Materials are the cornerstone of additive manufacturing as they can truly make the difference when it comes to applications. Having materials with superior physical properties is what has allowed additive manufacturing to be increasingly used for end-use applications, whether they be plastics, composites, metals or one of the many new innovative materials being used in 3D printing, such as food or cells. In this ranking, we are taking a closer look at some of the most innovative materials that we have seen in Formnext 2021. We focus especially on polymers as they seem to be taking the reins at the trade show this year, both in filament and powder form. Take a look and see what you think of our choices which we have listed below in no particular order!

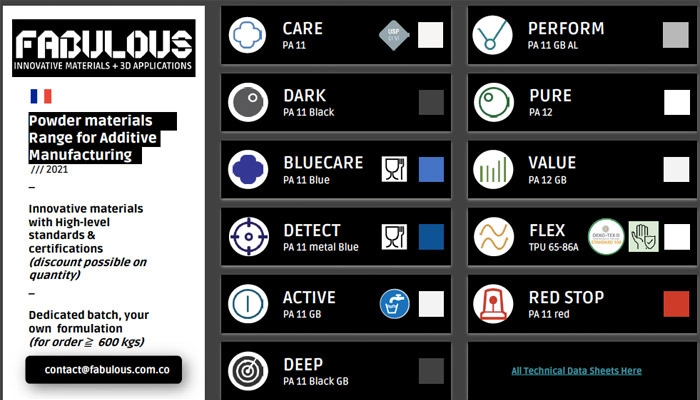

Fabulous Unveils Two New Industrial Powders

After presenting its “Safety and Security” range a few months ago, which includes the Bluecare material for the food industry, 3D printing powder manufacturer Fabulous is unveiling two new PA11 materials compatible with powder bed technologies at Formnext 2021.

Building on its recent patents, Fabulous is moving into the production of solution-tinted powders, starting with “Red Stop,” a red-colored thermoplastic for the production of easily detectable safety parts. The second material, called DETECT, is a navy blue magnetic powder that can be detected by X-rays and is intended for a number of sectors, including the medical, nuclear and food industries. On its booth 12.1-F38, Fabulous also invites visitors to rediscover BLUECARE, its powder certified for food contact in the European Union and in the process of being validated by the FDA in the United States, specially designed for the food industry. Learn more at Fabulous’ booth, F38 in Hall 12.1.

Silicones for Additive Manufacturing

Elkem Silicones specializes in the production of silicone and is particularly targeting the additive manufacturing market with its AMSil™ & AMSil SILBIONE™ ranges, which are compatible with Liquid Deposition Modeling technology, an extrusion process. Present at Formnext 2021 on booth 12.1 G14, it is showcasing its innovative materials to meet the growing demand from manufacturers. The first range, the AMSil™ has been thought for the design of industrial applications whether in the automotive, aeronautics or even electronics industries. The second was designed for the medical sector and offers a durable and biocompatible silicone.

Note that Elkem’s silicones for additive manufacturing have excellent thermal stability, good oxidation and UV resistance, and compression set. They also have dielectric properties. Feel free to visit the Elkem booth, G14 in hall 12.1, or go to their website HERE to learn more.

UpNano introduces two innovative materials for optical applications

The Viennese startup UpNano is launching two material innovations on the additive manufacturing market at once: UpBlack and UpOpto. These are photopolymers that are compatible with the company’s proprietary 2PP 3D printing process. UpOpto, for example, is said to enable printing of translucent parts, and UpBlack is said to enable printing of non-translucent black parts. The latter has posed a challenge in 3D printing in the past due to the absorbent nature of black, with black resin causing difficulties with polymerization efficiencies in the printing process. Using UpBlack with UpNano’s NanoOne eliminates this barrier. When combined with UpOpto, both materials are said to be usable for optical, biological and medical applications. UpBlack can be used for the housing of optical devices, while UpOpto can be used for optical lenses. UpOpto also has EN ISO 10993-5:2009 certification, which states that the material is non-cytotoxic and biocompatible. Discover more about the materials at booth G41 in Hall 12.1

3D printing of injection molds with Somos® WaterShed AF.

Covestro, a German materials manufacturer, will also be presenting a new resin for stereolithography at Formnext 2021. According to the manufacturer, Somos® WaterShed AF’s low viscosity makes it particularly suitable for producing investment casting molds and other complex parts with a high level of detail. Users also benefit from the material’s high dimensional stability and low moisture absorption. According to Covestro, all materials in the Somos® WaterShed range have these properties, making them suitable for applications such as aerospace, transportation, energy and utilities. With the material series, the Leverkusen-based company is expanding its product range for 3D printing of injection molds. You can visit Covestro’s booth at Formnext, they are at booth C11 in Hall 12.1.

Sinterit PA11 Carbon Fiber for SLS

PA 11 Carbon Fiber positions itself as a bio-derived powder composite material. This castor oil-based material from Sinterit is based on Polyamide 11 enhanced with carbon fiber, thereby offering improved performance and rigidity. This material boasts a high strength-to-weight ratio in addition to high thermal properties which is an ideal for usage in sectors such as automotive for motorsport parts or metal replacement parts, as well as in aerospace models. Furthermore, this material’s mechanical and thermal properties perform well for various medical applications such as prostheses. Due to PA 11 Carbon Fiber’s impact strength, it is one of the strongest and most versatile materials available on the SLS powder market. Learn more about the Polish manufacturer’s material at booth F09 in Hall 12.1.

Lehvoss Group High-Performance Sustainable Thermoplastics

Lehvoss Group has developed a suite of sustainable thermoplastic 3D printing materials. With their carbon footprint substantially reduced, the company’s flagship materials that feature the suffix ‘eco’ in the product name, e.g. LUVOTECH® eco, are marketed as sustainable because they are made with recycled polymers which are sourced from post-production processes. These customized polymer materials offer superior technical performance which are based on PA6, PA66, PC / ABS and PEEK. You can find the Lehvoss Group at Booth G109 in Hall 12.1.

Evonik’s Latest Photopolymers

Evonik’s newest photopolymers for industrial 3D printing, INFINAM® RG 3101 L and INFINAM® FL 6300 L, will also be presented for the first time at Formnext this year. These ready-to-use materials have been designed to be suitable for hard or flexible 3D applications and can be used with common photopolymer 3D printing processes, including SLA and DLP. INFINAM® RG 3101 L has excellent impact and high-temperature resistance, meaning that parts made using it can be processed by machines as they will remain fracture-resistant even when subject to strong forces. Meanwhile INFINAM® FL 6300 L is the first industrially suitable elastomer from the photopolymer class, allowing users to making high flexible 3D objects with excellent material properties that are essential for elastomers. You can see them for yourself at booth C69 in Hall 12.1 at Formnext.

Massivit3D’s Industrial Materials

Israeli company, Massivit 3D, which is known for its large-scale 3D printing systems has also released two exciting new materials in preparation for Formnext 2021. The Dimengel 20-FR (DIM 20-FR) is the first flame-retardant, photo polymeric gel developed for 3D printing while the Dimengel 300 (DIM 300) offers high translucency. Both materials were created as a way to expand applications for customers using Massivit machines, especially their most recently launched printer the Massivit 5000. They are suitable for applications in many fields including architecture, aerospace, marine, automotive and more. Make sure to check out the materials for yourself in Hall 12.1, booth C119.

Arkema Will Showcase Multiple New Materials

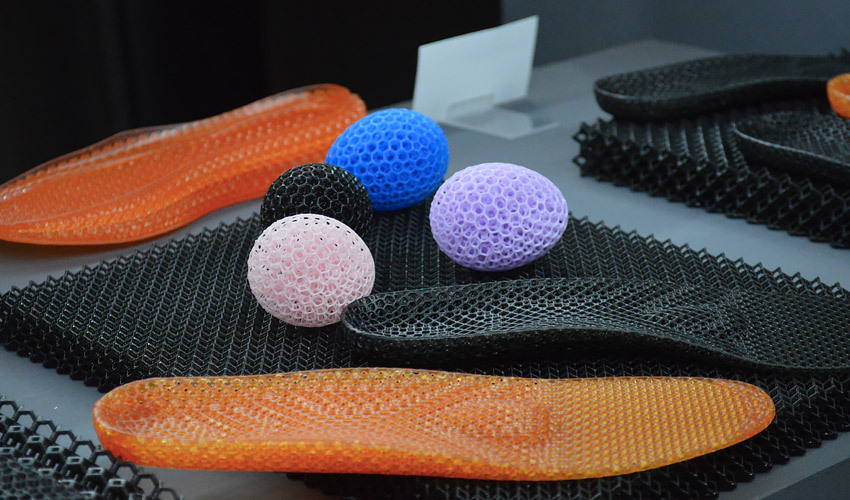

French chemical and advance materials company, Arkema, also unveiled its latest materials at the trade show for a number of different 3D printing technologies. For UV-curing, they have five new high performance custom formulations N3D-TOUGH784, HT511, N3D – MODEL115, IC163, and PRO22802 which will help customers in a variety of different industries. They also have a new range of ultra-low loss materials for advanced electronic applications, including radio frequency applications, PRO14729, PRO14730 and PRO14731. Beyond UV-curing, they will also showcase the new SLS PEBAX powder, designed as you might have guessed for SLS 3D printing. The partially bio-based thermoplastic elastomer will have both strength, flexibility and elasticity, making it suitable for sports, medical, and industrial applications. You can visit Arkema at booth F119 in Hall 12.1.

Leave A Comment