- SLA 3D Print Formlabs ESD Resin Electronics Cover

- SLA 3D Printed Formlabs Tough Resin 1500 Engineering Sample Part

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

Are you looking for a convenient and durable way to store your small items? Do you want a custom-made box that fits your needs and preferences? If so, you might be interested in the LCD 3D Print ABS-like Resin Compartment Box, a product that combines the advantages of resin 3D printing and ABS-like material.

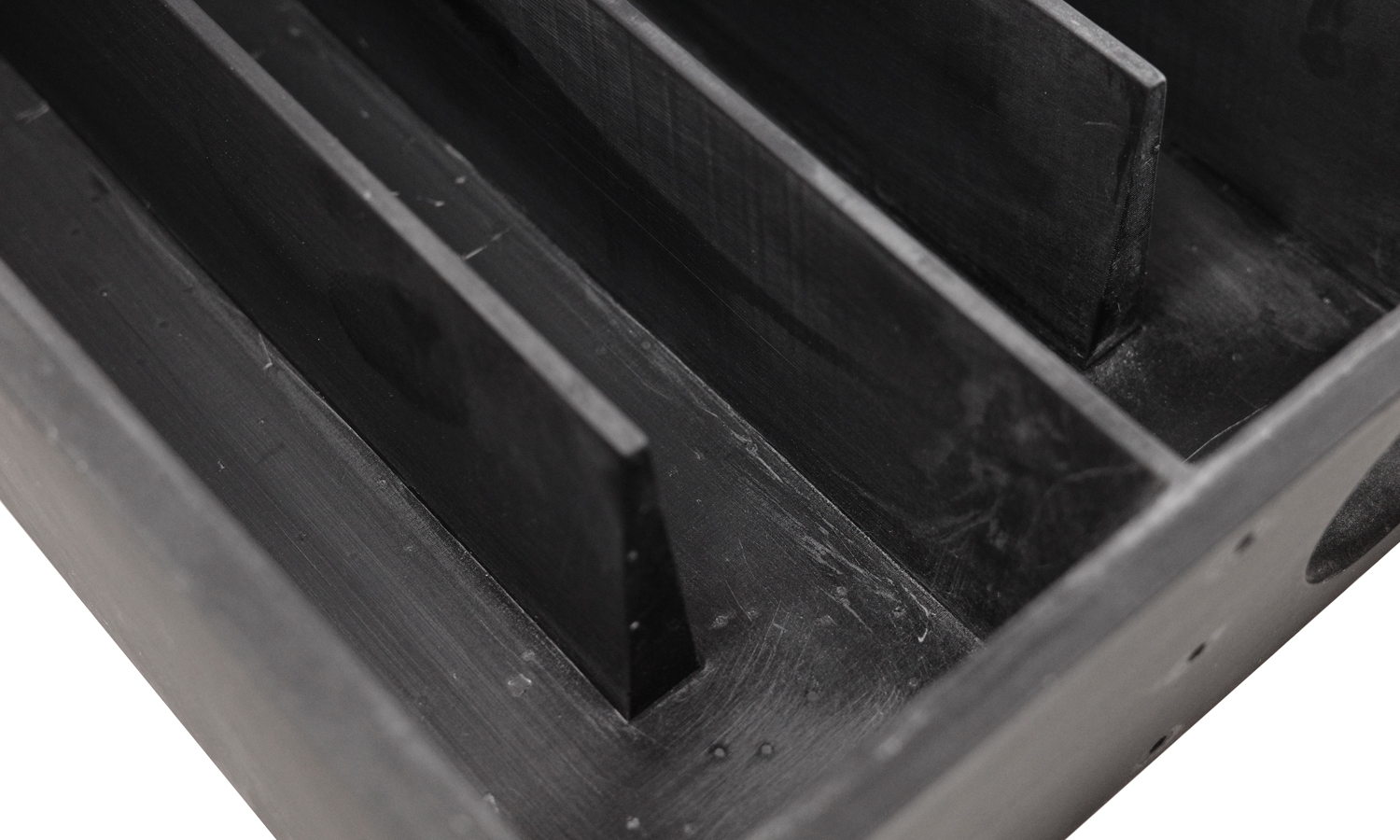

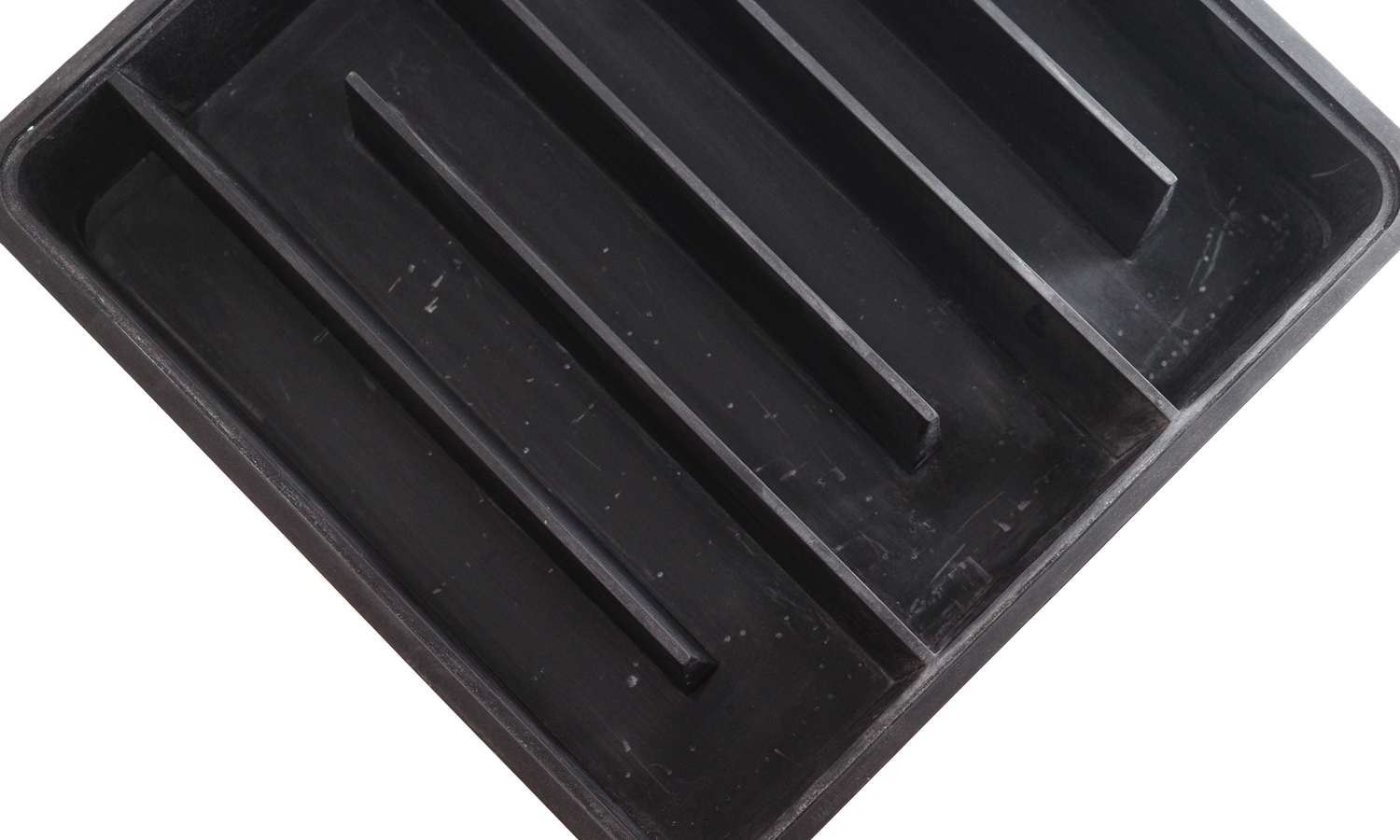

The LCD 3D Print ABS-like Resin Compartment Box is a box that measures about 30*30*10 cm and has six compartments inside. The box has a front panel that has one big round hole and six small holes. The box is ideal for storing things like jewelry, coins, screws, buttons, or any other small objects that you want to keep organized.

The box is made with LCD 3D printing technology, which uses a liquid crystal display (LCD) to selectively cure resin layers and create solid objects. LCD 3D printing is faster, more accurate, and more affordable than other resin 3D printing methods. The material used for the box is ABS-like resin, which mimics the properties of ABS plastic. ABS-like resin is strong, tough, heat-resistant, and easy to paint or sand. It also has a smooth surface finish and a high level of detail.

If you want to order your own LCD 3D Print ABS-like Resin Compartment Box, you can do so from FacFox, a leading online platform for resin 3D printing services. FacFox offers high-quality resin 3D printing at competitive prices, with fast delivery and excellent customer support. You can choose from a variety of colors and finishes for your box, and even upload your own design if you want to customize it further. FacFox will print your box with professional-grade LCD 3D printers and ship it to your doorstep in no time.

DonŌĆÖt miss this opportunity to get your own LCD 3D Print ABS-like Resin Compartment Box from FacFox. Visit their website today and place your order. You will be amazed by the results!

Solution

- Step 1: a 3D model of the box was created using CAD software. It┬Āwas sliced into thin layers using slicing software. The slicing software also generated the support structures and the exposure settings for each layer.

- Step 2: the sliced file was transferred to an LCD 3D printer, which used an LCD display module to project a certain light pattern onto a resin vat. The resin vat contained ABS-like resin, which was a photopolymer resin that mimicked the properties of ABS plastic. The resin was strong, tough, heat-resistant, and easy to paint or sand.

- Step 3: The LCD 3D printer started printing the box from the bottom up. For each layer, the LCD screen controlled the light pattern that was emitted from an LED lamp. The light pattern selectively cured the resin in the resin vat, forming a solid layer of the box. The build platform then moved up by one layer thickness, and a new layer of resin was spread over the previous layer by a roller. This process was repeated until the entire box was printed.

- Step 4: After the printing was completed, the box was removed from the build platform and washed with isopropyl alcohol to remove any uncured resin. The box was then cured further under a UV lamp to enhance its mechanical properties and durability.

- Step 5: the support structures were removed from the box using a pair of pliers or a cutter. The box was then sanded and painted as desired.