- SLA 3D Printed Monster with Elongated Head Resin Garage Kit

- SLA 3D Printed Pet Feeder and Water Dispenser Prototypes

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Gallery

About Project

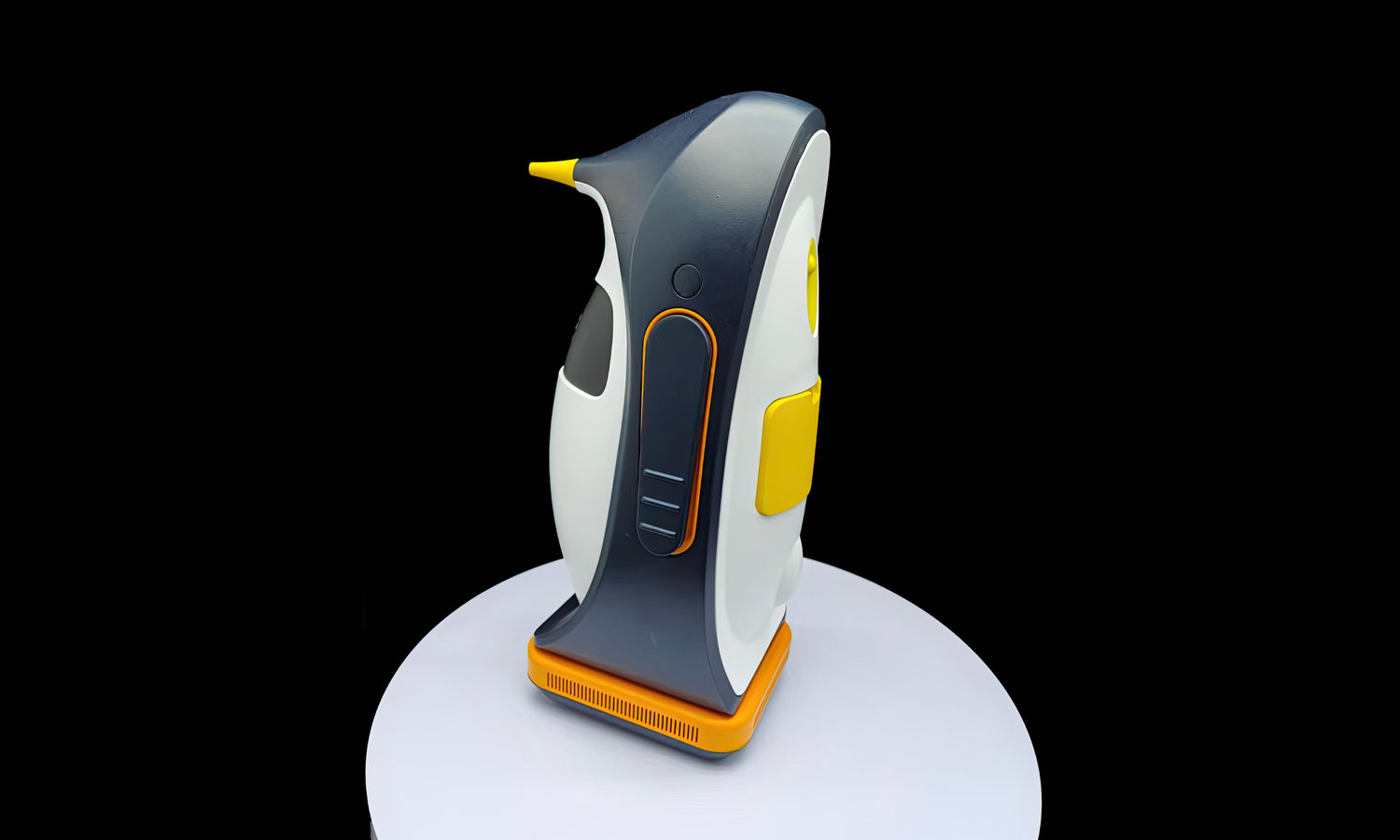

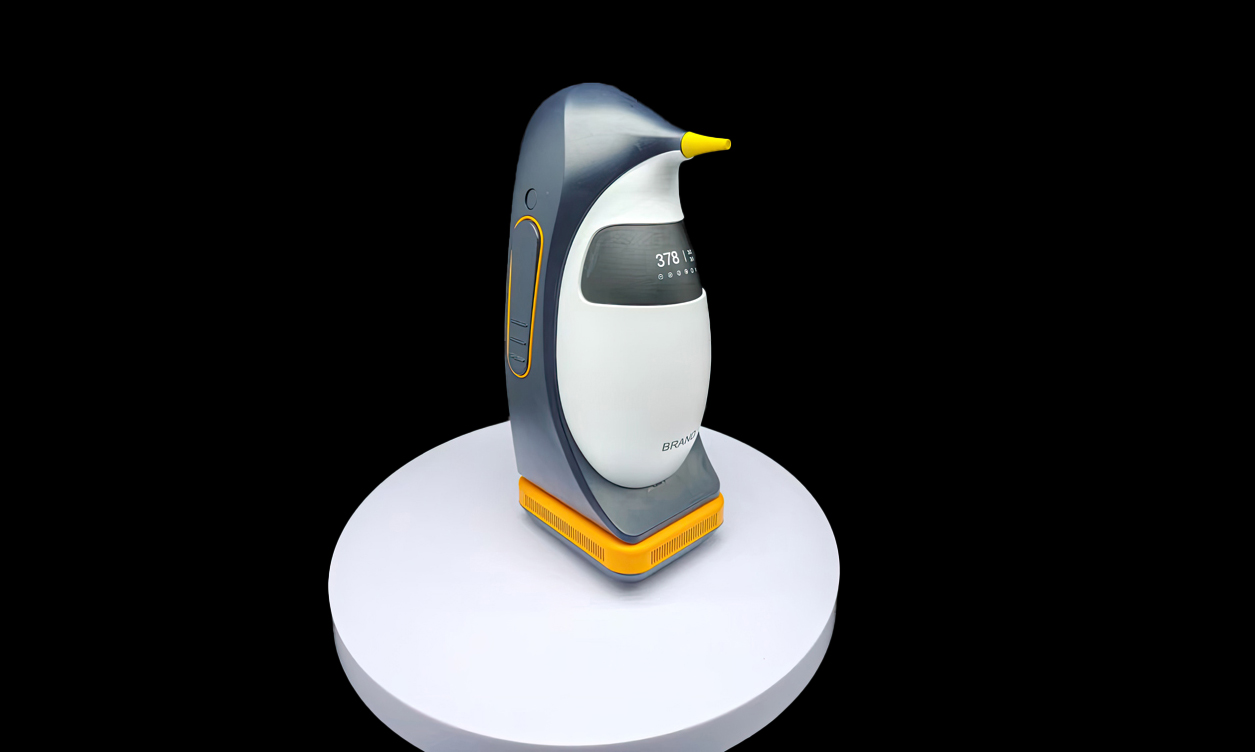

FacFox is proud to showcase a stunning SLA 3D printed prototype designed by a client for a student project. This adorable penguin-shaped humidifier air purifier is as functional as it is cute, boasting a sleek white and black body, a bright yellow beak-like structure, and a digital display indicating the air quality.

The model's innovative design features wings that function as caps, lifting up to reveal an orange transverse fringe grid for air intake. The replaceable yellow beak cleverly serves as the humidifier's vapor outlet, making it easy to maintain and clean. While this prototype focuses on visual appearance, it lays the groundwork for a fully functional air purifier and humidifier.

This project exemplifies FacFox's commitment to delivering exceptional 3D printing services for prototypes of all shapes and sizes. Our SLA printing technology utilizes high-quality resin to produce incredibly detailed and smooth models, ideal for showcasing intricate designs and visual concepts.

Here's what makes FacFox the go-to choice for prototyping:

- Advanced SLA Printing Technology: Achieve exceptional resolution and precision for prototypes that match your vision.

- Wide Range of Materials: Choose from a variety of resins to suit your specific project requirements.

- Expert Support: Our team is here to guide you every step of the way, from design for manufacturability (DFM) analysis to post-processing recommendations.

- Fast Turnarounds: Get your prototypes quickly and efficiently to keep your project on track.

Whether you're a student working on a school project, a designer bringing your vision to reality, or an entrepreneur developing the next big thing, FacFox is here to help you transform your ideas into prototypes.

Contact us today for a free quote and discover how our 3D printing expertise can take your project to the next level. Let's turn your innovative concepts into reality, just like this adorable penguin-shaped humidifier air purifier!

Solution

- Step 1: Design Preparation. The clientŌĆÖs design was finalized using 3dsMax software, ensuring all details such as the sleek penguin-inspired body, the yellow beak, and the digital display were included.

- Step 2: Resin Selection. A suitable resin for SLA 3D printing was chosen, prioritizing properties that would result in a smooth surface finish and the required structural integrity.

- Step 3: Printer Setup. The SLA 3D printer was prepared, with the build platform being calibrated to the correct position within the resin tank.

- Step 4: Layer-by-Layer Printing. The 3D model was sliced into thin layers, and each layer was printed by curing the resin with a UV laser. The build platform was moved incrementally to allow for the next layer to be cured on top of the previous one.

- Step 5: Wing Mechanism Fabrication. The wings, designed to lift and allow air passage, were printed with hinges or joints that enabled their movement.

- Step 6: Beak Manufacturing. The yellow beak, acting as the vapor outlet, was printed separately to ensure it was easily replaceable and cleanable.

- Step 7: Grid Creation. The orange transverse fringe grid, which allowed air intake, was printed with precision to fit seamlessly below the wings.

- Step 8: Assembly. All printed parts were carefully cleaned of excess resin, and the wings and beak were assembled onto the main body of the prototype.

- Step 9: Post-Processing. The prototype underwent post-processing, which included washing, curing, and surface finishing to achieve the desired aesthetic and functional qualities.

- Step 10: Quality Check. The completed prototype was inspected for any defects and to ensure all moving parts functioned as intended.

- Step 11: Display Preparation. Finally, the prototype was mounted for display, showcasing the design without any internal structure, purely for visual presentation.