- SS304 Bionic Mechanical Part Cast from SLA 3D Printed Resin Pattern

- Urethane Cast Black TPU Vivo Phone Case Low-volume Customization

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

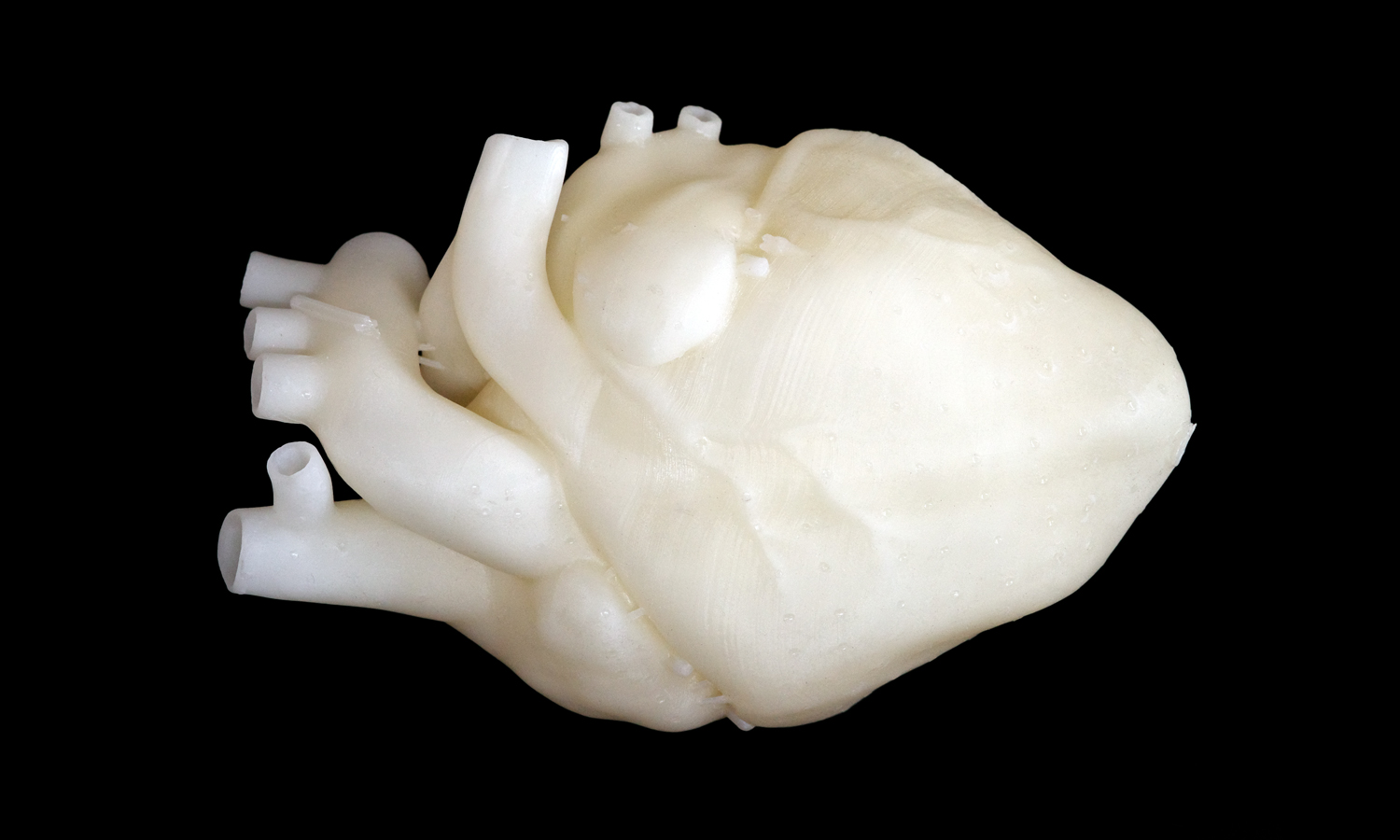

This incredible model offers an accurate representation of a real human heart, boasting the same size and intricate details. Crafted using DLP Flexible Resin, it provides a unique experience by allowing you to interact with it in a whole new way.

Designed to replicate the complexities of the human heart, this model showcases the fascinating network of blood vessels, chambers, and valves found in the actual organ. While the layer lines may be visible due to the absence of a polishing post-process, they serve as a testament to the authenticity and precision of the 3D printing technology used.

What sets this heart model apart is its hollowed and flexible construction, enabling you to pinch and squeeze it for a tactile understanding of its structure. By offering a hands-on experience, it facilitates enhanced learning, making it an invaluable tool for medical professionals, educators, and enthusiasts alike.

To bring your innovative ideas to life and create unique 3D printed models like this flexible anatomical heart, FacFox’s manufacturing services are the perfect match. With their expertise in additive manufacturing techniques and commitment to quality, FacFox can meet your specific requirements with precision and professionalism.

Experience the future of medical education and research with the DLP 3D Printed Flexible Resin Anatomical Heart Model. Contact FacFox today via info@facfox.com to explore their exceptional manufacturing services and unlock endless possibilities in anatomical modelling. Discover the true potential of 3D printing technology in the field of healthcare and beyond!

Solution

- Step 1: The digital design of the anatomical heart model was created by a skilled designer, ensuring accurate and detailed representation.

- Step 2: The design was prepared for 3D printing by adding necessary supporting structures and converting it into digital slices or layers.

- Step 3: The DLP 3D printer was prepared, and the build platform was coated with a thin layer of DLP Flexible Resin.

- Step 4: The sliced design files were loaded into the 3D printer’s software, setting the necessary parameters for the printing process.

- Step 5: Layer by layer, the flexible resin was selectively cured by the DLP projector, solidifying each cross-section of the heart model.

- Step 6: As the printing progressed, the hollowed structure of the heart model began to take shape, replicating the intricacies of the human heart.

- Step 7: Once the printing was complete, the heart model was carefully removed from the build platform and post-processed.

- Step 8: The model underwent necessary cleaning and curing processes to ensure its structural integrity and optimal flexibility.

- Step 9: Although some layer lines remained visible on the surface, the model was left unpainted, preserving its authenticity and showcasing the material in its raw form.