- SLM 3D Printed Die Steel Desktop Ornament

- SLA 3D Printed Large-format Tunnelling Shield Machine Display Model

Material Porcelain

Quantity 12 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

DLP 3D printing technology opens a new world of possibilities for creating unique and intricate ceramic pieces. At FacFox, we're excited to offer our expertise in DLP ceramic printing, allowing you to bring your ceramic design visions to life with stunning precision.

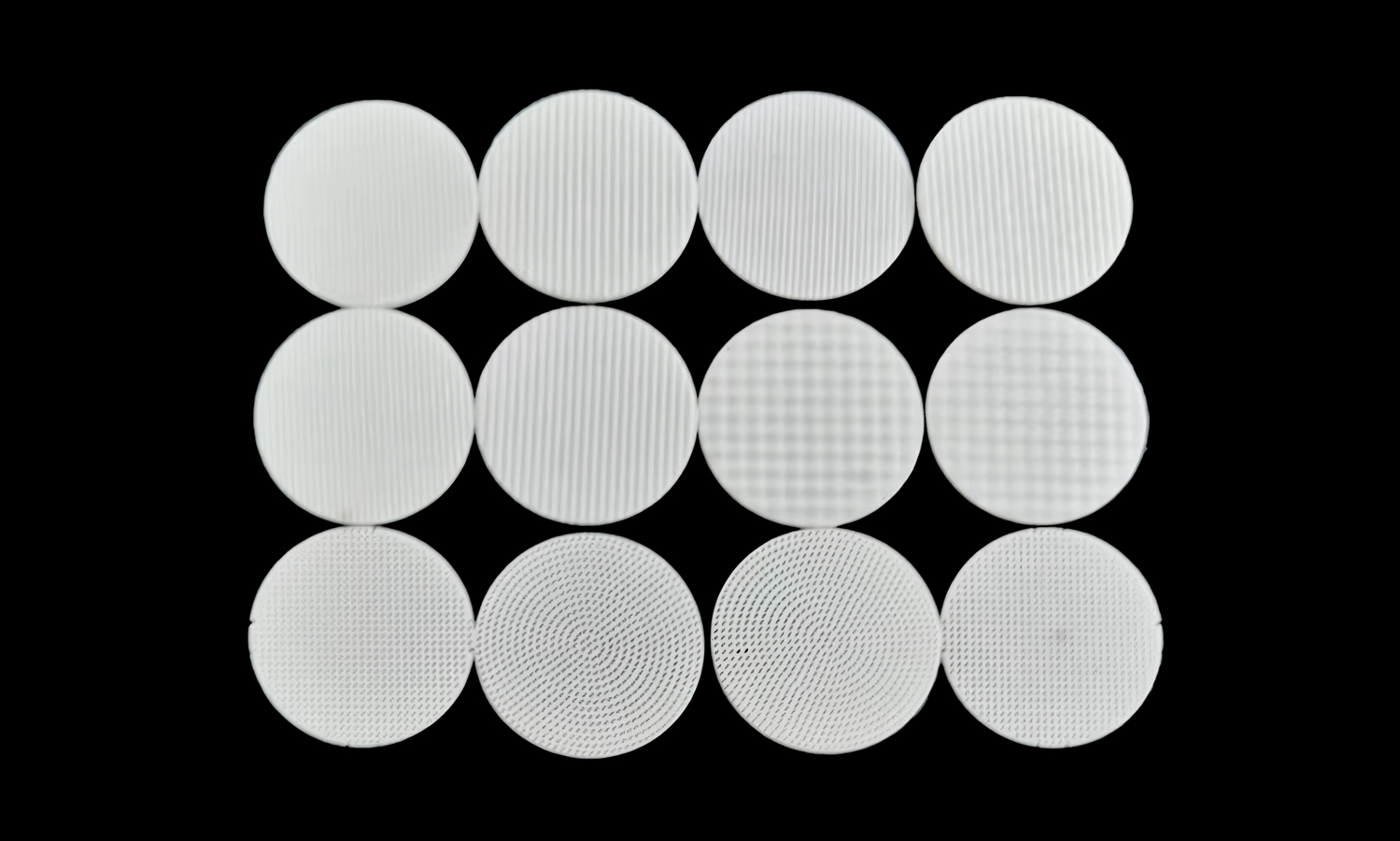

Imagine a set of smooth, round ceramic pieces adorned with delicate geometric patterns. With DLP printing, we can create these pieces with exceptional detail, ensuring every stripe, pore, and wave is flawlessly reproduced.

Here's a glimpse of the variety achievable:

- Stripes: We can create pieces with both thin and thick stripes, offering a touch of modern elegance to your design.

- Concentric Circles: Pieces can be adorned with pores arranged in concentric circles, adding a touch of whimsy and texture.

- Crossing Pores: A more intricate design can be achieved with pores arranged in a crossing pattern, creating a visually captivating effect.

- Regular Waves: Want a calming and organic feel? We can produce pieces with smooth, regular wave patterns.

The high resolution of DLP printing ensures that even the most intricate pores are printed successfully, resulting in a flawless final product. These ceramic pieces are perfect for a variety of applications, from decorative objects and tableware to architectural elements and even functional prototypes.

Bring your vision to life with FacFox's DLP ceramic printing services. We offer exceptional detail, precision, and a wide range of design possibilities. Contact us today to discuss your project and get started!

Solution

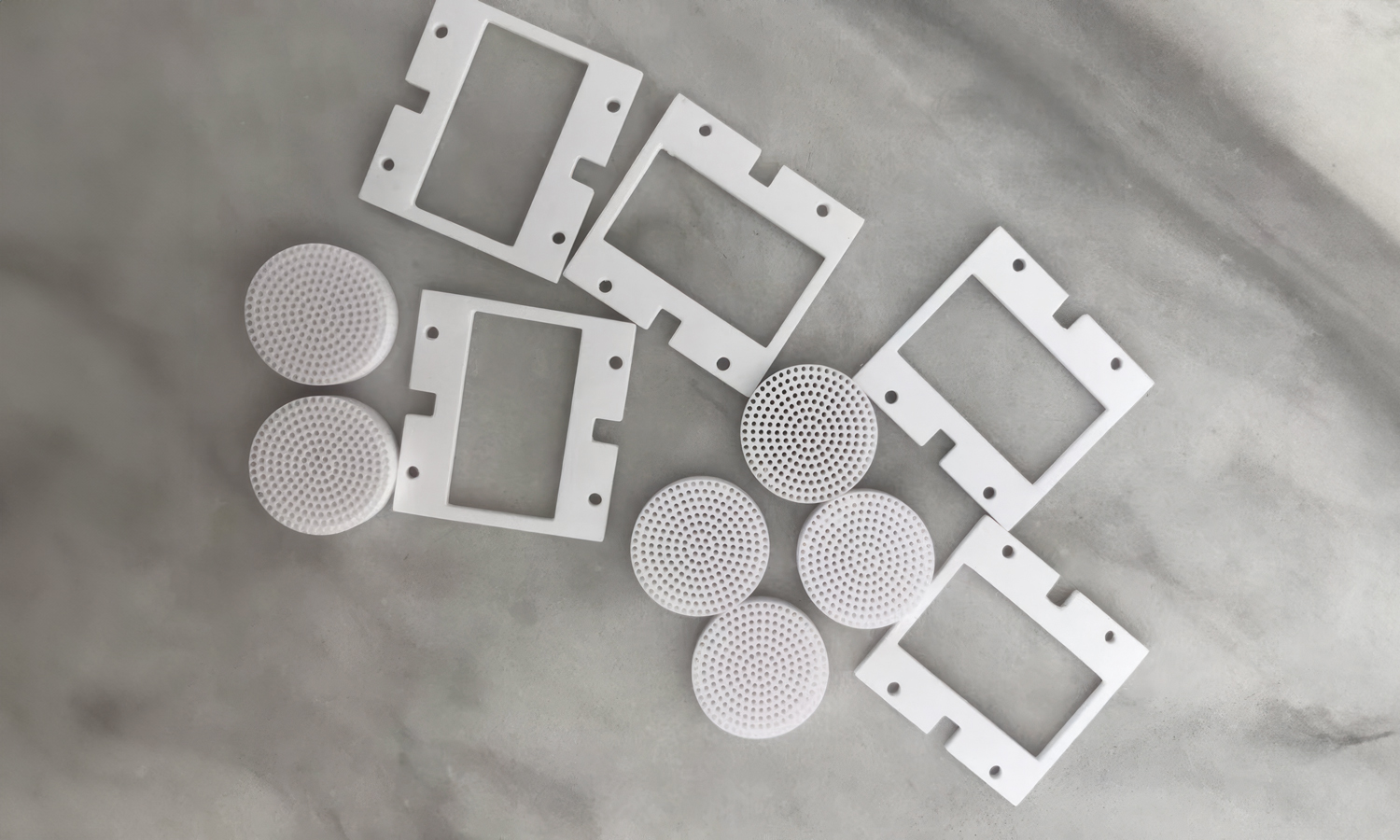

- Step 1: Design and Preparation. Initially, digital models of the round pieces with the desired geometric patterns were created using computer-aided design (CAD) software. The designs included variations such as thinner and thicker stripes, pores arranged in concentric circles, crossingly arranged pores, and regular wave patterns.

- Step 2: Resin Preparation. A ceramic resin, composed of photopolymerizable monomers, ceramic powders, and photoinitiators, was then prepared. The mixture was homogenized to ensure a smooth consistency, crucial for achieving high-resolution prints.

- Step 3: Printing Process. The DLP 3D printer was set up with the prepared resin. High-resolution settings were selected to accurately render the intricate details of the pores and patterns.

- Step 4: Layer-by-Layer Fabrication. The DLP device projected UV light onto the resin surface, curing and solidifying it layer by layer. The build platform was lowered incrementally after each layer, allowing new resin to flow over the previously cured layer.

- Step 5: Debinding. After the printing was completed, the green bodies of the ceramic pieces were subjected to a debinding process. The organic components were carefully removed, leaving behind a porous ceramic structure.

- Step 6: Sintering. The debound pieces were then placed in a high-temperature furnace for sintering. The temperature was gradually increased to just below the ceramic’s melting point, causing the particles to fuse together and densify the structure.

- Step 7: Post-Processing. Once sintered, the ceramic pieces were allowed to cool down slowly to room temperature. Any additional post-processing, such as surface smoothing or finishing, was performed to enhance the aesthetic and functional qualities of the pieces.

- Step 8: Quality Control. Finally, the finished pieces were inspected for any defects. The high resolution of the DLP printing process ensured that all pores and patterns were printed successfully, resulting in smooth surfaces and precisely rendered geometric designs.