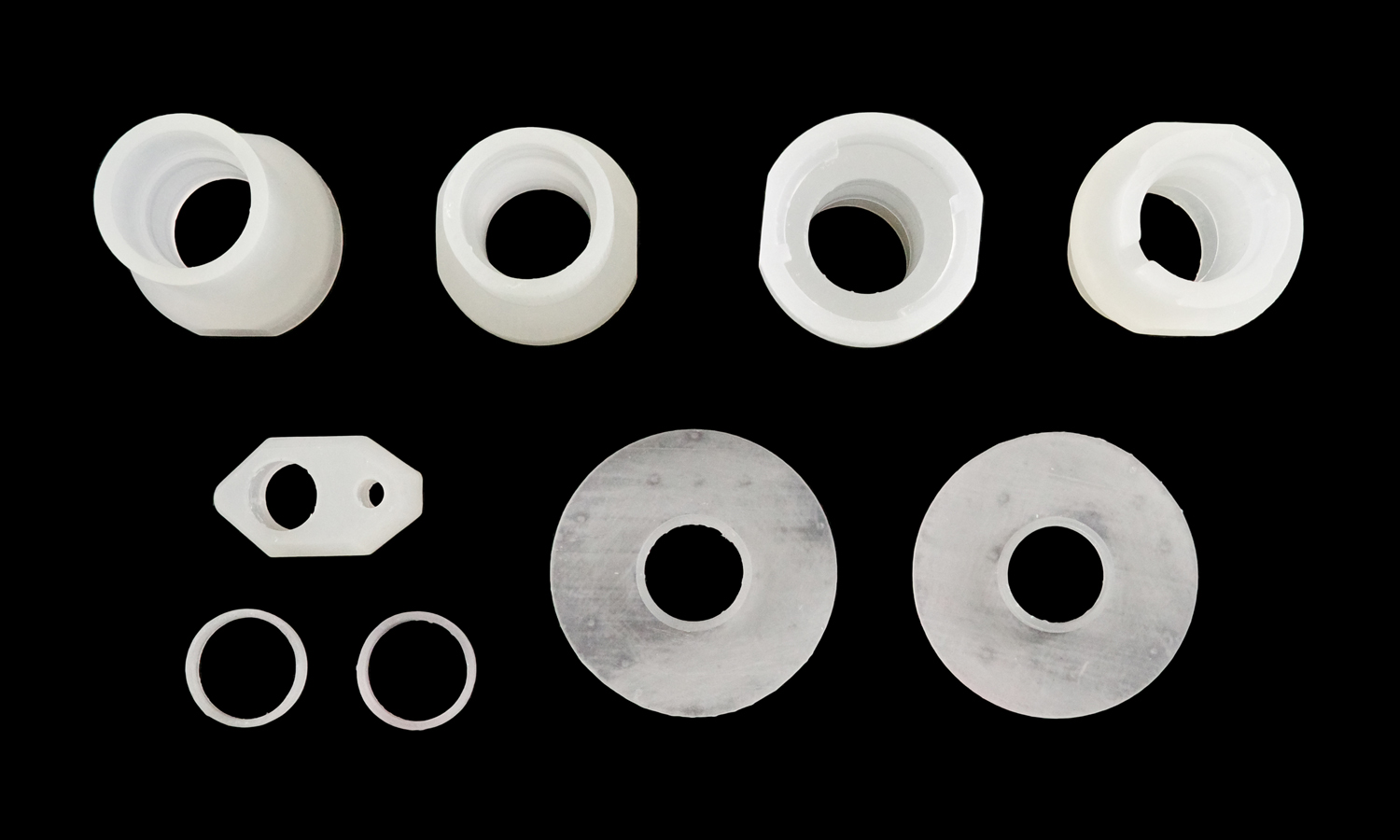

Quantity 9 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

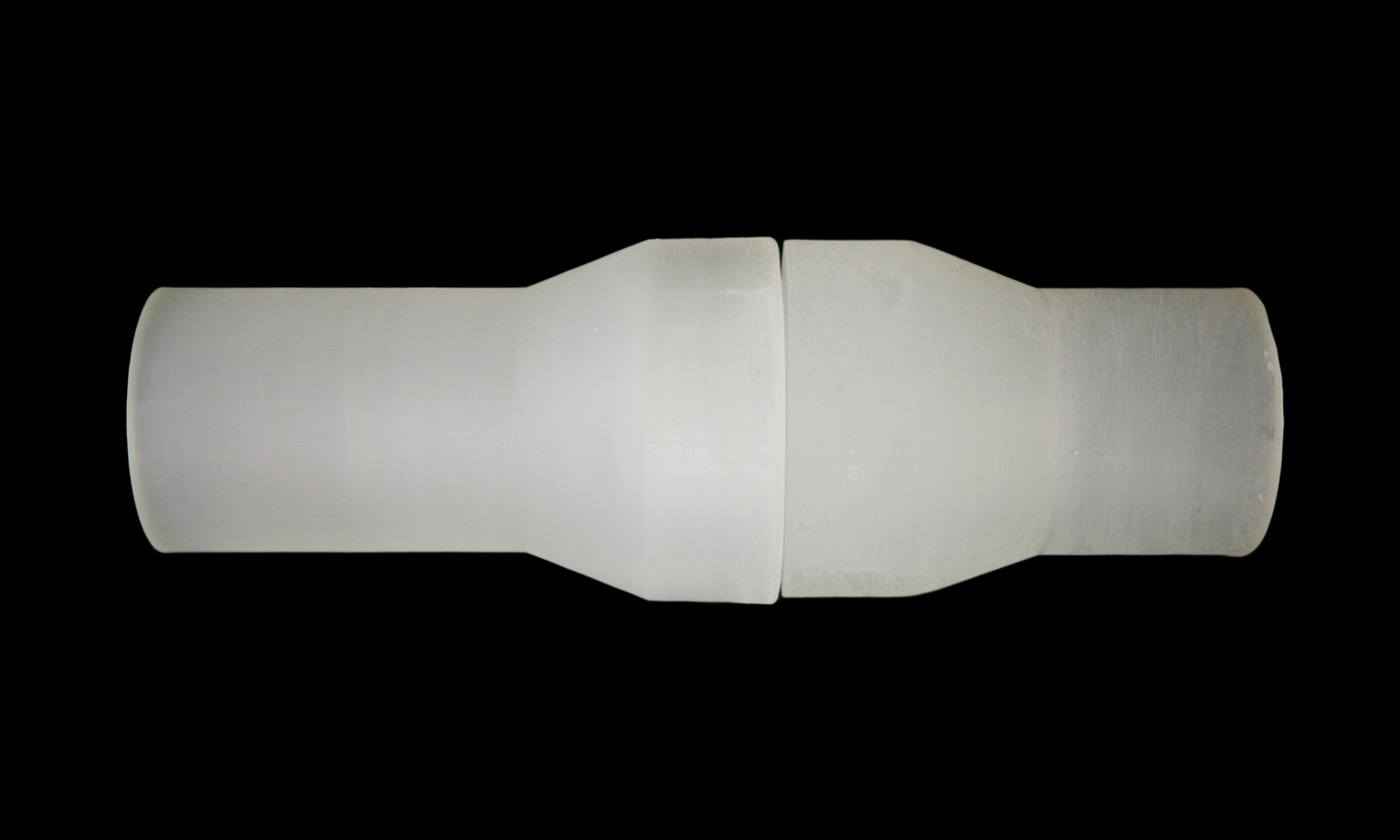

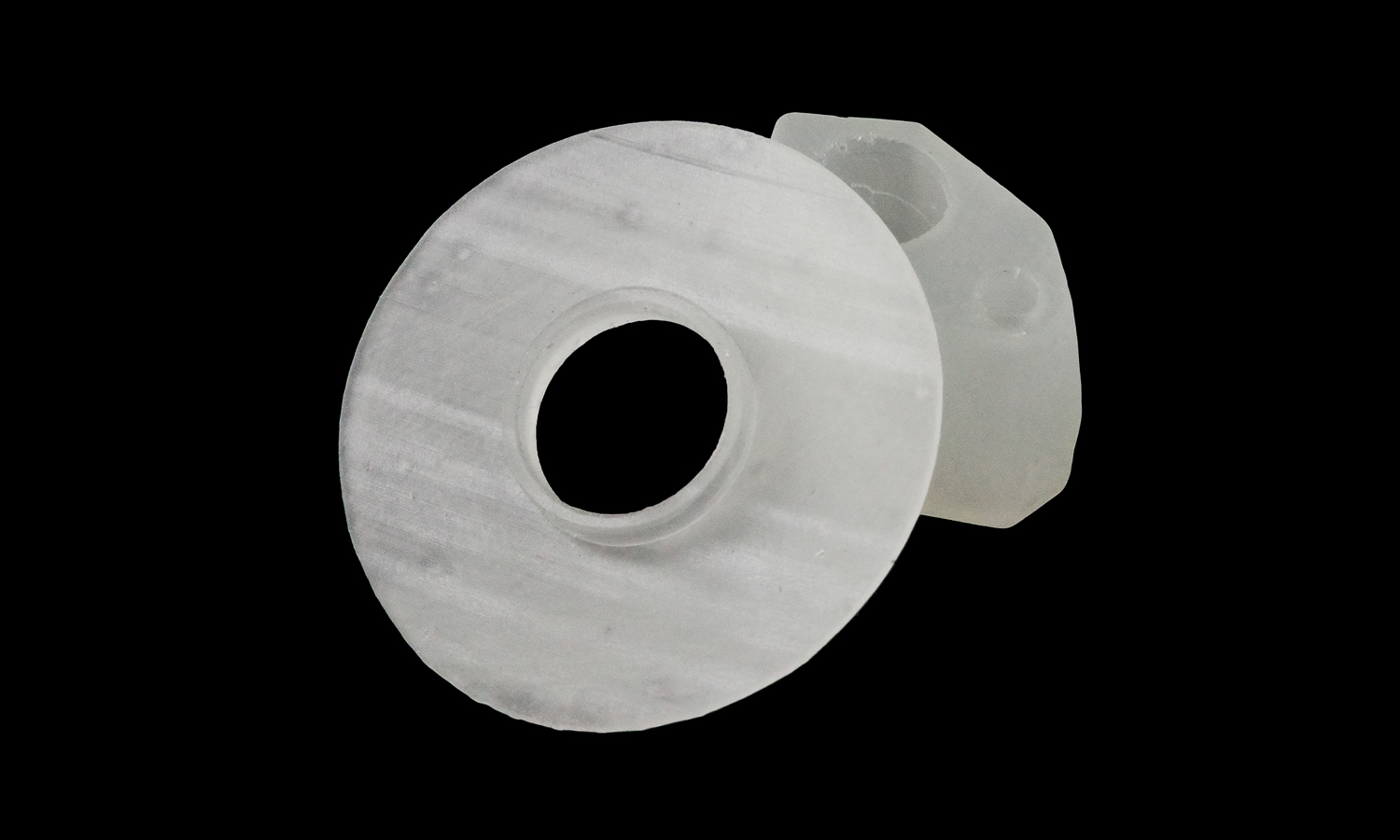

If you need to create prototypes of tubes and tube connectors that fit together perfectly, you might want to check out our latest custom 3D printing project. We used SLA 3D printing technology and Formlabs Durable Resin to print prototypes of tubes and tube connectors that are durable, translucent and resistant to wear and tear.

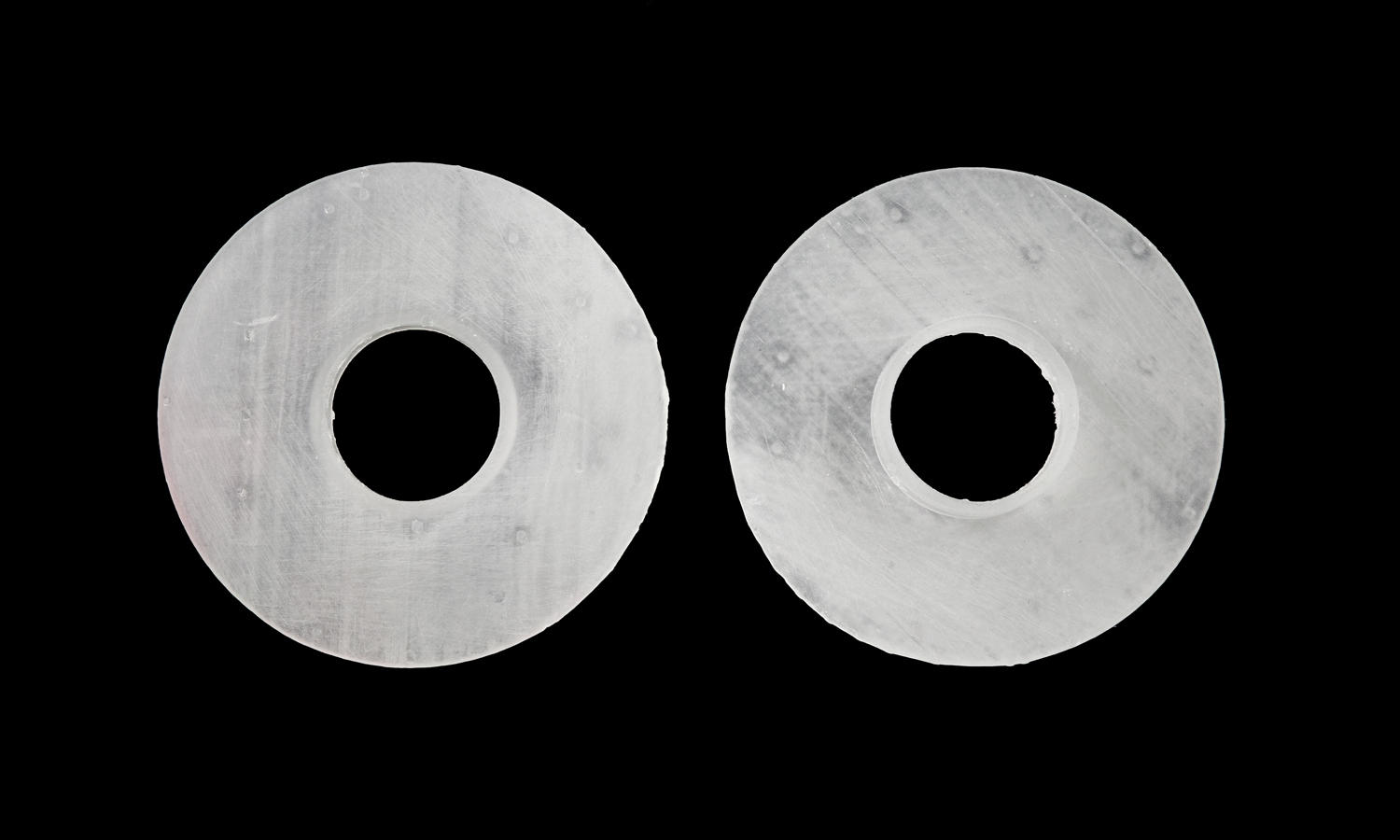

SLA 3D printing uses a laser to cure liquid resin into solid layers, creating high-resolution and smooth-surfaced parts. Formlabs Durable Resin is an engineering resin that simulates polypropylene, a common thermoplastic used for low-friction and low-wear applications. The prints had a consistent wall thickness and a frosted clear appearance, and the male tube fitted well with the female tube.

We were very happy with the results of this project, as it showed the potential of SLA 3D printing and Formlabs Durable Resin. If you want to try this technology for your own projects, you can contact us at FacFox, a professional online 3D printing service provider.

Solution

- Step 1: 3D models were thoroughly examined to make sure the minimum details were large enough, and a quote was given based on the quantity, material, etc.

- Step 2: The positioning of the models was arranged on the platform in the software. In the meantime, supporting structures were added to the model.

- Step 3: The models got 3D printed with the material SLA Formlabs Durable Resin and Form 3+ desktop SLA 3D printer.

- Step 4: When printing was finished, the parts were rinsed with IPA and post-cured with UV. Then the supporting structures were removed with the help of pliers and scissors.

- Step 5: The parts were polished with fine-grit sandpaper to get rid of the remaining marks.