- DLP 3D Printed Ceramic Round Pieces with Geometric Patterns

- FDM 3D Printed Large Scale Clear Outdoor Chairs

Gallery

About Project

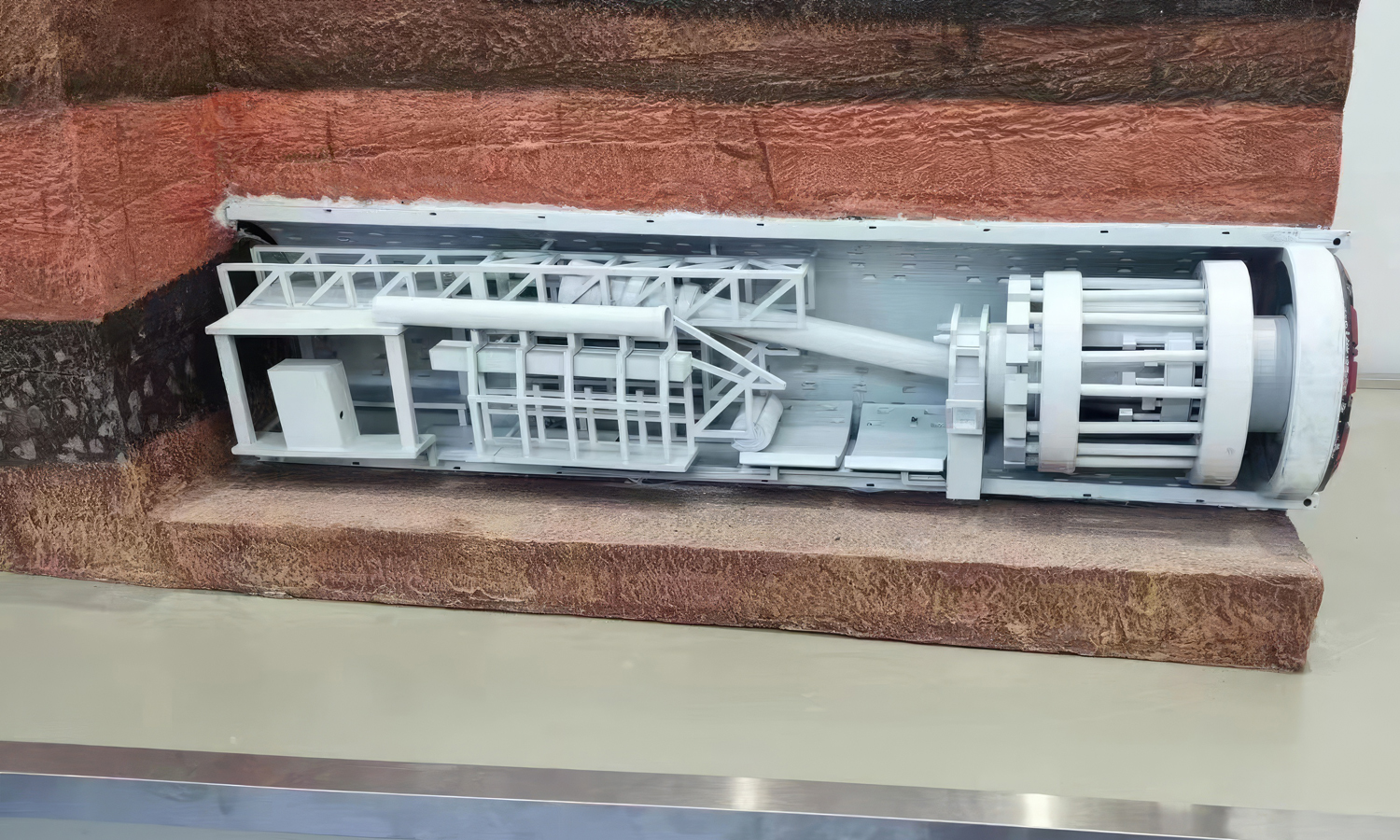

Imagine a behemoth, 8 meters long and 1 meter high, meticulously crafted to showcase the marvel of subterranean construction. This isn't a scene from science fiction; it's a reality we helped bring to life at FacFox through the power of SLA 3D printing.

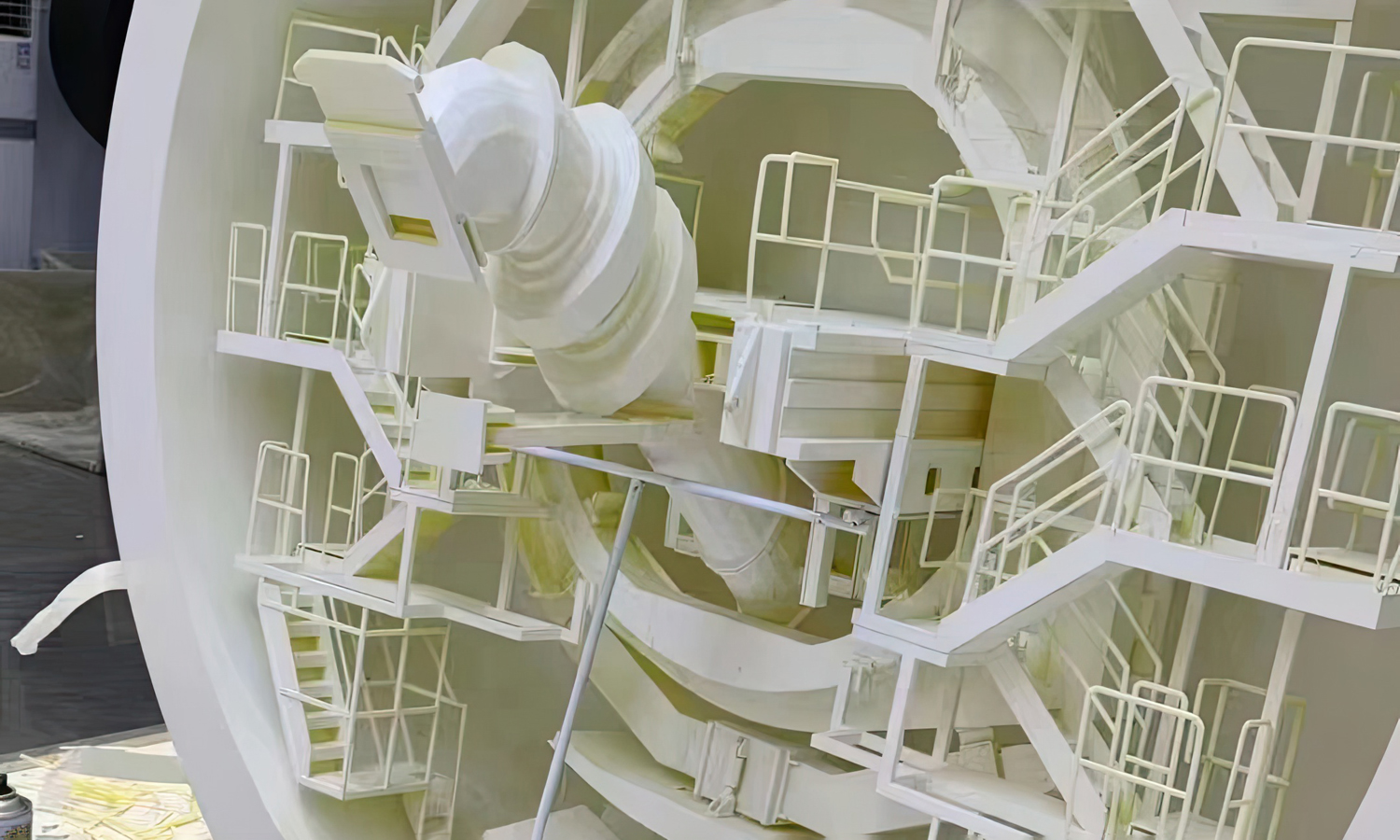

A leading development company, entrusted with building subway lines in a bustling metropolis, approached us with a unique challenge: creating a large-format display model of a Tunnelling Shield Machine (TSM). This colossal machine is the workhorse behind underground excavation, carving a path for new subway lines beneath the city. The model, envisioned to be a centerpiece display, would illustrate the entire tunnelling process.

The sheer size of the project presented the first hurdle. To ensure precision and maintain fidelity to the real TSM, the model needed to be split into manageable sections for printing. This meticulous process demanded perfect alignment during the post-printing assembly stage, where the individual parts were meticulously joined using specialized nails and glue.

Another challenge arose from the intricate design of the TSM itself. The machine features numerous overhang structures, which can be tricky for 3D printing. To overcome this obstacle, our team strategically bolstered these sections and added necessary supports during the printing process. This ensured the final model captured the intricate details of the real machine without compromising structural integrity.

The final product is a testament to the power of SLA 3D printing for large-format display models. The colossal model stands as a captivating representation of the engineering marvel behind modern subway construction. It not only serves as an informative display but also ignites awe and inspires a deeper appreciation for the complex world beneath our feet.

Looking to create a showstopping large-format display model for your next project? FacFox offers cutting-edge SLA 3D printing solutions specifically tailored for large-scale models. Our expertise in handling complex geometries and meticulous attention to detail ensure your vision is brought to life with stunning precision. Contact FacFox today and let us turn your grand ideas into reality.

Solution

- Step 1: Designing. The 3D model of the tunneling shield machine was meticulously designed by engineers, ensuring all details were accurate to represent the subway construction process.

- Step 2: Slicing.┬ĀThe large model was then sliced into smaller sections using specialized software, which allowed for the creation of manageable print files that the SLA 3D printer could interpret.

- Step 3: Printing Preparation.┬ĀSupports for overhang structures were added to the design to ensure stability, and the parts were oriented to optimize the printing process and minimize the need for post-processing.

- Step 4: Printing Process. Each section of the model was printed separately. The SLA 3D printerŌĆÖs laser cured the liquid SLA ABS-like Resin layer by layer, building the parts from the bottom up.

- Step 5: Post-Processing.┬ĀAfter printing, the parts were washed to remove any uncured resin. They were then cured in a UV chamber to achieve the final hardness and strength required for assembly.

- Step 6: Assembly.┬ĀThe printed parts were carefully aligned and glued together. Precision was key during this step to ensure that the final model accurately represented the original design.

- Step 7: Finishing Touches.┬ĀAdditional supports were removed, and the model was sanded to smooth out any seams or rough edges. The model was then painted and detailed to enhance its visual appeal and realism.

- Step 8: Quality Check.┬ĀThe completed model underwent a thorough quality check to ensure that all parts were correctly aligned, securely attached, and that the model met all the specifications provided by the development company.