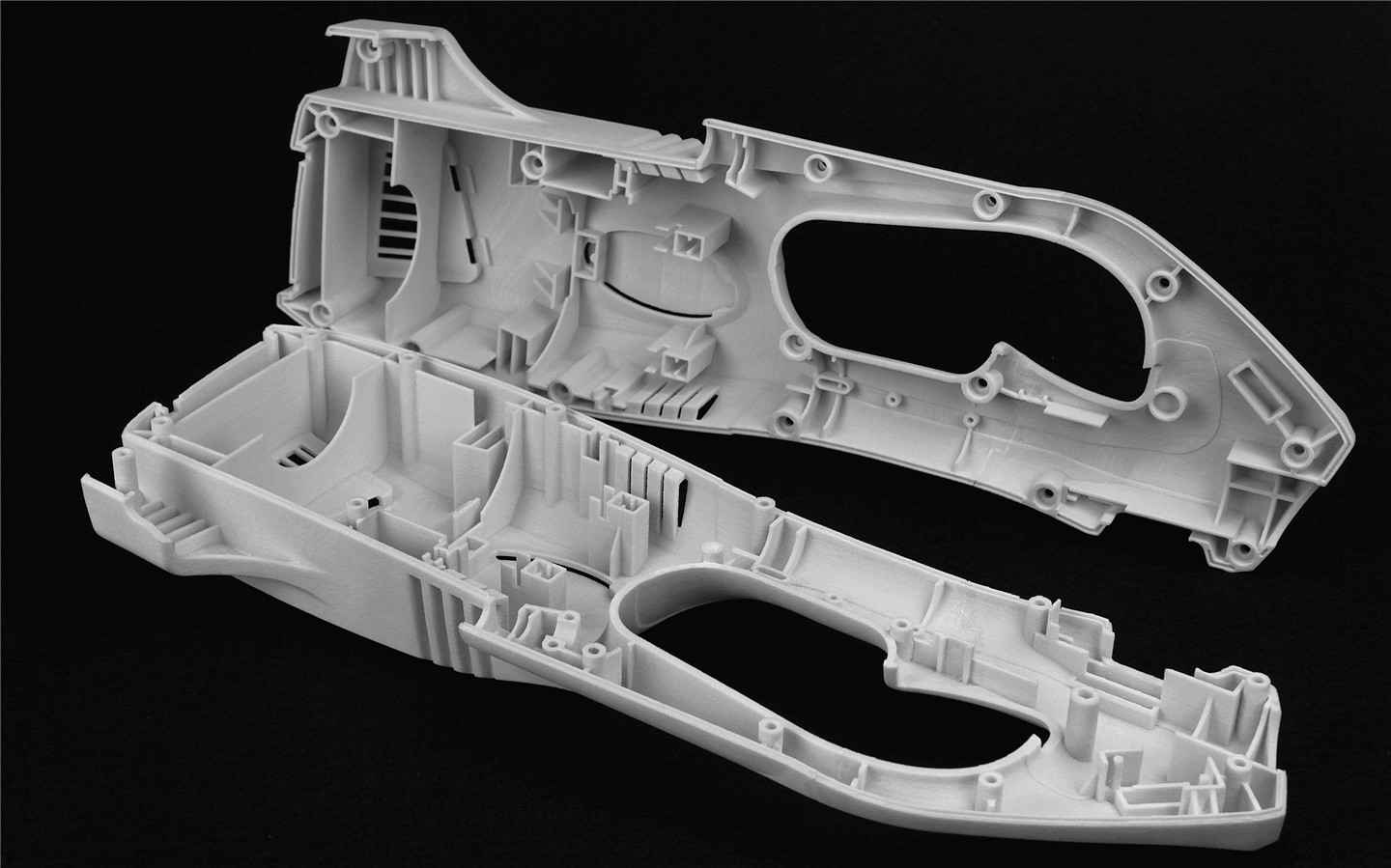

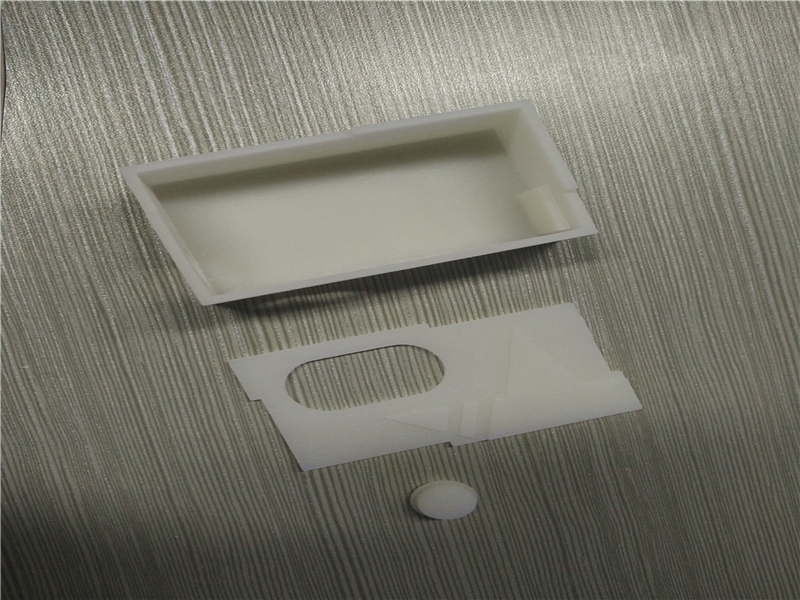

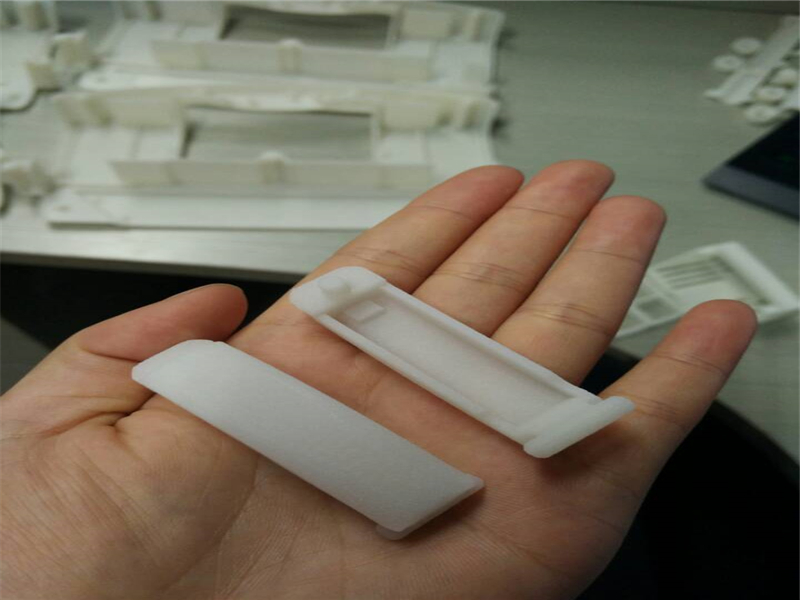

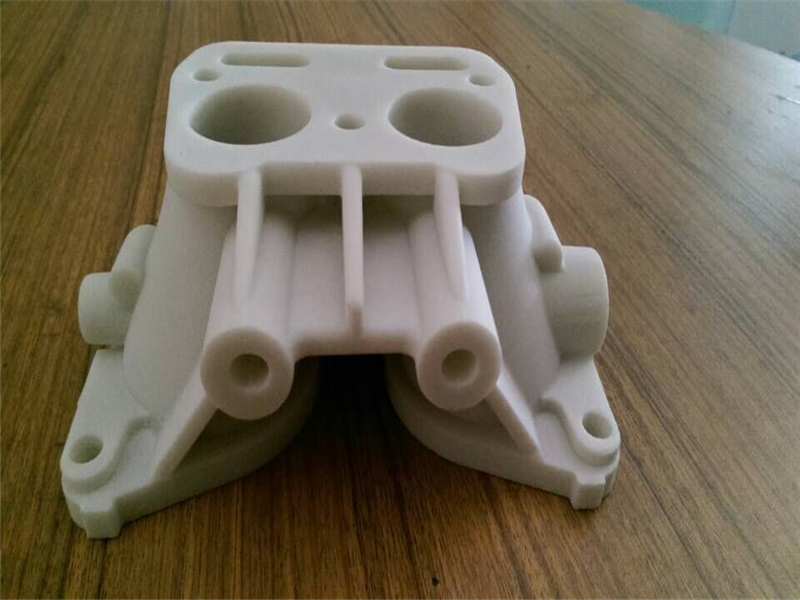

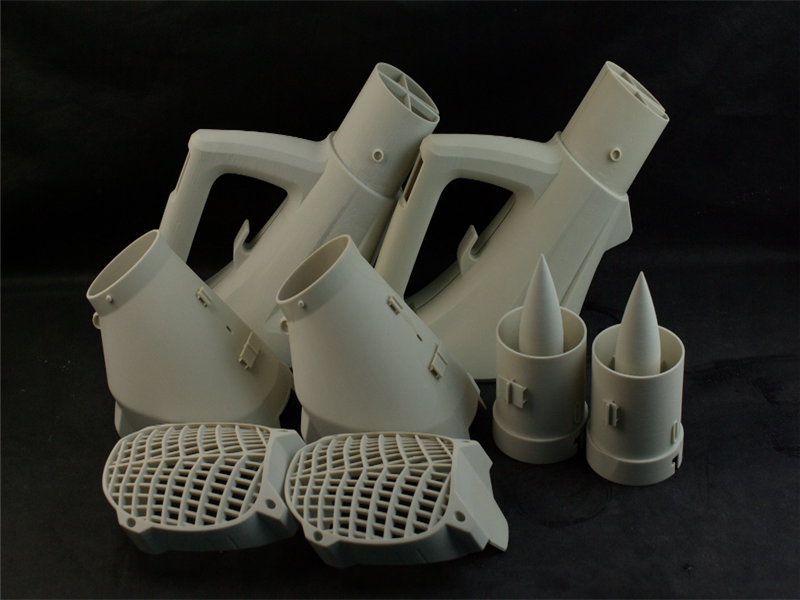

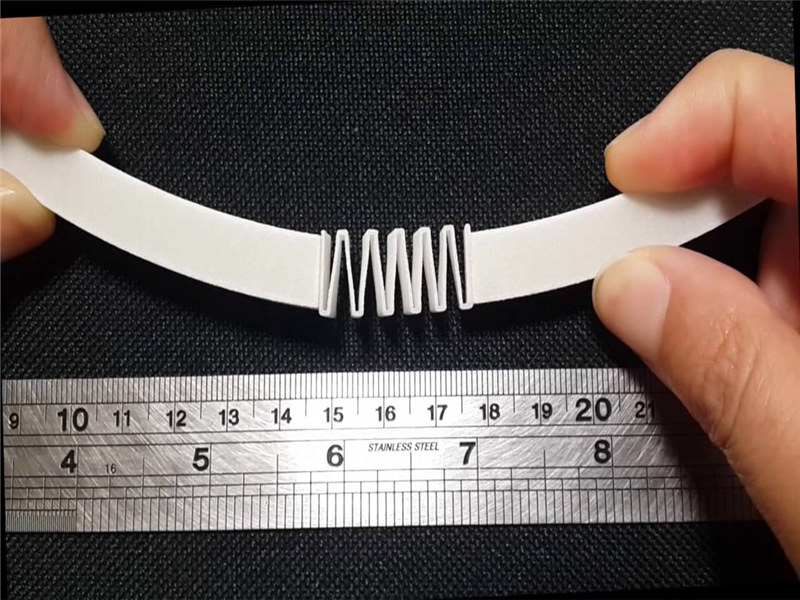

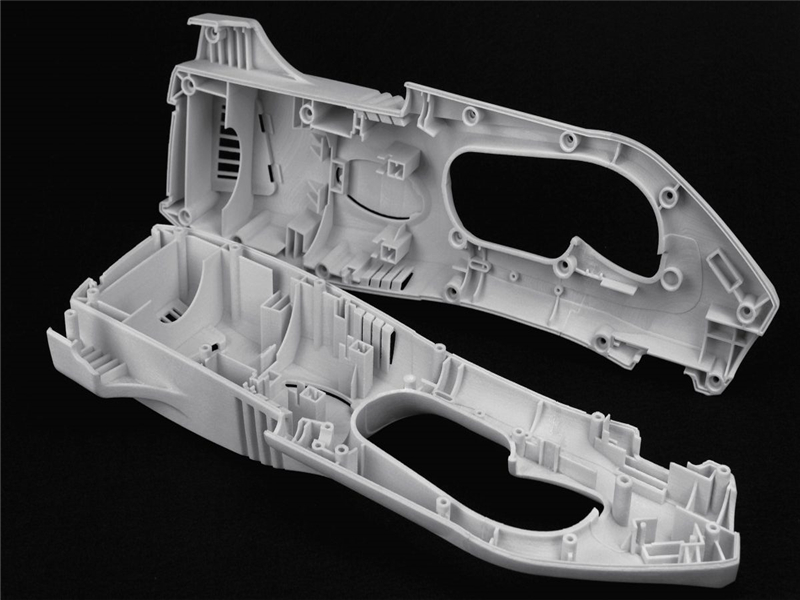

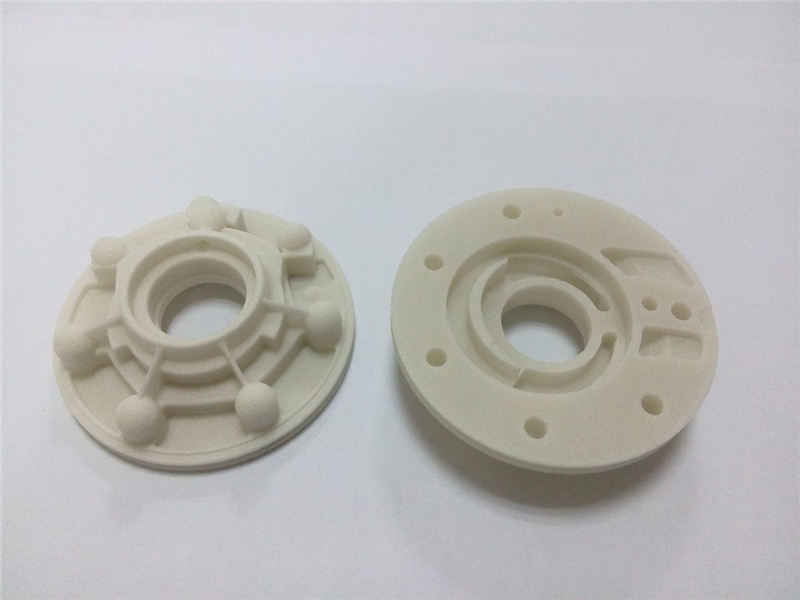

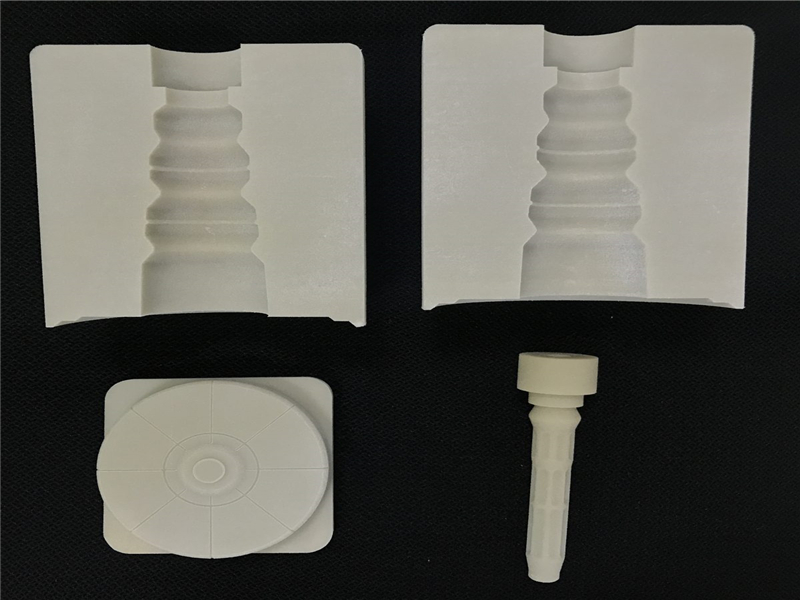

SLS Nylon PA12 GlassfilledPA12 Glassfilled The surface of the material is white and slightly granular and porous. Nylon Glassfilled(PA3200 GF) is more durable and resistant than Nylon (PA12). It gives you great freedom in your designs – allowing for both complex and inclosed volumes. The material is great for technical parts that need resistance and loads. The surface is not as accurate as polyamide 12 but it will fit the requirements of technical parts. Max Build Size Min Build Size 3 x 3 x 3 mm Default Layer Height 0.1 mm Optional Layer Heights 0.1 mm Tolerance ┬▒0.3% (with a lower limit of ┬▒0.3 mm) N/A Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģ Available ColorsGrey

, Painted

Available Post ProcessPaint

, Dyeing

Suitable For Functional prototypes and end products, Not Suitable For Fine-detail models with smooth surfaces, Additional InfoUses and maintenance Nylon 3200 Glass-filled (glass-filled nylon) is a great 3D printing material that allows complex and resistant models. It is durable and strong that’s why it perfectly fits technical uses. Nylon 3200 Glass-filled (glass-filled nylon) is used in many industries such as the automotive industry. It can be placed near engines and used for parts that require a lot of stresses and loads. Complex models can be realized in glass-filled nylon, just as enclosed volumes. However, t he surface of the glass-filled polyamide 3D printed objects is limited to 100 ┬Ąm that means fine details will not be optimally printed. Nylon 3200 Glass-filled (glass-filled nylon) is indeed an engineering material that is used for technical parts that require particular stiffness, high heat distortion temperature and low abrasive wear. The surface quality of the Nylon 3200 Glass-filled (glass-filled nylon) is excellent and designed for uses in dirty environments. It is mainly used for parts with requirements on abrasion and wear, stiff housings, parts used under elevated thermal conditions (for example for final parts within the engine area of cars), for deep-drawing dies, or for any other application which requires particular high heat distortion temperature, low abrasive wear and special stiffness.

Feature

3D PrinterMaterial Spec Sheet

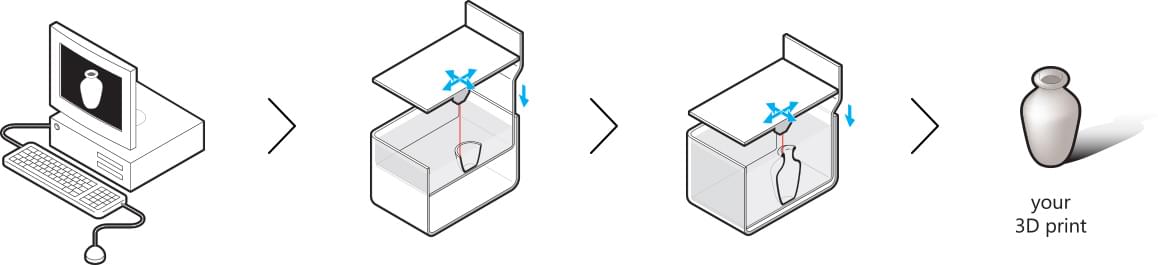

Laser sintering is used to build your design with this material. The models are printed layer by layer by a laser that draws thin lines in the powder, which melts and bonds it together in order to form a thin layer of the model. After a layer is printed, a new layer of fresh powder is spread over the surface by a roller. The printer has a print chamber that is heated to just below the melting point of the powder; the laser beam adds the extra energy to melt the powder, forming a solid model. After a print job is finished, the result is a big block of heated powder with the printed models contained inside.

|