SLA/DLP Materials

Stereolithography can build large parts with very good accuracy and surface finish. A wide range of material allow to build parts with specific characteristics. However, stereolithography only works with photopolymers which are not stable over time and have not well defined mechanical properties. Read more about SLA/DLP process.

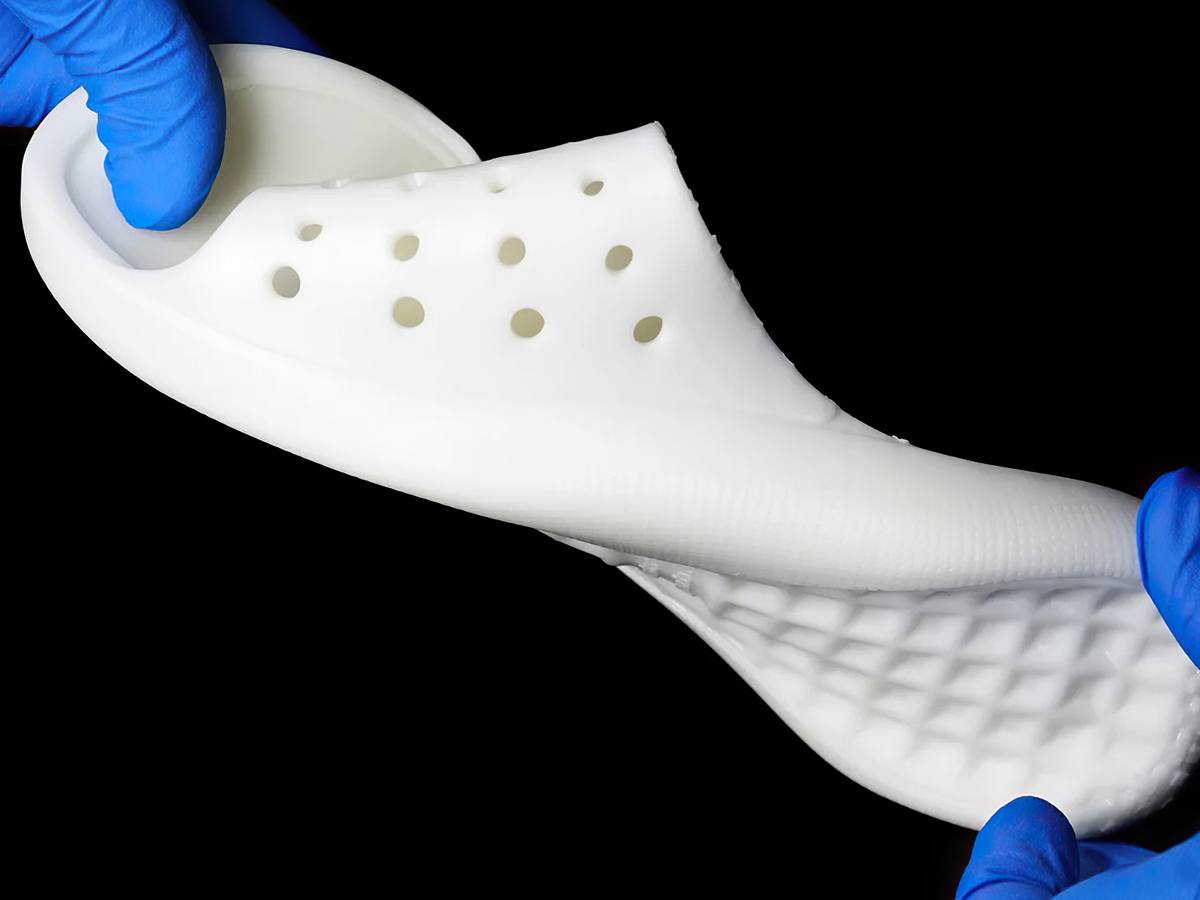

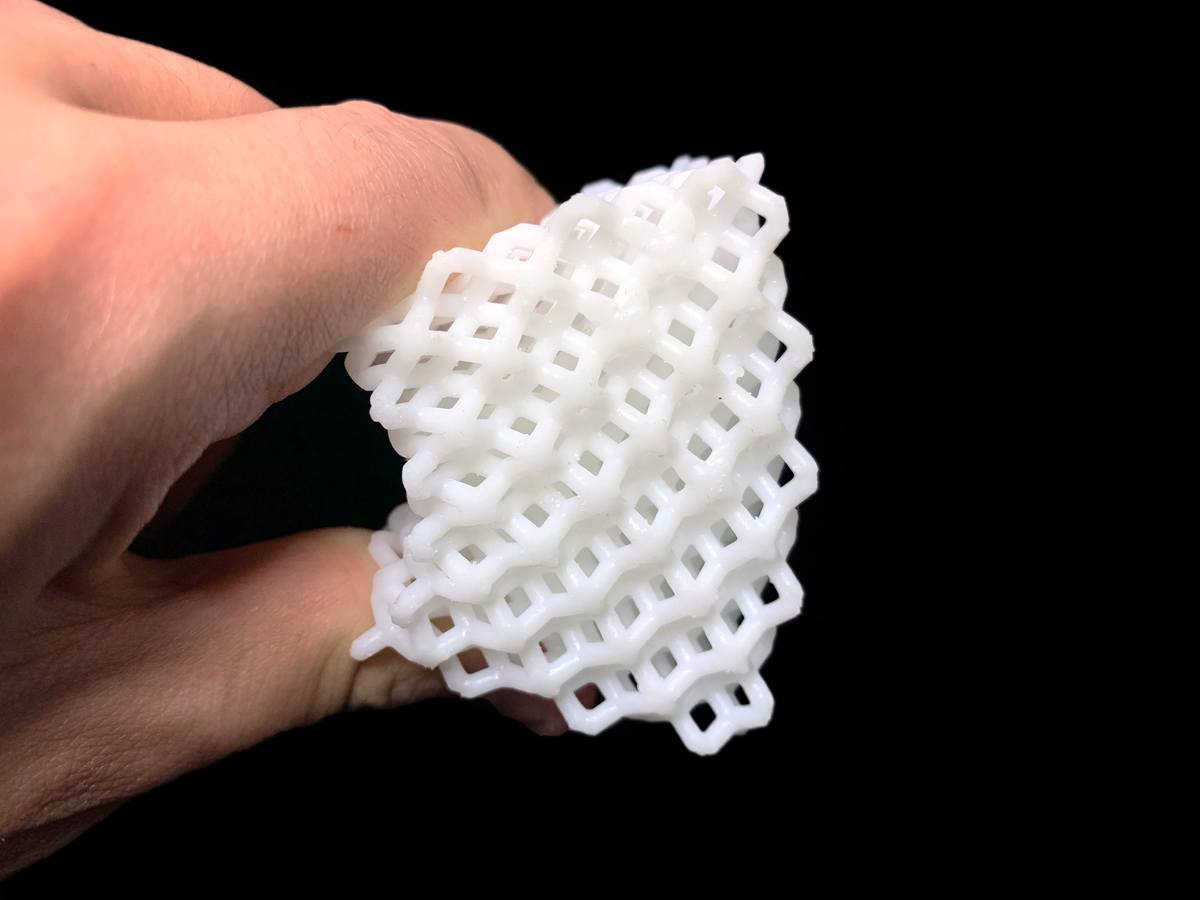

LCD Rubber-like Resin

This 75A ShoreA durometer material is suitable for prototyping parts normally produced with silicone like shoe sole and connectors. DLP resin is ideal for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing.

Max Size:

Min Size:

5 x 5 x 5 mm

Default Layer Height:

0.1 mm

Optional Layer Heights(mm):

0.05, 0.1

Tolerance:┬▒0.2% (with a lower limit of ┬▒0.2 mm)

Heat endurance:Under 50 Ōäā

Smooth: ŌśģŌśģŌśģŌśģ

Detail: ŌśģŌśģŌśģ

Accuracy: ŌśģŌśģŌśģ

Rigidity: Ōśģ

Flexibility: ŌśģŌśģŌśģŌśģŌśģ

Available Colors

Available Post Process

Suitable For

Cases, holders, adapters,

Low-cost prototype

Not Suitable For

Complex designs with intricate details,

Fine-detail models with smooth surfaces,

Moving and assembled parts,

Large models

Additional Info

A supported wall is one connected to other walls on two or more sides. | 1 mm |

An unsupported wall is one connected to other walls on less than two sides. | 1 mm |

A wire is a feature whose length is greater than five times its width. A supported wire is connected to walls on both sides. | 1 mm |

A wire is a feature whose length is greater than five times its width. An unsupported wire is connected to walls on less than two sides. | 1 mm |

A detail is a feature whose length is less than twice its width. The minimum detail is determined by the printer's resolution.When detail dimensions are below the minimum, the printer may not be able to accurately replicate them. Details that are too small can also be smoothed over in the polishing process. To ensure details come out clearly, make them larger than the indicated minimum. We may refrain from printing products with details smaller than the minimum, since the final product will not be true to your design. If your product has details smaller than the minimum, try making them larger, removing them, or considering a material with finer detail. | 0.5 mm |

A detail is a feature whose length is less than twice its width. Engraved or debossed details go into a surface. | 0.5 mm |

Clearance is the space between any two parts, walls or wires. To ensure a successful product, make the clearance between parts, walls, and wires greater than the indicated minimum. If your clearance is too small, try making the gap bigger, or consider fusing the parts or features if their independence is unnecessary. You can also try a material with a smaller minimum clearance. | 1 mm |

Escape holes allow unbuilt material inside hollow products to be removed. Normally you don't need to consider this, our technician will add escape holes before printing. When products contain hollow cavities, they are often filled with powder/liquid even after they are removed from the build tray. If escape holes are not large enough, or the geometry of the product makes it difficult to shake or blast the powder out, we cannot successfully clean it. | 8 mm |

Sometimes the interlocking/moving parts can't be printed, since the supports inside the cross section can't be removed. | |

Because each layer needs to build off the last, for some material, angles of more than 45 degrees generally require supports to be printed along with the design. Supports are not inherently detrimental for your design, but they do add complexity to the printing process and lead to less smooth finish on overhanging parts. | Yes |

Feature

Watertight | Foodsafe | Glueable | Recycleable |

Biocompatible | Biodegradable | ||

3D Printer

Customized LCD PrinterMaterial Spec Sheet

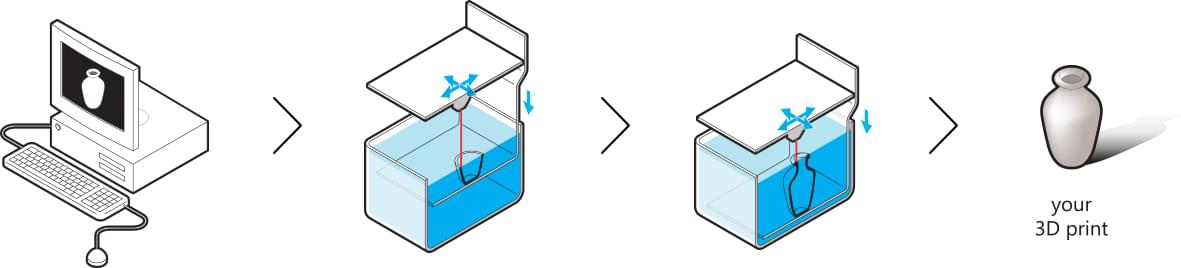

LCD Rubber-like Resin is 3D printed using DLP/SLA (Digital Light Processing/Stereolithography) technology.

Stereolithography is used to build your design with this material.Starting from a 3D model, a model is built by cutting it into thin layers via specialized software.

A support structure is created, where needed, in order to deal with overhangs and cavities.

The process takes place in a large tank and begins when a layer of liquid polymer is spread over a platform. This machine then uses a computer controlled laser to draw the first layer onto the surface of a liquid polymer, which hardens where struck by the laser. The model is then lowered and the next layer is then drawn directly on top of the previous one. This is repeated until the model is finished. In this way, layer by layer, an object is ŌĆ£drawnŌĆØ in the liquid by the beam, with the layers being consolidated throughout the process.

When the object is complete, it is raised out of the tank via the supporting platform ŌĆō much like a submarine rising to the surface of the water ŌĆō with the excess liquid flowing away. The supports are removed manually after the model is taken from the machine.

How is DLP/SLA 3D Printing Working?

SLS Materials

Laser sintering can manufacture parts in standard plastics with good mechanical properties. There is a constantly growing set of materials available. However, parts do not have exactly the same properties as their injection molded counterparts. Read more about SLS process.

You are not allowed to view this content.

DMLS/SLM Materials

Laser melting can manufacture parts in standard metals with high density, which can be further processed as any welding part. However, the technology is rather slow and expensive as well as surface finishes are limited. Read more about SLM/DMLS process.

You are not allowed to view this content.

MJF Materials

Multi Jet Fusion can manufacture parts in standard plastics(even with full color) with good mechanical properties. There is a constantly growing set of materials available. However, parts do not have exactly the same properties as their injection molded counterparts. Read more about MJF process.

You are not allowed to view this content.

PolyJet/MJP Materials

Multiple materials can be jetted together allowing multi-material and multi-color parts. Functionally graded materials are possible. However, the technology does not work with standard materials but with UV-active photopolymers which are not durable over time. Read more about PolyJet process.

You are not allowed to view this content.

Binder Jetting Materials

Binder jetting is a rather fast and cheap technology, working with a wide arrange of material types. Parts in full color are possible. However, parts coming directly from the machine have limited mechanical characteristics. Read more about PolyJet process.

You are not allowed to view this content.

Wax Jetting Materials

Material jetting can achieve very good accuracy and surface finishes. However the technology only works with wax-like materials. The technology can achieve very good accuracy and surface finishes. Due to the type of material, parts are rather fragile. The build process is rather slow.

You are not allowed to view this content.

FDM Materials

Fused deposition modeling can build fully functional parts in standard plastics. However, they have an anisotropy in the z-direction (vertical direction) and a step-structure on the surface. Read more about FDM process.

You are not allowed to view this content.