- [Holiday OFF Notice] Mid-autumn & National Day Festival during Sep.28-Oct.6, all shipping and customer service will pause

- MJF 3D Printed PP Spring with Raw Finishing

Gallery

About Project

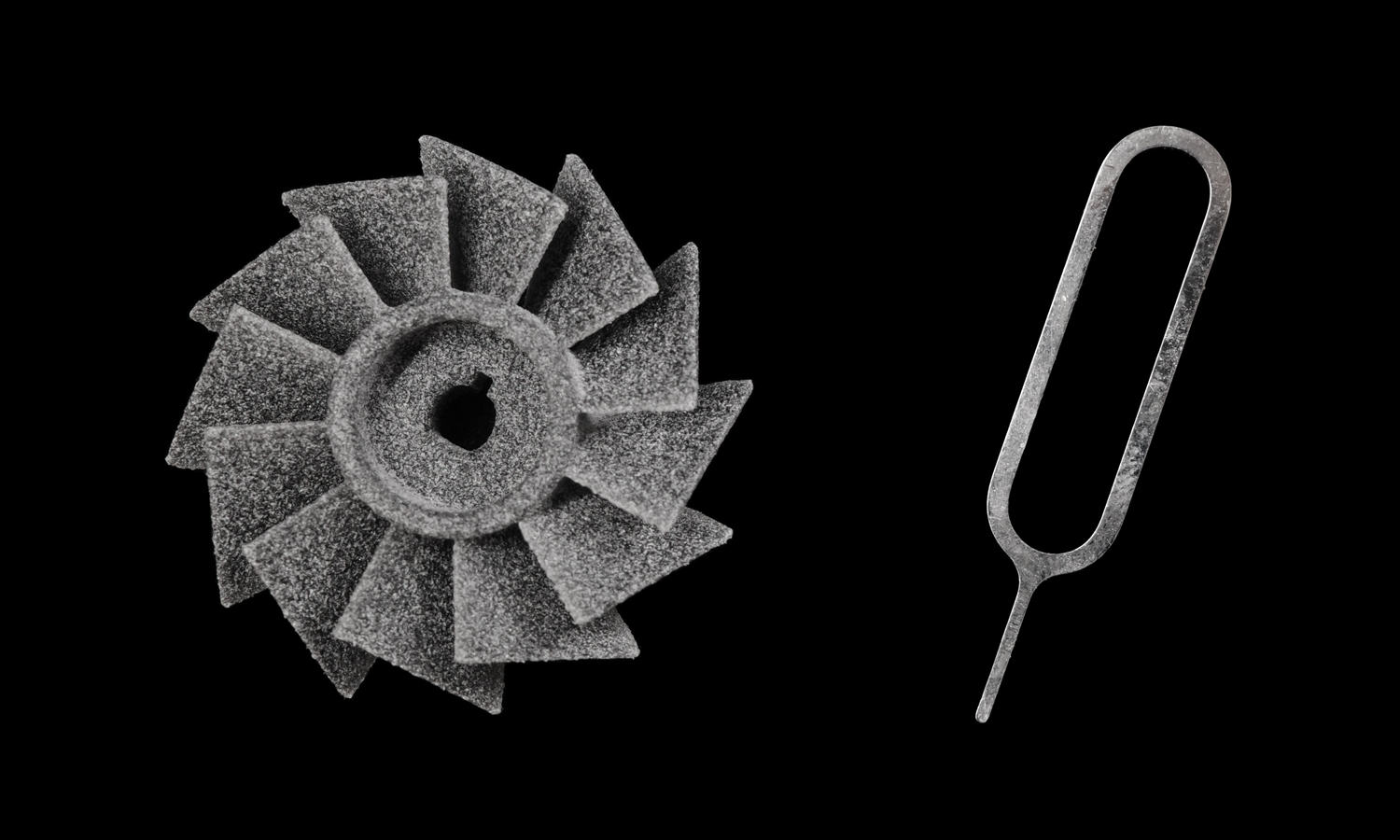

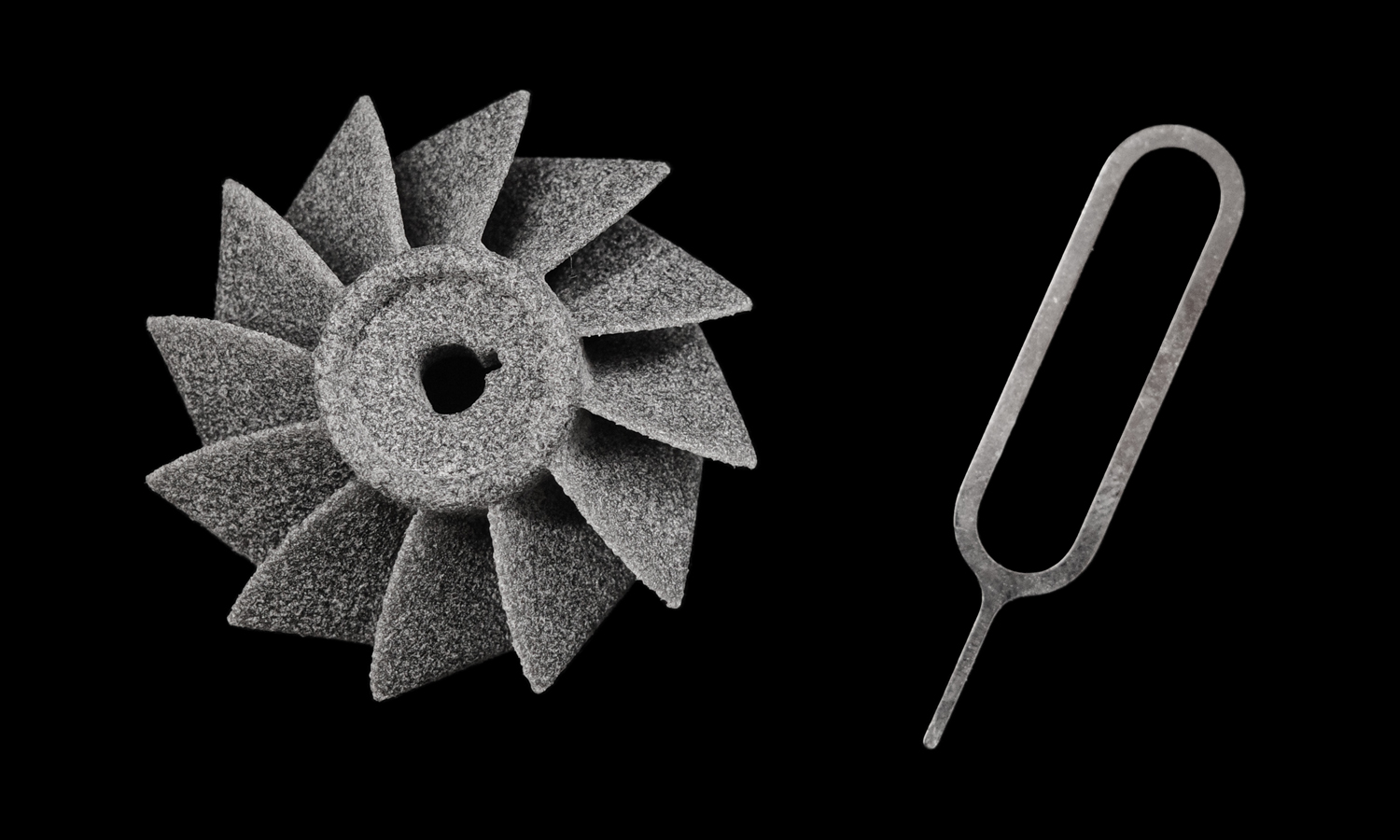

Are you looking for a way to create realistic and durable propeller miniatures for your hobby or project? If so, you might want to consider MJF 3D printing as an option. MJF stands for Multi Jet Fusion, a 3D printing technology that uses a fine powder and a thermal inkjet array to fuse layers of material together. MJF 3D printing offers several advantages over other 3D printing methods, such as:

High resolution and accuracy: MJF 3D printing can produce complex geometries and fine details with a layer thickness of 120 microns and a dimensional accuracy of +/- 0.6%.

High strength and durability: MJF 3D printed parts have excellent mechanical properties, such as tensile strength, elongation, and impact resistance. They can withstand harsh environments and repeated use without breaking or deforming.

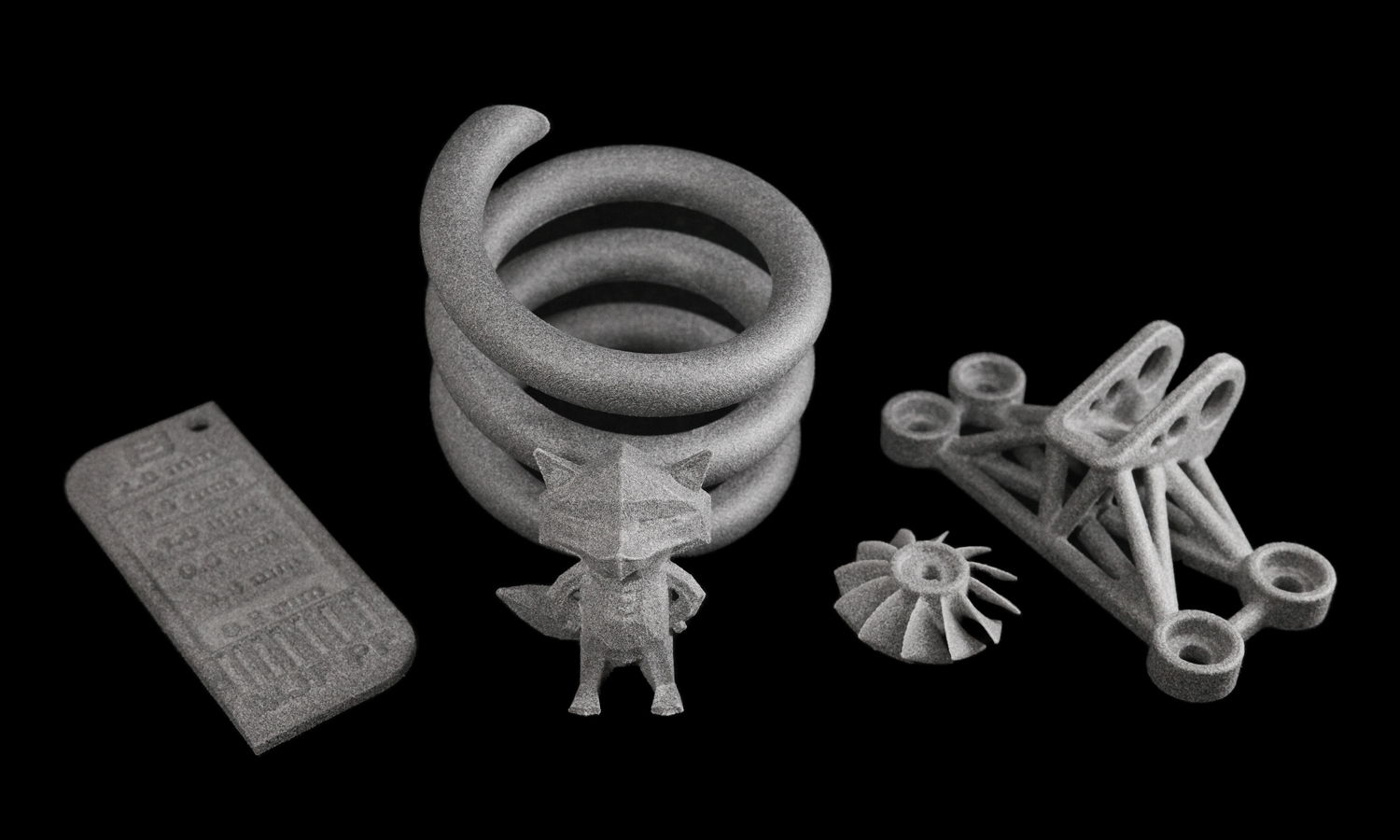

High versatility and functionality: MJF 3D printing can print with different materials, such as nylon, polypropylene, or TPU. Each material has its own characteristics and applications, such as chemical resistance, flexibility, or elasticity. MJF 3D printed parts can also be post-processed with various methods, such as dyeing, painting, or polishing.

One of the most suitable materials for propeller miniatures is polypropylene (PP).В PP is a thermoplastic polymer that has superior resistance to chemicals, low-moisture absorption, and high rigidity.В PP is ideal for applications like piping, fluid systems, and containers.В PP also has a great surface finish that resembles injection molding.

This propeller miniature was printed by FacFox, a leading online platform for 3D printing services. FacFox offers high-quality MJF 3D printing with competitive prices and fast delivery. You can upload your 3D model to their website and get an instant quote. You can also choose from various options for materials, colors, and post-processing. FacFox will print your propeller miniature with the best MJF 3D printers and ship it to your door in no time.

If you are interested in MJF 3D printing or want to learn more about it, visit FacFoxвҖҷs website today. You will find a wealth of information and resources on MJF 3D printing technology, materials, and applications. You will also discover how FacFox can help you turn your ideas into reality with MJF 3D printing. DonвҖҷt miss this opportunity to create amazing propeller miniatures with MJF 3D printing and FacFox!

Solution

The manufacturing process of MJF 3D Printed PP Propeller Miniature with Raw Finish was as follows:

- Step 1: A 3D model of the propeller miniature was uploaded to FacFoxвҖҷs website and an instant quote was obtained.

- Step 2: A build unit with a bed of polypropylene (PP) powder was inserted into the MJF 3D printer.

- Step 3: A layer of PP powder was spread across the build platform and pre-heated to a temperature below its melting point.

- Step 4: A fusing agent and a detailing agent were selectively applied to the powder layer using a thermal inkjet array. The fusing agent marked the areas where the powder would be fused together, while the detailing agent improved the surface quality and resolution of the part.

- Step 5: An infrared lamp passed over the powder layer and heated it to a temperature above its melting point. The areas with the fusing agent melted and bonded together, while the areas without the agent remained in powder form.

- Step 6: The build platform was lowered and another layer of PP powder was spread and pre-heated. The process of applying agents and heating was repeated until the propeller miniature was completed.

- Step 7: The build unit was removed from the printer and transferred to a processing station, where it was cooled down and cleaned of excess powder.

- Step 8: The propeller miniature was retrieved from the build unit and inspected for quality and accuracy. No post-processing was required for the raw finish.