- SLS 3D Printed Flanged Housing Nylon Gasket with Cylindrical Bores

- SLS 3D Printed 40mm Valve Adaptor Pipe Plug with Formlabs Nylon PA12

Gallery

About Project

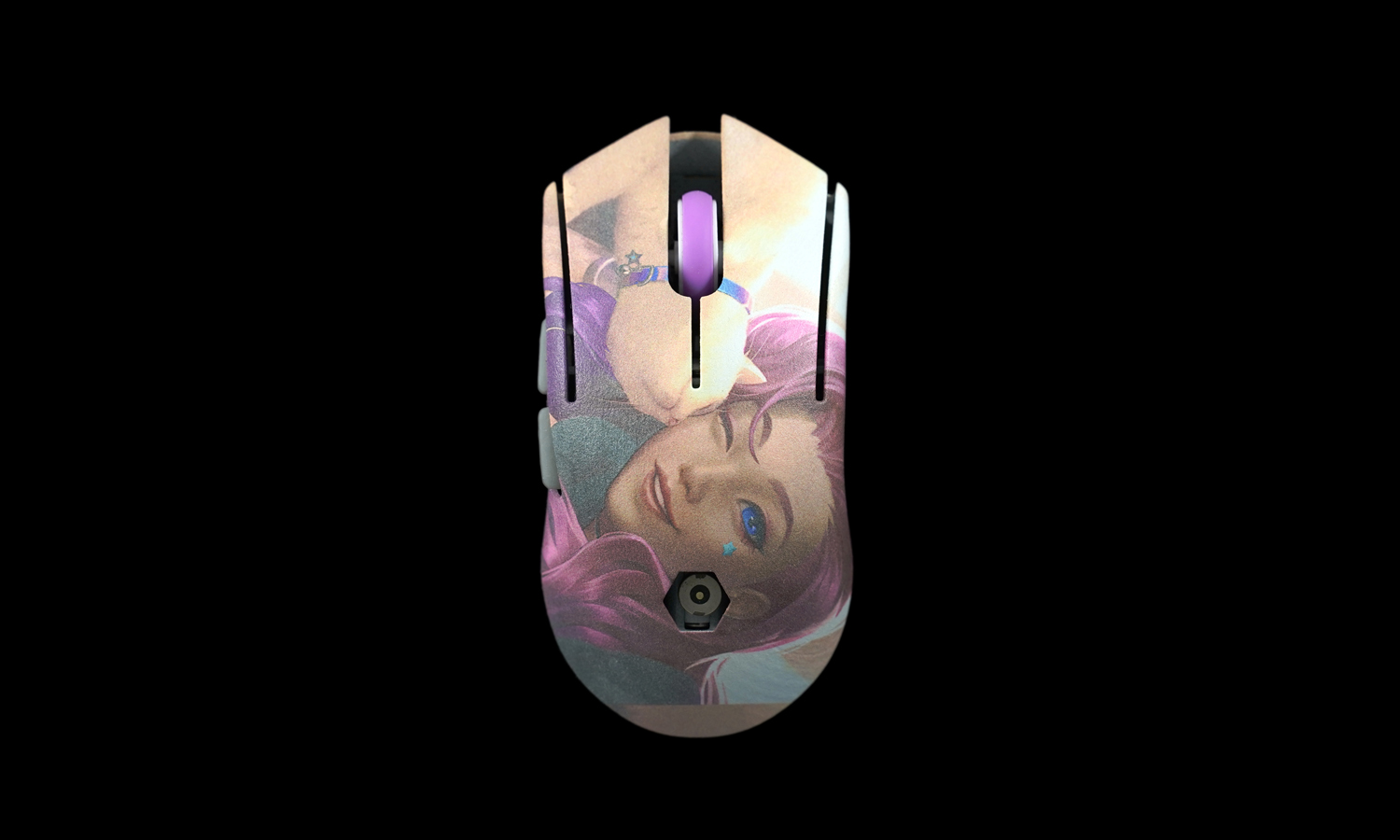

Are you a fan of League of Legends and Seraphine? Do you want to have a gaming mouse that matches her style and personality? If so, you will love this full-color gaming mouse shell made by FacFox with HP nylon and MJF 3D printer.

This mouse shell features the patterns of Seraphine, the starry-eyed songstress who can use sound magic and empathy to connect with others. The shell is made of high-quality nylon material that is matte and durable. It fits perfectly on your hand and gives you a smooth gaming experience.

FacFox is one of the 3D printing service providers that can offer full-color nylon printing services. You can print anything with curved shapes and fitting patterns without painting. Whether you want to customize your own gaming mouse, phone case, jewelry, or anything else, FacFox can make it happen:)

Visit FacFox website today and discover how you can unleash your creativity with full-color nylon printing service!

Solution

- Step 1: The model was designed and colors were assigned to different parts of it. Any color from the CMYK could be used.

- Step 2: It was then exported as a 3MF file, which was a format that supports full-color information.

- Step 3: Then, the 3MF file was uploaded to the HP SmartStream 3D Build Manager software, which prepared your model for printing by slicing it into thin layers and optimizing its orientation and placement on the build platform.

- Step 4: The nylon powder and the color agents were loaded into the HP Jet Fusion 300/500 series printer. The printer heated up the powder bed to just below its melting point and then deposited a thin layer of powder on top of it.

- Step 5: Next, the printer used an inkjet array to selectively apply color agents and a fusing agent onto the powder layer according to the 3D model. The color agents changed the color of the nylon powder while the fusing agent helped bond it together.

- Step 6: The printer used an infrared lamp to fuse the powder layer into a solid part. The lamp would only heat up where the fusing agent was applied, leaving the rest of the powder unaltered.

- Step 7: Finally, after repeating these steps for each layer of the 3D model, the finished model was removed from the printer and any excess powder was cleaned off. You could also post-process your part by sanding or polishing it if needed.