- SLA 3D Printed and Painted Machine Resin Scaled-down Model

- DLP 3D Printed Ceramic Round Pieces with Geometric Patterns

Gallery

About Project

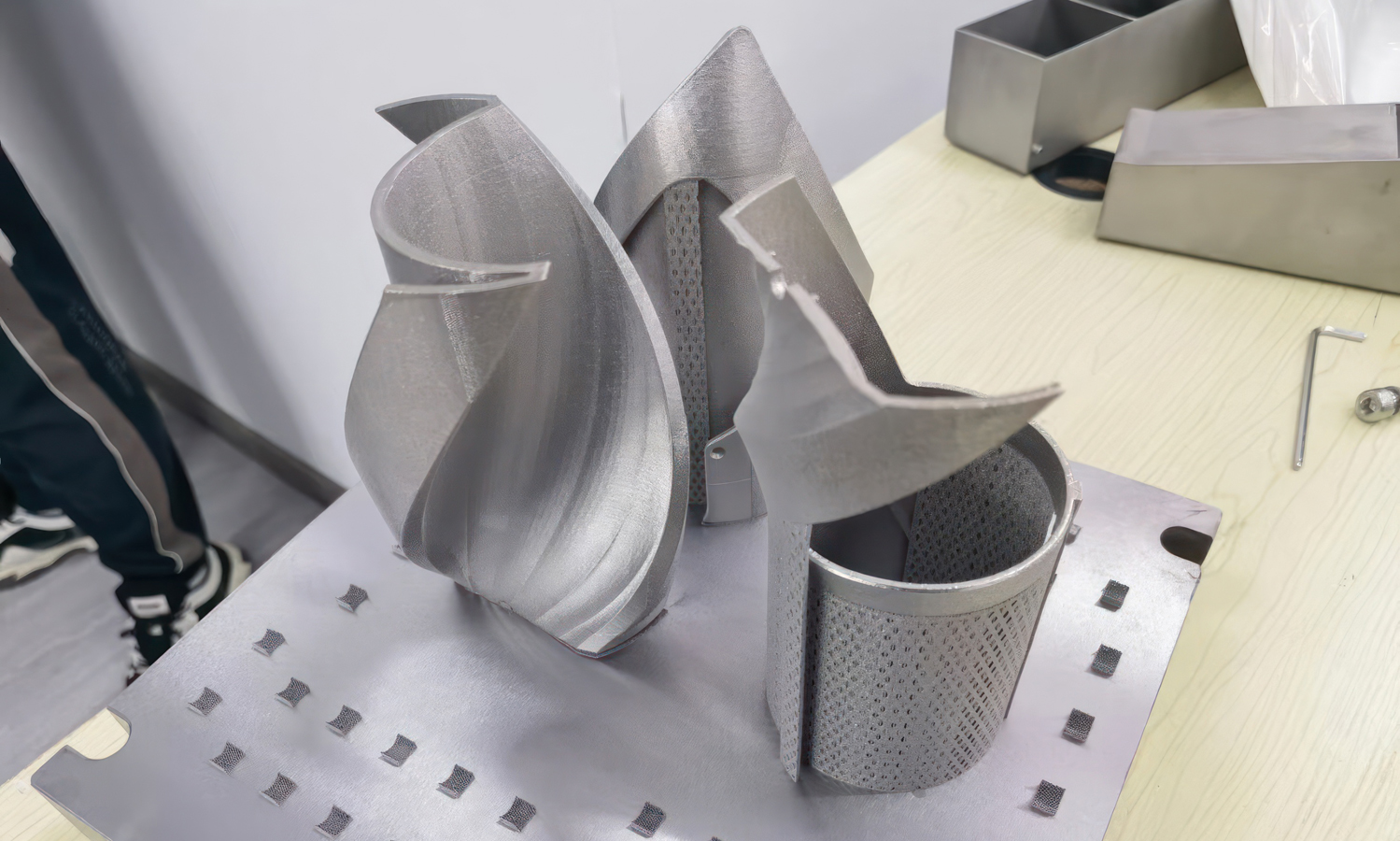

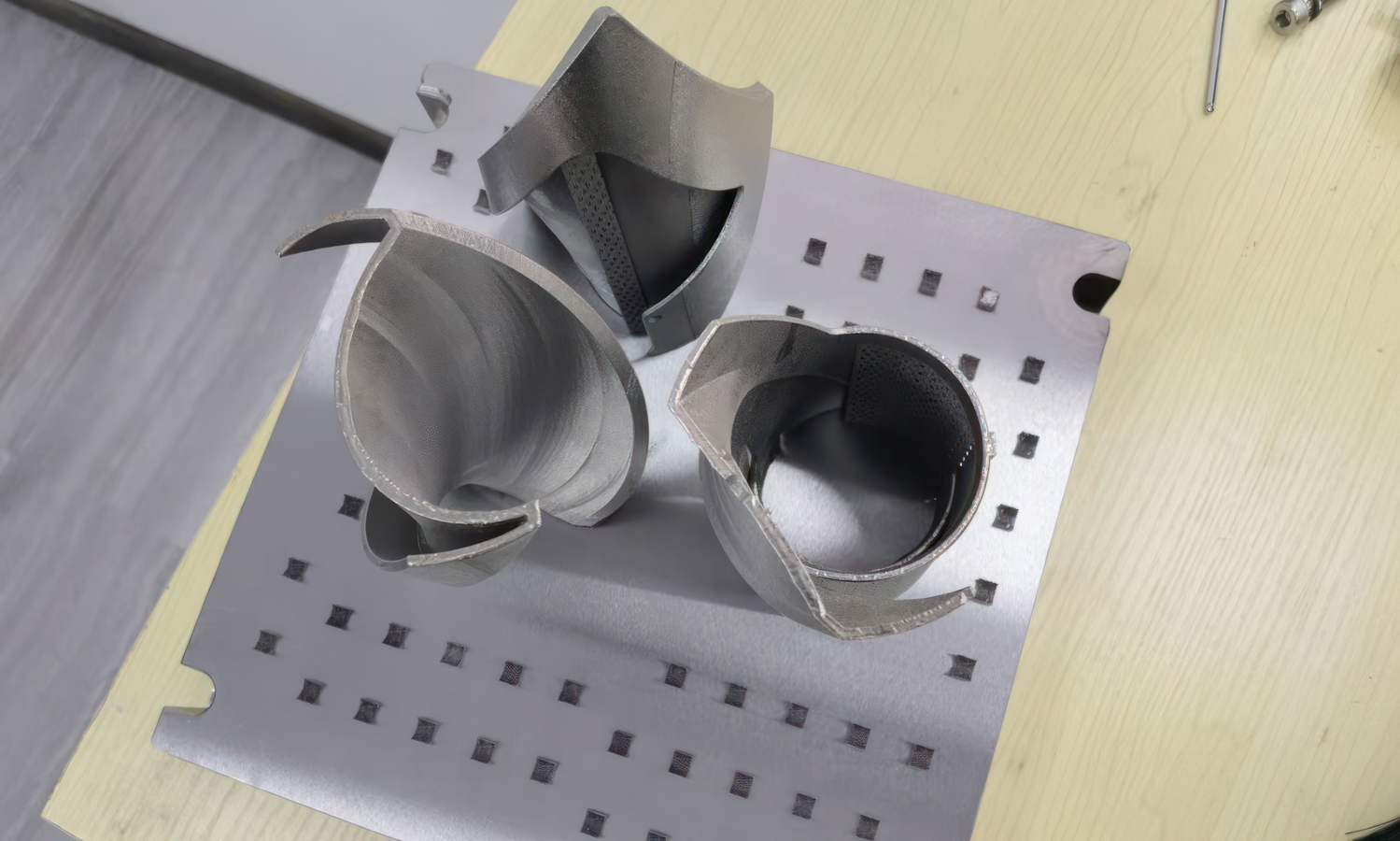

This eye-catching desktop ornament showcases the beauty and potential of SLM 3D printing for metalworking applications. The intricate design features three curved shapes, resembling curled pieces of paper frozen in mid-motion. One of these shapes bends gracefully into a tube, adding a touch of dynamism to the piece. The surfaces are adorned with a grid pattern, creating a subtle industrial aesthetic.

But the true marvel lies in the material itself. This ornament is crafted from die steel, a high-strength material commonly used in metal stamping tools. The SLM 3D printing process allows for the creation of complex geometries in die steel, making it possible to produce this unique and functional design.

The base of the ornament serves a clever dual purpose. It features a series of small supports that can hold 3D-printed die-steel bottle openers, transforming the ornament into a display for these custom-made gifts. This thoughtful detail highlights the versatility of SLM 3D printing for metal and its ability to produce both decorative and functional objects.

This SLM 3D printed die steel ornament is a remarkable example of how metal additive manufacturing can be used to create unique and functional pieces. It's a testament to the precision and versatility of SLM 3D printing technology.

If you're looking to explore the possibilities of SLM 3D printing for your own metalworking projects, FacFox is here to help. With extensive experience and expertise in metal additive manufacturing, FacFox can provide you with high-quality 3D printing services and support you throughout the entire process, from design optimization to production. Visit FacFox today to discuss your metal 3D printing needs and bring your innovative ideas to life.

Solution

- Step 1: Designing: A digital model of the desktop ornament was designed using CAD software. The design included three figures resembling dancing curling papers, with one figure curled into a tube. Hollowed grid patterns were incorporated into the figures, and small supports were integrated into the board to hold the die steel bottle openers.

- Step 2: File Preparation: The CAD model was then processed, and an STL file was generated. This file was sliced into thin horizontal layers, preparing it for the SLM printing process.

- Step 3: Material Selection: Die steel powder was selected for its properties that are conducive to SLM printing and its suitability for creating detailed and durable objects.

- Step 4: Printing: The SLM printer was set up, and the die steel powder was evenly distributed on the build platform. A high-power laser sintered the powder, building the ornament layer by layer.

- Step 5: Post-Processing: After the printing was completed, the supports were carefully removed. The ornament underwent heat treatment to relieve internal stresses and to enhance its mechanical properties.

- Step 6: Surface Finishing: Subsequently, the ornament was subjected to surface finishing techniques to refine the grid patterns and smooth the intricate curves.

- Step 7: Quality Inspection: The completed ornament was inspected to ensure it met the precise specifications and quality standards required by the metal material company.

- Step 8: Delivery: Finally, the customized SLM 3D printed die steel desktop ornament was delivered to the metal material company, ready for display or to be presented as gifts.