As in laser or inkjet printers, the resolution of a 3D printer is an indicator of its printing quality. However, when we talk about resolution in 3D printing, we have to take all 3 dimensions into consideration: resolution along the X and Y axis, and resolution along the Z-axis.

Don’t miss: 3D Printing Speed: How Fast Can 3D Printers Go?

3D Printer Resolution: Facts and Figures

Horizontal resolution (or XY resolution) is the smallest movement the printer’s extruder can make within a layer on the X and the Y axis. The lower the value, the higher the details the printer produces.

Vertical resolution (or layer thickness or layer height) is the minimal thickness of a layer that the printer produces in one pass. The smaller the layer thickness, the smoother the printed surface will be. However, the printing process will take longer for finer layers as the printer has to produce more layers.

Typical consumer FDM printers have a layer thickness of 0.2 or 0.3 mm. One of the top desktop models at the moment, the Ultimaker 2 (more in All3DP’s review of the Ultimaker 2 Extended), even boasts a vertical resolution of 0.02 mm. SLA printers such as the Form 2 produce layers as thin as 0.025 mm.

3D Printing Quality Depends on the Method Used

Simply comparing figures, however, is only valid when you compare printers using the same technology, FDM printers for example. It does not work when you compare FDM printers to SLA printers. In this case, it is the printing method and the material used that make the difference.

In FDM 3D printers, resolution is a factor of the nozzle size and the precision of the extruder movements on the X and Y axis. The precision and smoothness of the printed models is also influenced by other factors: The bonding force between the layers is lower than in SLA printing, and the weight of upper layers may squeeze the layers below. As a result, a number of problems may compromise print quality (for more details see All3DP’s article on common 3D printing problems).

Also note: The width of the filament used for FDM printing does not influence XY resolution. Plastic filament is available in two widths: 1.75 mm or 3 mm. The printer nozzle is much finer: The nozzle size in the Ultimaker 2, for example, is 0.8 mm.

SLA 3D printers produce objects of higher resolution and are more accurate than FDM printers. SLA 3D printing resolution is determined by the optical spot size either of the laser or the projector. In the Form 2, spot size is 140 microns (0.14mm), in its predecessor, the Form 1+, it’s 155 microns – that is a completely different league compared to the 0.8 mm nozzle size of the Ultimaker. Furthermore, less force is applied to the model during printing, which also results in much smoother surface finish. SLA prints show details a FDM printer could never produce.

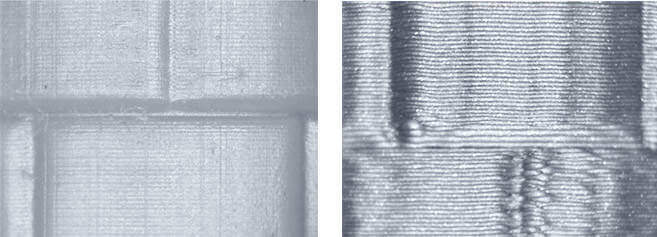

A direct comparison between a FDM and a SLA printers reveals that SLA printers produce much finer details, even if you set them to the same vertical resolution as a FDM printer:

The photograph of the printed parts at the top of the articles was provided by Formlabs; the parts were 3D printed on a Form 2 SLA printer.