- DLP 3D Printed Flexible Resin Anatomical Heart Model

- Typhoon (Doksuri and Khanun) alert: Shipping schedule might be affected!

Material Plastic

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Gallery

About Project

Are you looking for a durable, flexible, and stylish phone case for your Vivo smartphone? Do you want to customize your own design without spending a fortune? If yes, then you might be interested in our Urethane Cast Black TPU Vivo Phone Case Low-volume Customization service.

Urethane casting is a process that uses silicone molds and liquid urethane resin to produce high-quality plastic parts in small quantities. It is ideal for prototyping, testing, and low-volume production of complex and intricate designs. Urethane casting can also create parts with different colors, textures, and finishes.

One of the materials we use for urethane casting is thermoplastic polyurethane (TPU), which is a type of elastomer that combines the properties of rubber and plastic. TPU is resistant to abrasion, oil, grease, and chemicals. It also has excellent elasticity, flexibility, and durability. TPU can be dyed into various colors, such as black, to match your preference.

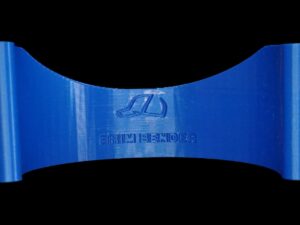

Our Urethane Cast Black TPU Vivo Phone Case Low-volume Customization service allows you to create your own phone case with your desired design and logo. You can send us your 3D model or sketch, and we will make a silicone mold based on it. Then, we will inject the black TPU resin into the mold and cure it under heat and pressure. The result is a smooth, sleek, and sturdy phone case that fits your Vivo phone perfectly.

The Urethane Cast Black TPU Vivo Phone Case has many advantages over other phone cases. It protects your phone from scratches, drops, and impacts. It feels comfortable and soft in your hand. It has a clear and sharp Vivo logo on the back. It has precise holes for the camera, speaker, charger, and buttons. It also has a matte finish that prevents fingerprints and smudges.

If you are interested in our Urethane Cast Black TPU Vivo Phone Case Low-volume Customization service, please contact us via info@facfox.com today. We offer fast turnaround time, competitive pricing, and high-quality products. We can also provide other colors and materials for urethane casting, such as clear, white, red, blue, green, yellow, etc. We are looking forward to hearing from you soon.

Solution

- Step 1: Design Submission. The customer submitted a 3D model or sketch of the phone case design to FacFox.

- Step 2: Mold Making. FacFox made a silicone mold based on the 3D model or sketch using advanced CNC machining and 3D printing technologies.

- Step 3: Material Preparation. FacFox prepared black TPU resin with high-quality raw materials and additives to ensure optimal mechanical properties, color consistency, and surface finish.

- Step 4: Injection Molding. FacFox injected the black TPU resin into the silicone mold using a state-of-the-art injection molding machine with precise temperature, pressure, and timing controls.

- Step 5: Curing. FacFox cured the resin under heat and pressure to ensure complete polymerization, dimensional stability, and surface quality.

- Step 6: Demolding. FacFox removed the phone case from the mold using special release agents and techniques to avoid any damage or deformation.

- Step 7: Finishing. FacFox inspected and polished the phone case to remove any flash, gate marks, or surface defects. FacFox also added a matte finish to prevent fingerprints and smudges.

- Step 8: Quality Control. FacFox conducted rigorous quality control tests on the phone case to ensure it meets the customerās specifications and industry standards.

- Step 9: Packaging & Shipping. FacFox packaged the phone case in a protective box with custom labels and shipped it to the customer using reliable logistics partners.