- SLA 3D Printed Shurato Hidaka Large Anime Figure

- LPBF 3D Printed SS316L Orthodontic Bracket Rapid Prototyping

Material Metal

Quantity 5 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

We recently completed a prototype watch case, fabricated using Selective Laser Melting (SLM) technology with SS316L stainless steel. This project aimed to evaluate the feasibility of 3D printing complex watch components and identify potential areas for improvement.

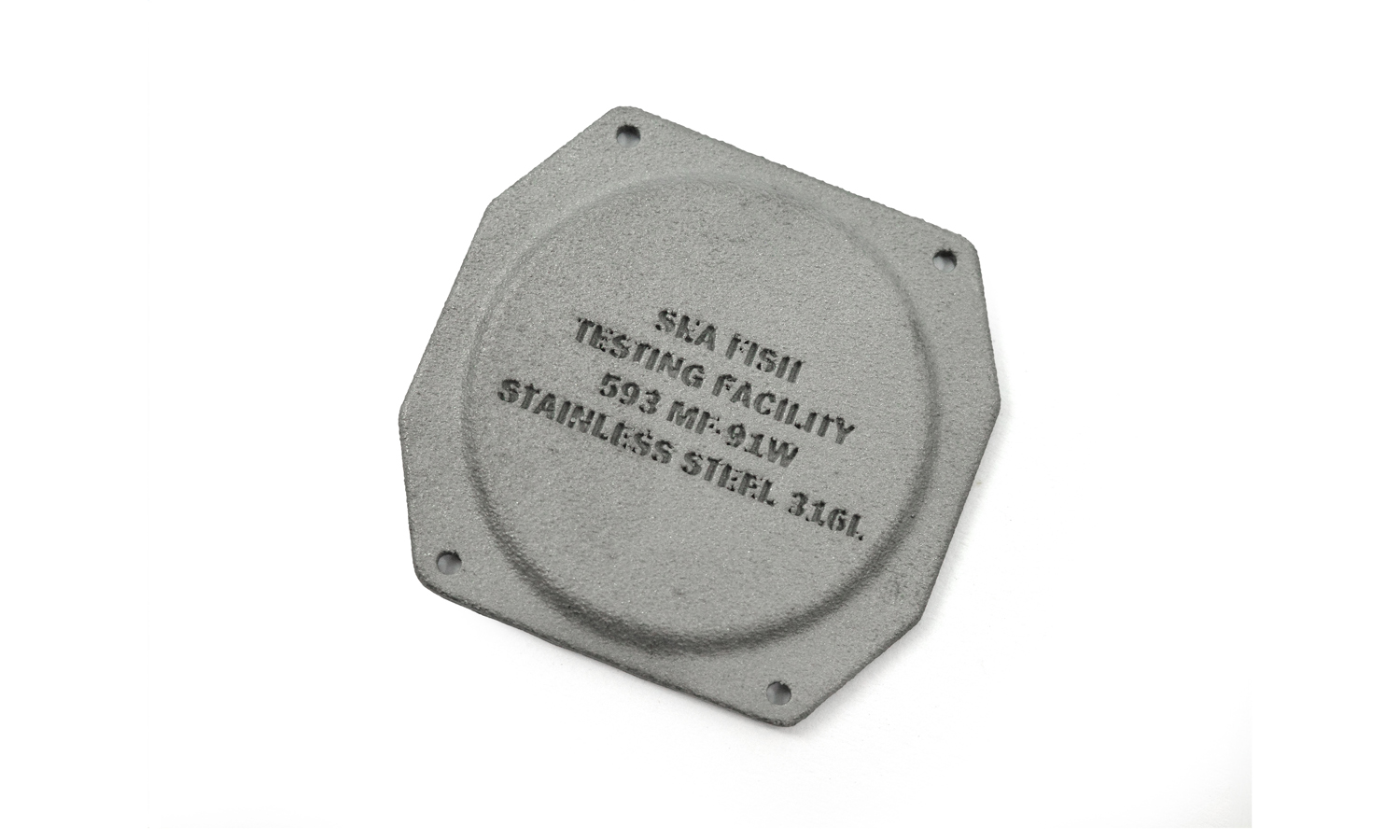

Back Case Analysis

The back case featured sunken letters, which were successfully identified but not printed with perfect detail. This revealed a limitation in the current SLM process, particularly when dealing with fine features. Our analysis suggests that a minimum detail thickness of at least 2mm is required to ensure adequate print quality.

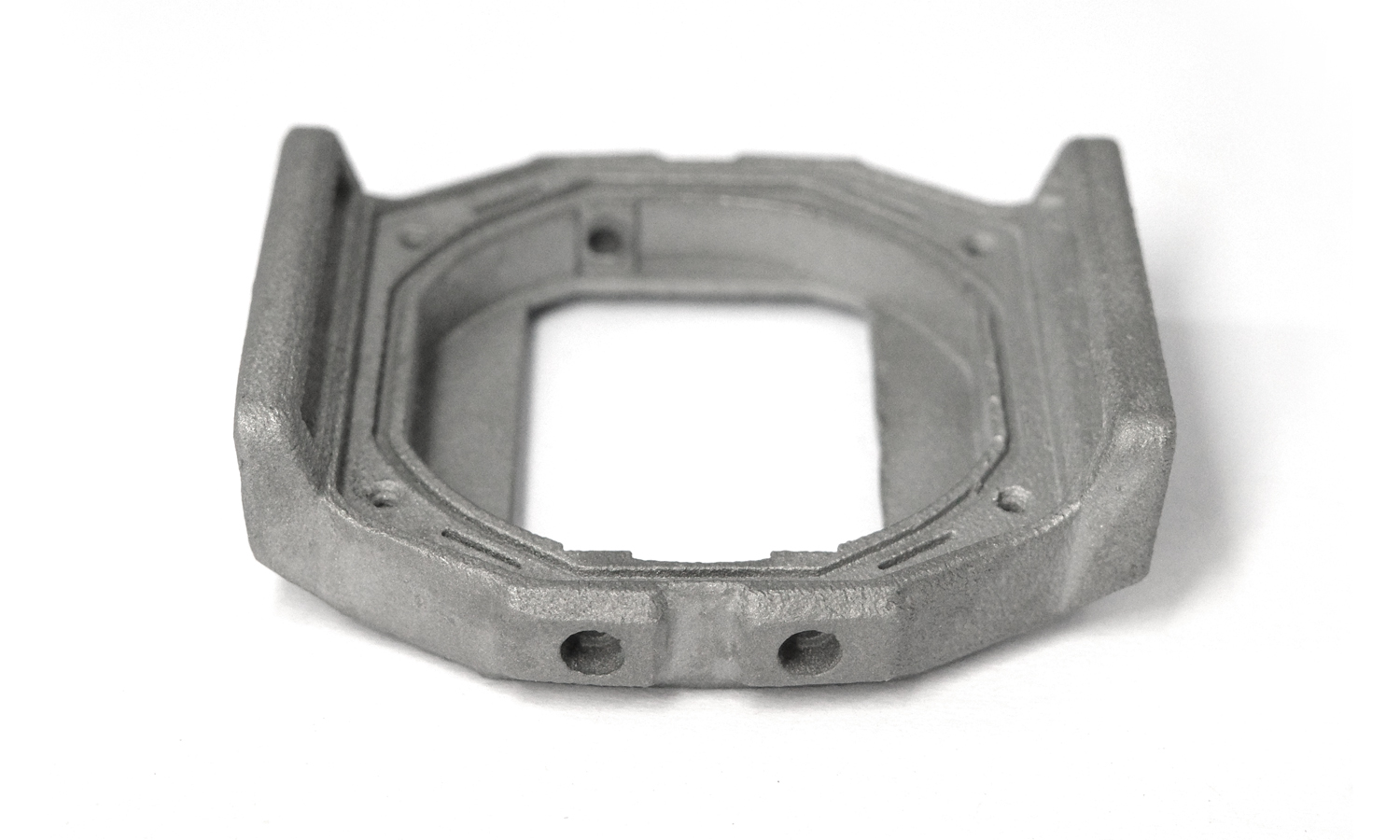

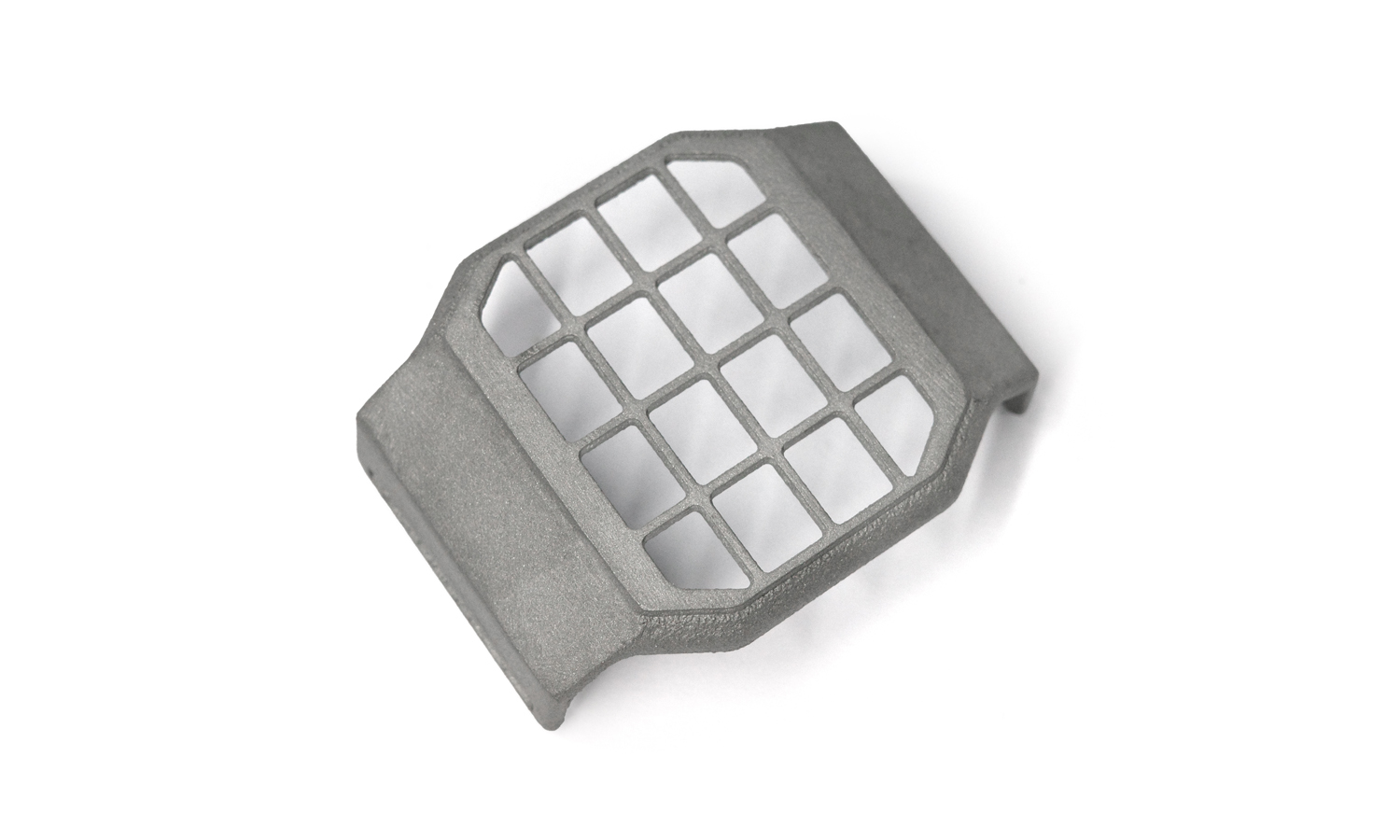

Front Case Variations

Three front cases were produced, each with a unique design. One case incorporated a grid structure, likely intended to enhance the watch’s durability by protecting the glass face from cracking or shattering. The other two cases had a standard design, but one was tapped according to the specified requirements.

Clasp Quality Issues

Unfortunately, the clasp did not meet our quality standards. We have scheduled a reprint to address the deficiencies and ensure it aligns with our expectations.

Conclusion

The SLM 3D printed SS316L watch case prototype has provided valuable insights into the capabilities and limitations of this technology for producing complex watch components. While the back case’s fine features presented challenges, the front cases demonstrated the potential of SLM for creating intricate and functional designs.

Interested in exploring metal 3D printing for your next project? FacFox offers a wide range of metal 3D printing services, including SLM, to meet your specific needs. Contact us today to discuss your project requirements and receive a personalized quote.

Solution

- Step 1: Design Creation.┬ĀThe watch case design was created using CAD software.

- Step 2: Preparation of Powder.┬ĀSS316L stainless steel powder was prepared and loaded into the SLM machine.

- Step 3: Layer Deposition.┬ĀA thin layer of SS316L powder was spread across the build platform.

- Step 4: Laser Melting.┬ĀThe laser selectively melted the powder according to the design, fusing it layer by layer.

- Step 5: Layer Repetition.┬ĀThe process of spreading powder and laser melting was repeated until the entire watch case was built.

- Step 6: Cooling.┬ĀThe completed watch case was allowed to cool down inside the machine.

- Step 7: Removal from Build Platform.┬ĀThe watch case was carefully removed from the build platform.

- Step 8: Support Removal.┬ĀAny support structures used during printing were removed.

- Step 9: Post-Processing.┬ĀThe watch case underwent post-processing steps such as polishing and heat treatment to achieve the desired finish and mechanical properties.

- Step 10: Inspection.┬ĀThe final watch case was inspected for quality and accuracy.