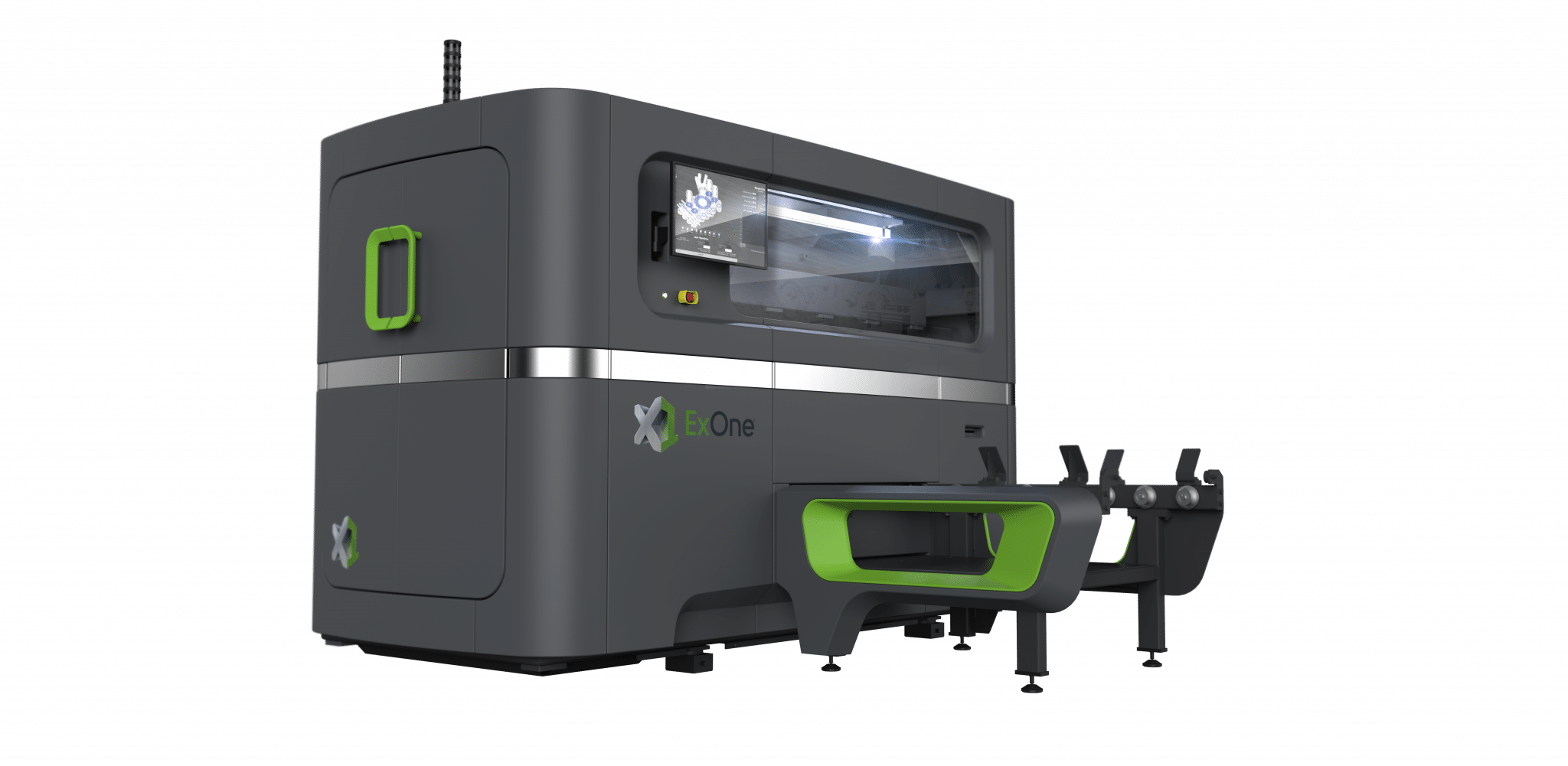

SSI Sintered Specialties, a leading metallurgical solutions partner, has purchased the X1 160Pro and InnoventPro 3L metal binder jetting system from ExOne. The AM systems feature ExOne’s patented Triple Advanced Compaction Technology (ACT), developed to implement volume production.

The deal is of particular significance as SSI markets itself as a – among other things — a high volume manufacturer for verticals such as automotive, medical and other large industrial application areas, which marks a departure from the typical adopters of AM specializing in low volume manufacturing, tooling and prototyping. This is exactly the promise of metal binder jetting and this deal takes ExOne (and its mother company Desktop Metal) one step closer to achieving it. The X1 160 is ExOne’s largest production 3D printer and was built to deliver on volume production with metal binder jetting.

The two ExOne printers are slated for delivery in the first half of 2022 and will be located at the company’s Headquarters in Janesville, WI. SSI’s 250,000 square foot facility also houses the world’s largest installed capacity of high-temperature sintering furnaces — a process step core to metal binder jetting – and post-processing technology to support volume production in metal binder jetting.

Manufacturing on Demand

“The addition of metal binder jetting to SSI’s technology portfolio was the natural next step in providing our customers with the most advanced technology on the market to produce complex geometries in volume production,” said Paul Hauck, SSI Sintered Specialties COO. “Our expertise and lengthy heritage in high-temperature metallurgy processing is a perfect fit for binder jetting technology, and we are thrilled to be working with ExOne to offer our customers the future of metal 3D printing.”

SSI has over 40 years of powder metallurgy experience and metal 3D printing adds to the company’s existing capabilities in Press and Sinter powder metallurgy and nontraditional Metal Injection Molding. With ExOne’ 3D printers and SSI’s sintering capabilities, the parts manufacturer will offer components with increased complexity and size for volume production with no tooling in a variety of metals.

The investment in ExOne’s binder jet technology is just one of the steps in SSI’s business strategy to embrace additive manufacturing and bring new manufacturing solutions for volume production.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment