Gallery

About Project

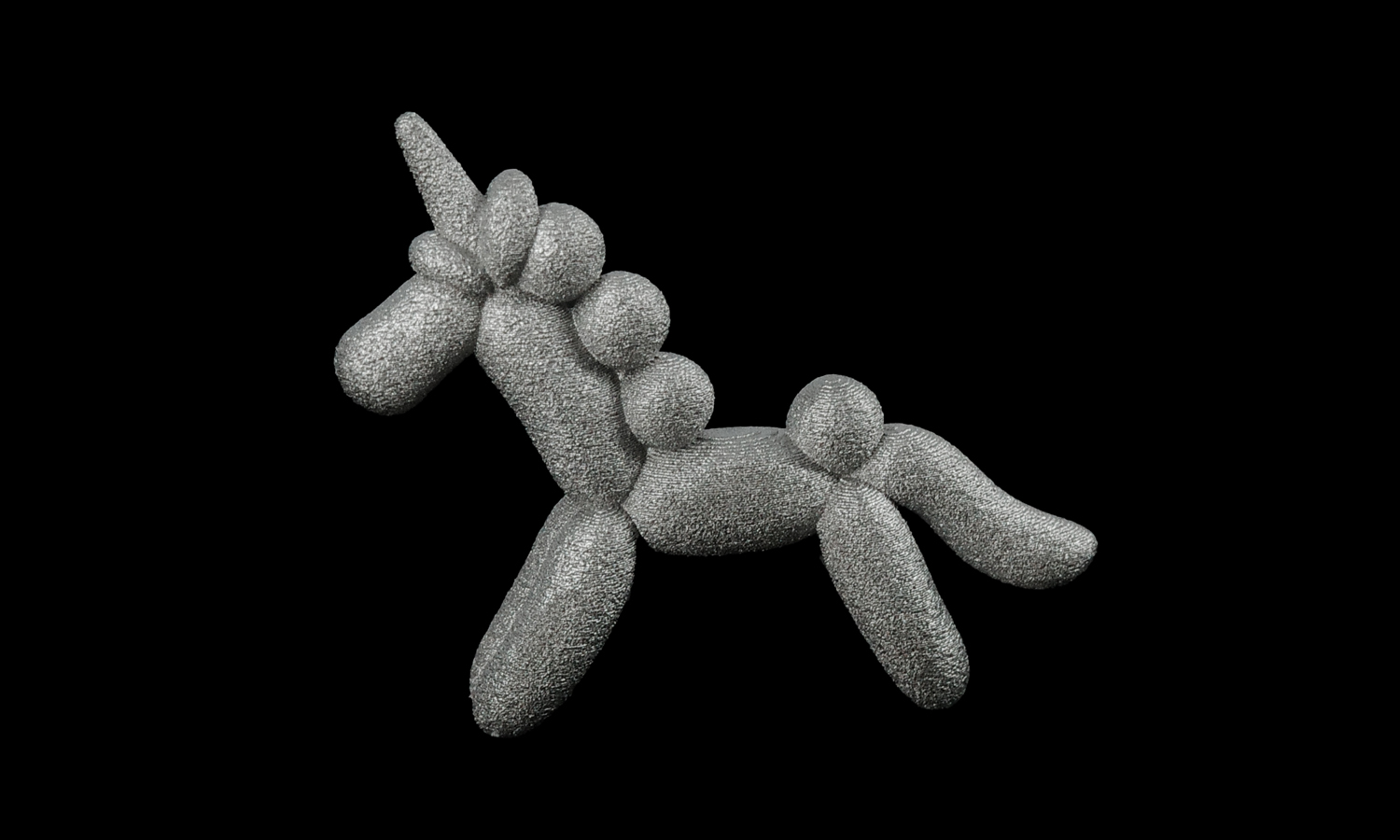

Behold the magic of 3D printing! This enchanting unicorn balloon miniature, crafted in durable SS316L stainless steel, is a testament to the incredible capabilities of modern manufacturing.

Each intricate detail, from the flowing mane to the delicate horn, is meticulously captured in this miniature masterpiece. The raw, layered finish adds a unique industrial charm, highlighting the 3D printing process itself.

This isn’t just a toy; it’s a functional piece of art that can be admired on a desk or shelf. Its sturdy construction and timeless design make it a perfect gift for any occasion.

Looking to bring your own 3D designs to life? FacFox offers a wide range of 3D printing services, including BinderJet 3D printing in stainless steel. Our team of experts can help you transform your ideas into reality.

Contact us today to learn more about our services and get a quote for your next project.

Solution

- Step 1: 3D Model Creation. A digital 3D model of the unicorn balloon miniature was first created using computer-aided design (CAD) software.

- Step 2: Data Slicing. The 3D model was then sliced into thin, horizontal layers.

- Step 3: Powder Bed Preparation. A thin layer of stainless steel powder was spread evenly across a build plate.

- Step 4: Binder Jetting. A printhead jetted a liquid binder onto the powder, selectively binding particles together to form the shape of the first layer of the object.

- Step 5: Powder Recoating. A new layer of powder was spread over the partially built object, covering the previous layer.

- Step 6: Layer-by-Layer Build. Steps 4 and 5 were repeated, layer by layer, until the entire object was built.

- Step 7: Debinding. The built object, still embedded in the powder, was removed from the build chamber and subjected to a debinding process to remove the binder.

- Step 8: Sintering. The debinded object was sintered in a high-temperature furnace. During sintering, the metal powder particles fused together, creating a solid, dense object.