- SLA 3D Printed Dark Tough Resin Panel Fine Polished

- CNC Milled and Polished Mercedes-Benz Hood Ornament Customization

Gallery

About Project

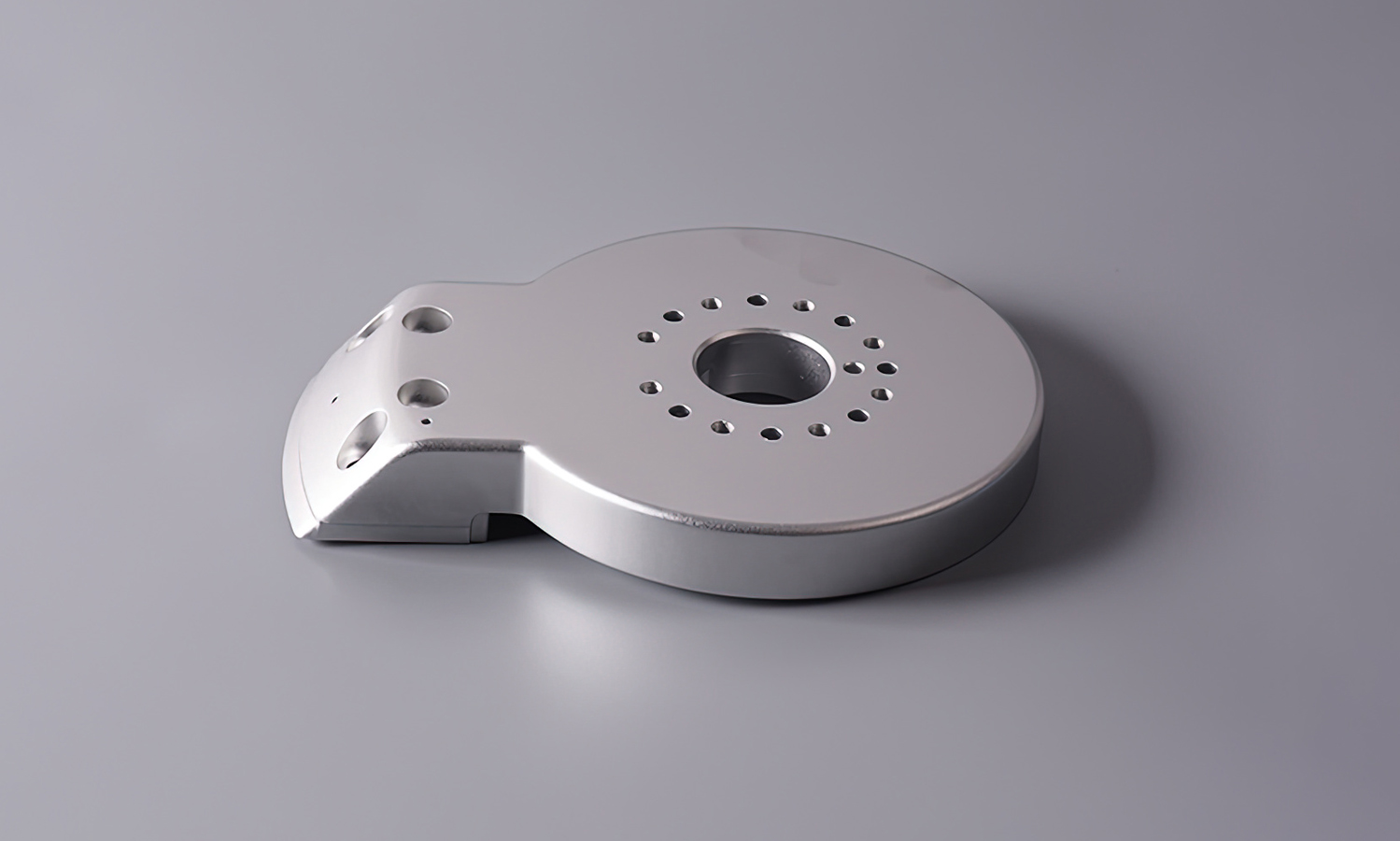

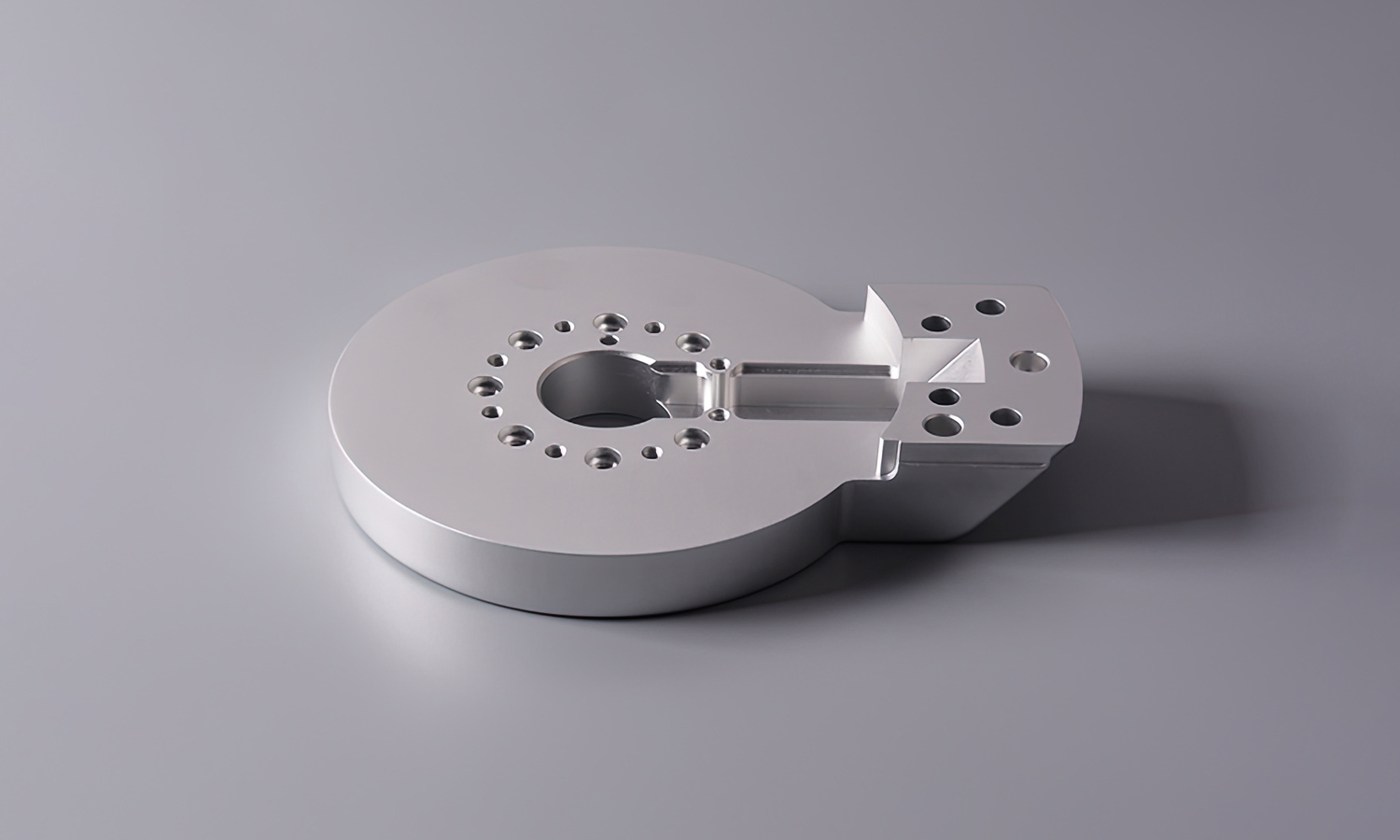

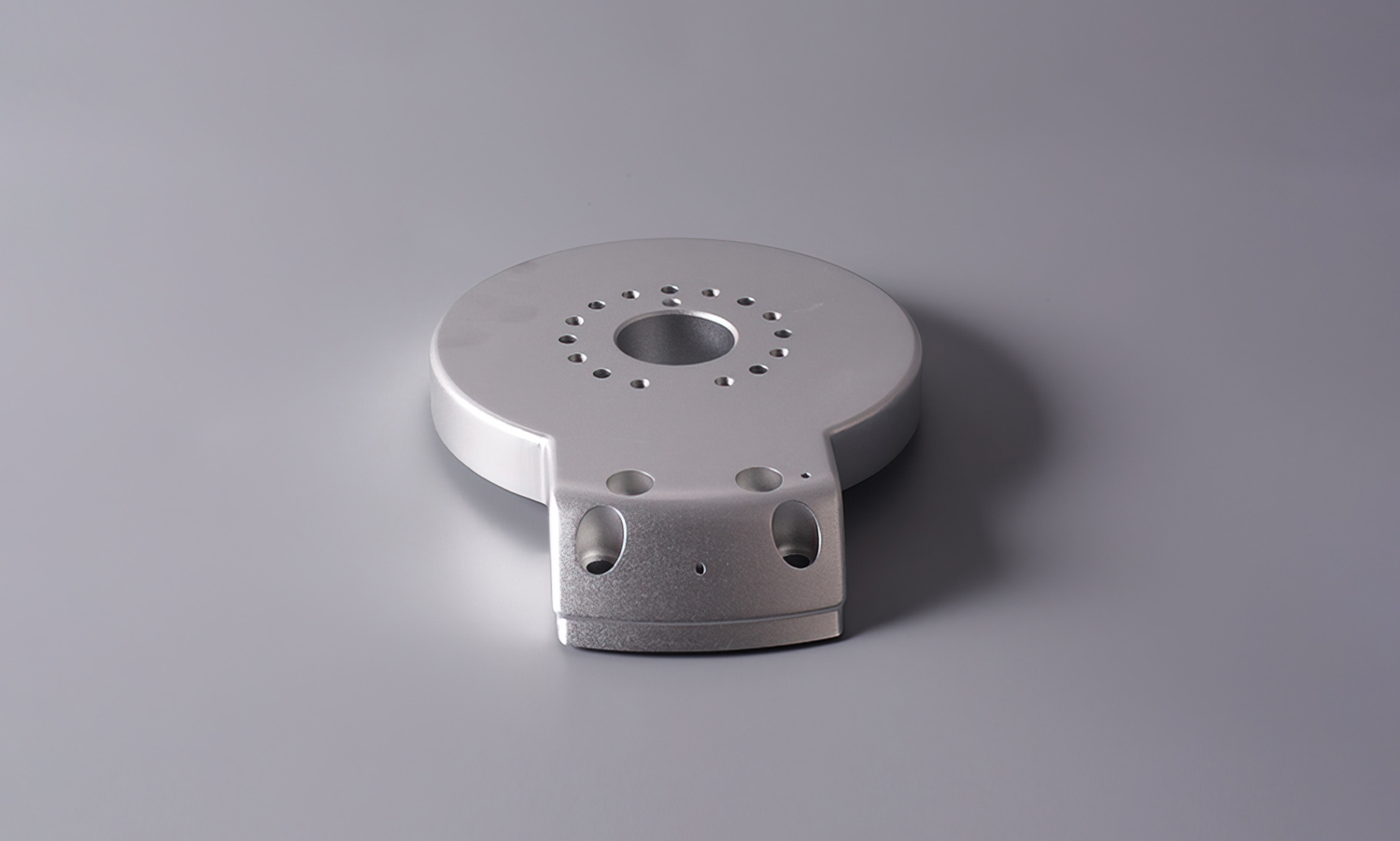

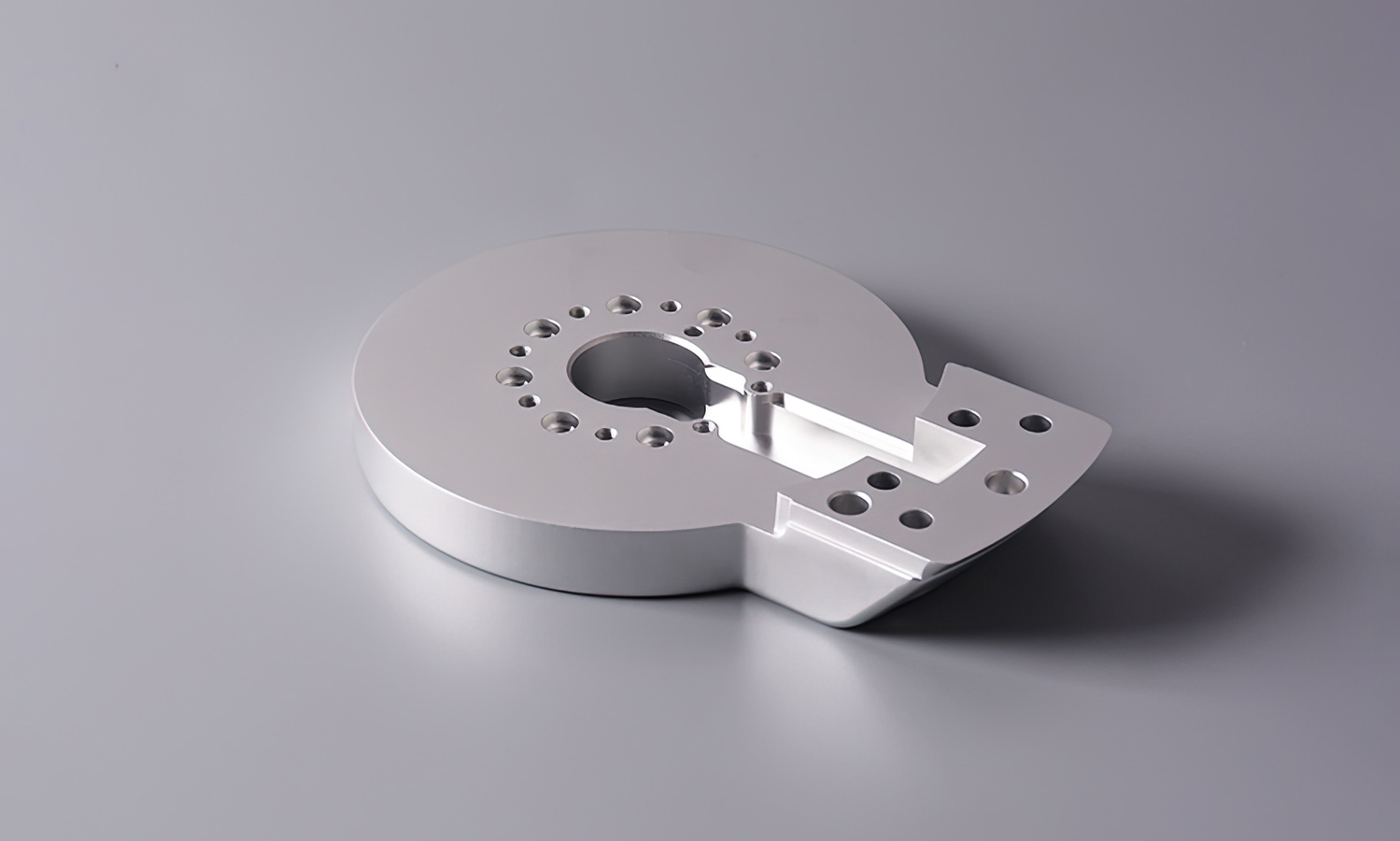

The aluminum modular plate is made by using a CNC milling machine, which is a subtractive manufacturing process that removes material from a block of metal or plastic. CNC milling can create complex shapes and precise holes with accuracy and speed.

Our product features drilled holes that are formed by using a rotating cutting tool called a drill bit. Drilled holes can be refined by using other processes such as reaming, boring, and circular interpolation with an end mill. These processes can improve the surface finish, diameter tolerance, and concentricity of the holes.

If you are looking for a reliable and affordable CNC milling service, you should check out FacFox. FacFox is an online platform that connects you with professional CNC machinists who can produce your parts quickly and efficiently. You can upload your 3D model, choose your material and finish options, and get an instant quote for your order. FacFox also offers quality assurance, fast delivery, and customer support for your CNC milling projects.

Whether you need prototypes or production parts, FacFox can help you with CNC milling. Visit our website today and get started on your next project!

Solution

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped and the holes were drilled automatically. It would be inspected during and after the machining process for quality assurance.