3DEO Adds DfAM as Core Service

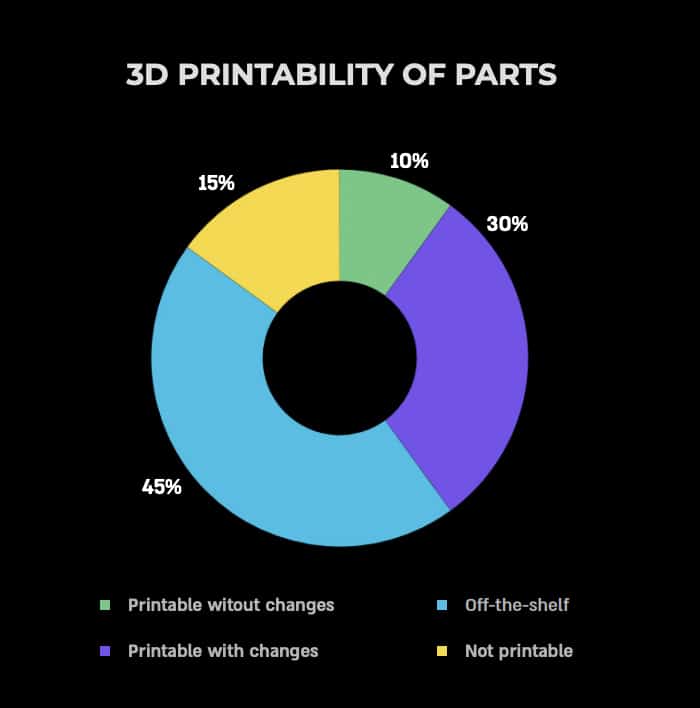

Los Angeles-based 3DEO, one of the world’s highest volume metal 3D printing companies, has added design and engineering services to its portfolio of offerings, to better support its customers throughout the entire product lifecycle. 3DEO is introducing advanced end-to-end solutions to product and engineering teams across all industries, specializing in medical devices, industrial equipment, aerospace and consumer products. The decision to include early-stage DfAM in its already differentiated 3D printing technology service gives 3DEO a further advantage to uniquely solve its customers’ needs at any stage of the product development lifecycle – with the ultimate goal of production at scale.