- SLS 3D Printed Nylon Threaded Two Hole Pins Set for Pipe Fitting

- SLS 3D Printed Nylon PA 12 Evaporator Blower Wheel

Gallery

About Project

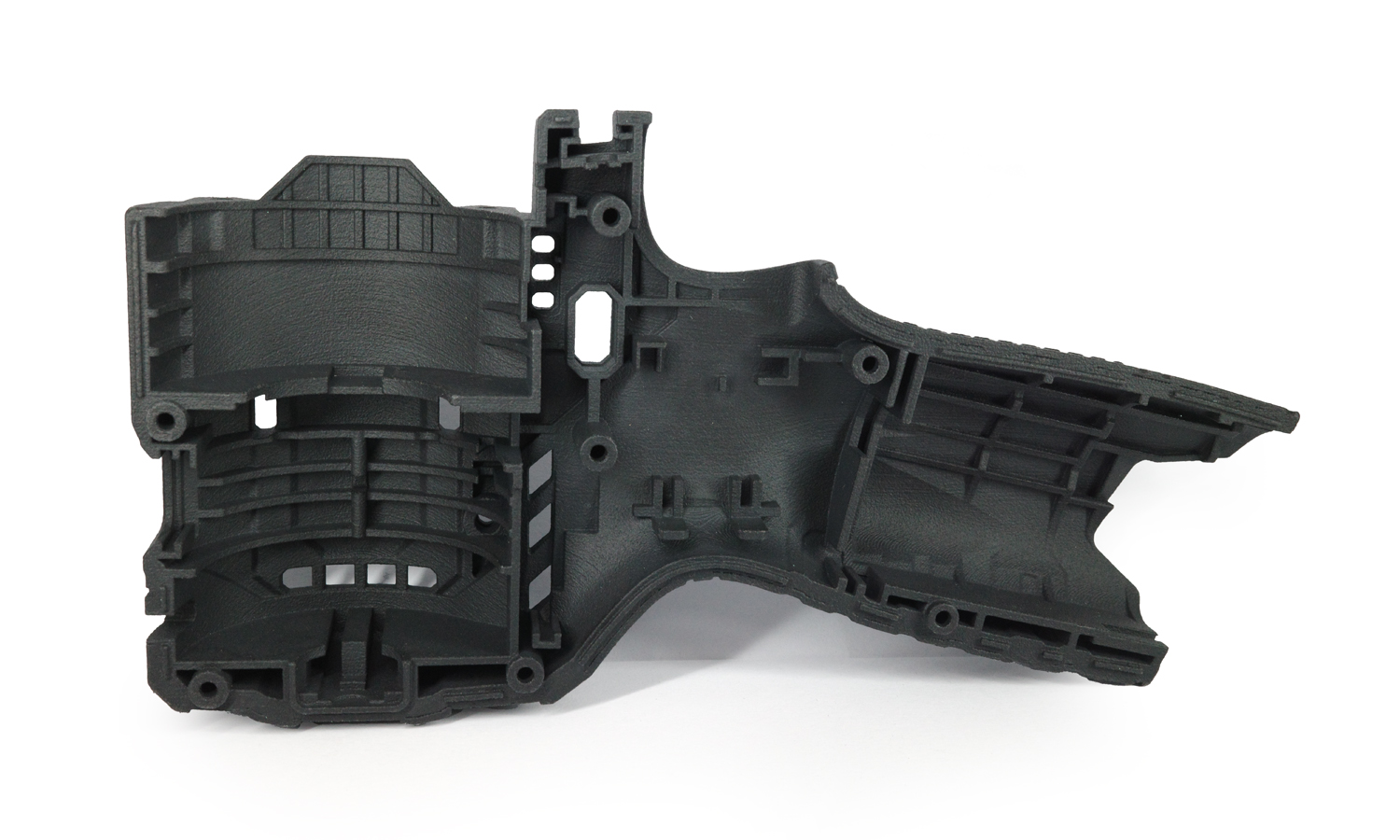

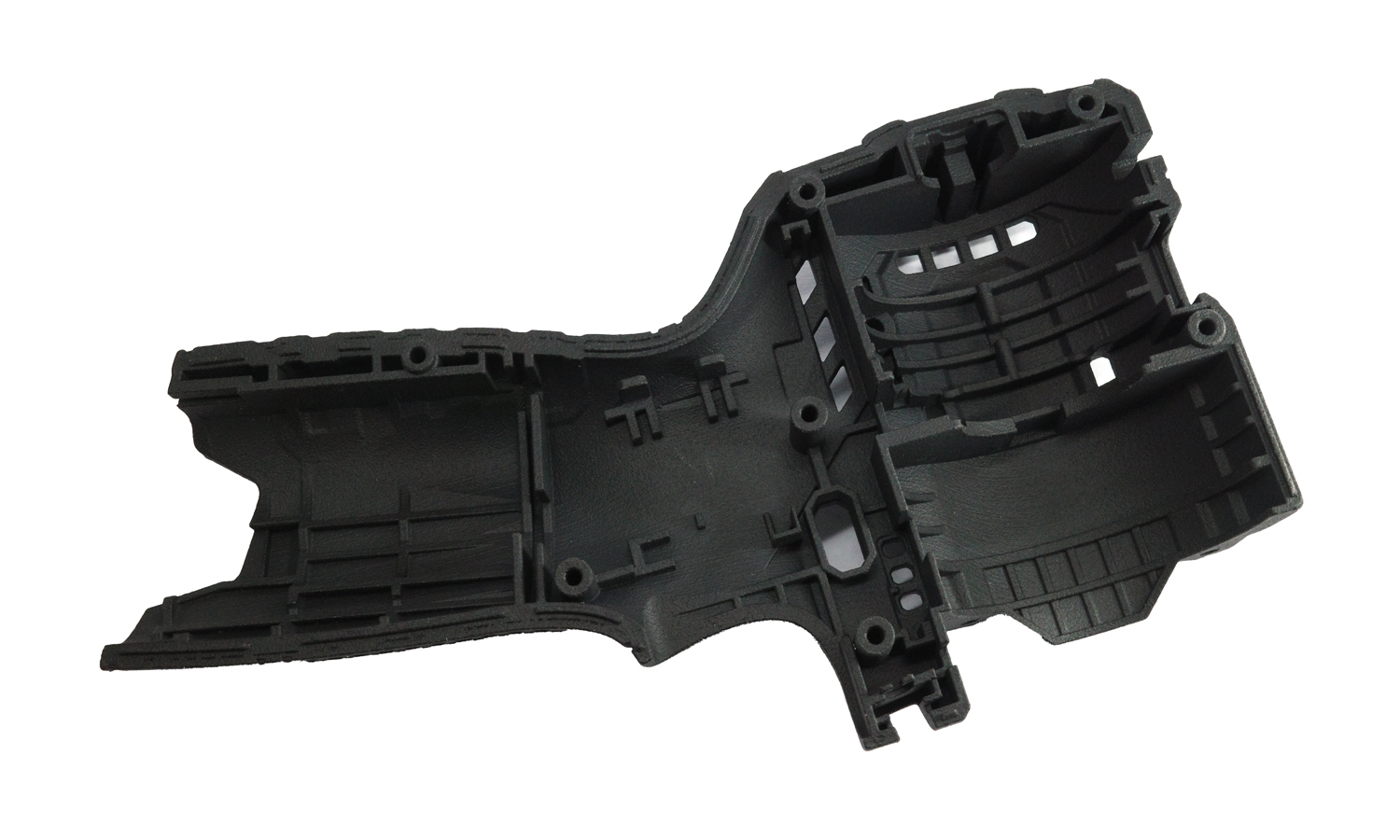

This rugged, intricately designed enclosure is a shell for a brushless electric drill, 3D printed using Selective Laser Sintering (SLS) with PA 12 GF (Glass-Filled Nylon 12). Shown here in two halves, the enclosure features an ergonomic grip texture, internal ribs for reinforcement, and precision slots for electronics, switches, and screws.

Design and Function

The part is engineered to house internal components like motors, gears, and batteries, with thoughtful partitioning and ventilation slits. The interior ribbing improves structural integrity without adding unnecessary bulk. Textured grip surfaces and mounting points enhance usability and reliability in handheld operation.

Material Spotlight: PA 12 GF

PA 12 GF (Glass-Filled Nylon 12) is a composite material blending nylon with short glass fibers. This boosts stiffness, thermal stability, and dimensional accuracy, making it ideal for functional prototypes and production parts subject to mechanical stress. It’s particularly suitable for power tool housings, automotive parts, and jigs and fixtures.

Key properties:

- High strength and stiffness

- Excellent heat resistance

- Superior dimensional stability

- Good chemical resistance

Print Quality Evaluation

The enclosure exhibits solid layer fusion, crisp detailing, and clean internal geometries-all hallmarks of a high-quality SLS print. Minor powder roughness is visible on the surface, which is typical of SLS parts and may be lightly post-processed if a smoother finish is needed. All holes, slots, and alignment features are well-resolved, showing tight tolerances achievable with SLS.

The grainy matte texture gives the part a professional, ready-to-use look. No warping or distortion is present, confirming the success of both material selection and print parameters.

Why Choose FacFox?

Whether you’re building functional prototypes or end-use components, FacFox’s SLS 3D printing services provide industrial-grade quality at competitive rates. Our expertise in printing with PA 12 GF and other advanced materials ensures you get durable, high-performance parts with rapid turnaround times.

Need reliable parts fast? Choose FacFox for your next engineering project and experience production-grade strength without the mold.

Solution

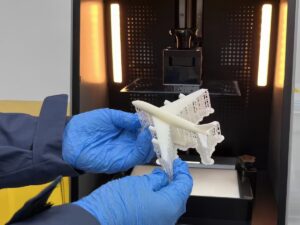

- Step 1: The 3D model of the drill enclosure was prepared and optimized for SLS printing.

- Step 2: PA 12 GF powder was evenly spread layer by layer inside the SLS printer.

- Step 3: Each cross-section of the part was selectively sintered by a laser based on the CAD data.

- Step 4: The process was repeated layer by layer until the full geometry was built.

- Step 5: The printed part was allowed to cool inside the build chamber to avoid warping.

- Step 6: Loose powder was removed from the enclosure using air blasting.

- Step 7: The part was inspected for dimensional accuracy and structural integrity.