Resin-based vat polymerization 3D printers are becoming increasingly popular, but what exactly do you call these technologies? Let’s make sense of this.

SLA, DLP, LCD: A Naming Conundrum

Resin 3D printing is, in 3D printing years, rather old. The first patented resin-based 3D printing technology came in 1986 with Charles “Chuck” Hall’s invention of stereolithography (SLA). He sought to cure photosensitive polymer resins with UV light, layer by layer.

Since then, improvements have been made, patents have expired, and competitors have joined the market. Now, resin-based 3D printers range from affordable hobbyist tools to professional, industrial machines. But with this democratization has come an overwhelming and confusing wave of names for these resin technologies: SLA, DLP, mSLA, and LCD, to name a few.

With everyone marketing their machines in their own ways, how can you make sense of what you’re buying?

International Standard

The ISO/ASTM 52900:2015 International Standard: that’s a lot of words, but trust us, it will make everything easier to understand.

For almost anything, from thread specifications to quality standards, the International Organization for Standardization (ISO) has a well-respected set of reference standards that define terms and principles. This is especially important in industrial spheres, where communicating with the same vocabulary and expectations is key to efficiency.

With respect to 3D printing, one of the biggest sources of confusion is whether all resin-based printing should be called “stereolithography”. After all, it was the first technology. Luckily for us, ISO/ASTM 52900:2015 draws a clear line.

All resin-based 3D printing, in which a liquid photopolymer resin is stored in a vat (as opposed to being ink-jetted through a nozzle), is collectively known as vat polymerization. All other names, such as SLA, DLP, or LCD, are subcategories of this technology.

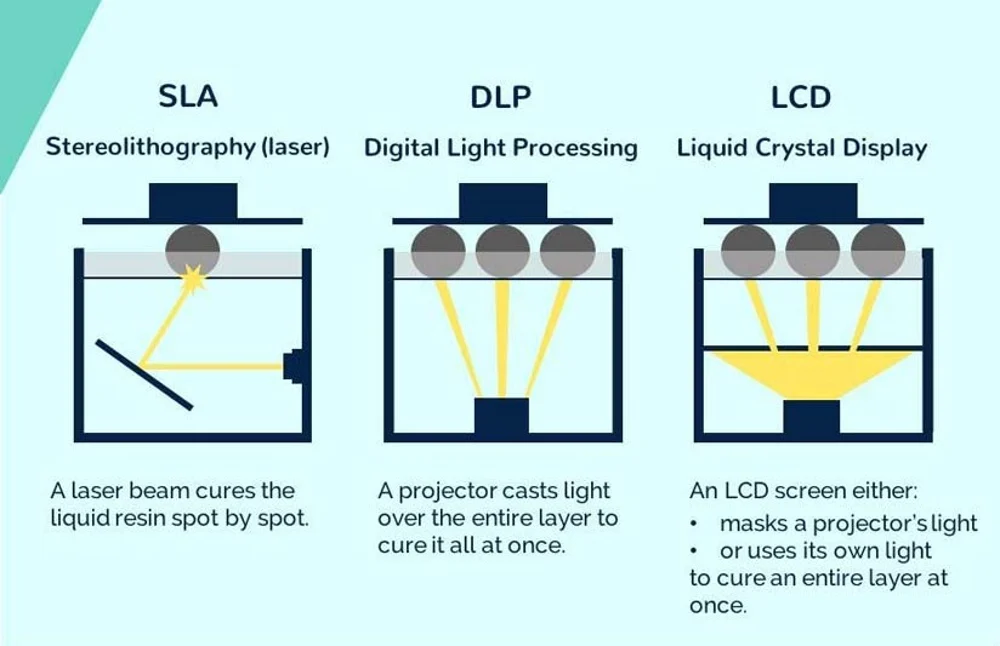

So, what differentiates the three most common forms of vat polymerization?

SLA

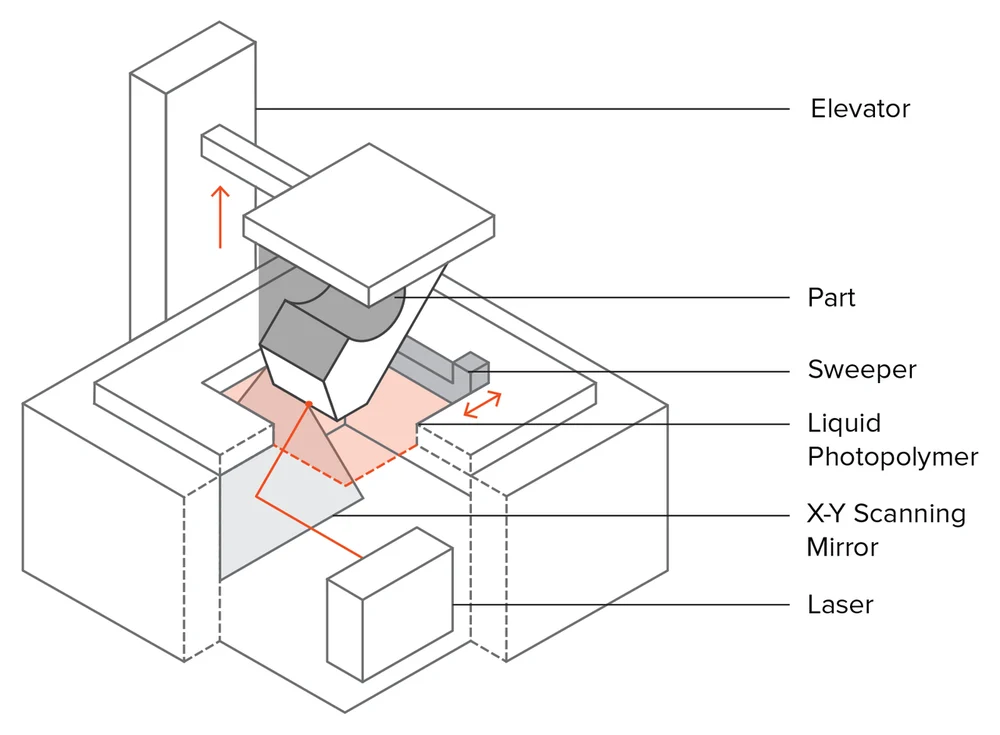

Like other vat polymerization technologies, SLA cures photosensitive resin in layers to form 3D objects. We explore SLA in-depth in our dedicated guide, so we’ll just clarify what makes SLA unique.

SLA’s UV light source is a laser, precisely controlled by rotating mirrors to “draw” out each layer being printed.

The main advantages of this method are higher precision and better print quality, as the precise motion and tiny size of the laser allow for finer detail and resolution. This improved quality comes at the price of print speed, as drawing out each layer can be more time-consuming.

DLP

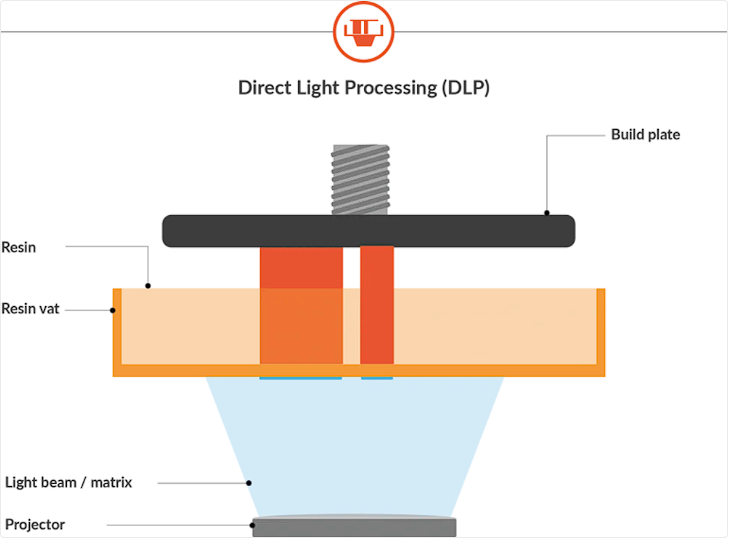

Digital light processing (DLP) uses a different UV light source. Instead of lasers, DLP printers have UV projectors, which work by using micromirrors to control the projected light. The cross-sections of each layer are projected in a single go, curing everything in the layer at once.

With this, you lose resolution compared to SLA, and the projectors used can be bulky and expensive. What you do get, though, is much better print speed, as an entire layer can be cured at once.

LCD & LCD Masking

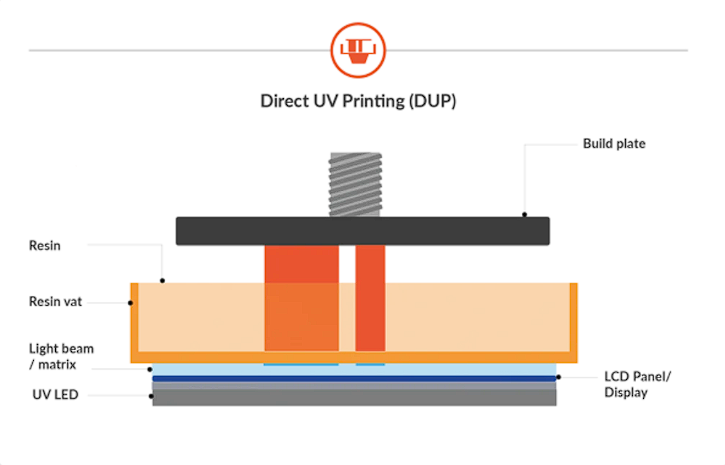

LCD vat polymerization is the newcomer on the block, and is perhaps the greatest source of confusion. Even the diagram above calls it by a separate name (DUP). You might also hear “LCD shadow masking”, “mSLA”, or similar names.

At their cores, all LCD 3D printers operate on the same principle: they shine cross-sections of your 3D prints by using an LCD screen to mask off a UV light source. Essentially, this replaces the projector setup of DLP and replaces it with a more compact and inexpensive screen, at the expense of printing resolution and printer durability. Indeed, the LCD screen can wear out over time, while a DLP projector will stay good for much longer.

With LCD printing, you get the speed that comes with DLP, but you also reap the benefits of a lighter, smaller, and more affordable machine.

Final Thoughts

Hopefully, we were able to help you quickly differentiate between the various resin 3D printing technologies.

With this newfound knowledge, please be aware that not everyone will use this same set of vocabulary, as you briefly had a taste of in the LCD section. In the real world, marketing and accidental misuse will have these words used in interchangeable and often contradictory ways. What’s important is to have an understanding of what to look for and a clear way of identifying the various technologies.

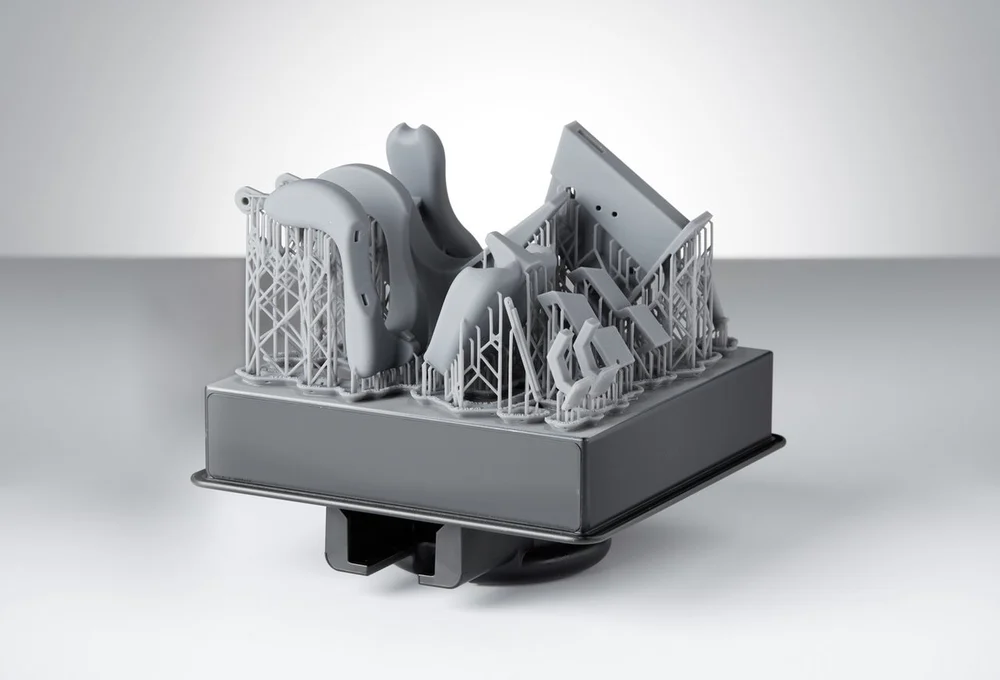

(Lead image source: Formlabs)